CNC cutting parameters are a key aspect of computer numerical control (CNC) processing because they directly affect the quality, efficiency and cost-effectiveness of the manufacturing process. In CNC machining, the cutting parameters refer to variables that control the movement of the cutting tool, such as feed rate, spindle speed and cutting depth. Optimizing these parameters is critical to achieving the desired results, including accuracy, finishing and tool life.

Understanding the interaction between different cutting parameters is crucial for CNC mechanics and manufacturers. For example, increasing feed rates can increase productivity but can damage surface finishes and tool life. Similarly, spindle speeds affect the performance of the cutting tool, with higher speeds suitable for softer materials and lower speeds used for hard materials. On the other hand, the depth of the cutting affects the engagement of the cutting tool and the resulting surface finish.

To optimize CNC cutting parameters, the manufacturer considers a variety of factors, including the type of material being processed, the geometry and materials of the cutting tool, and the machine tool functionality. Material properties such as hardness, toughness and thermal conductivity play an important role in determining the optimal cutting parameters. For example, harder materials may require lower feed rates and cutting depths to prevent tool wear, while softer materials can withstand higher feed rates and cutting depths.

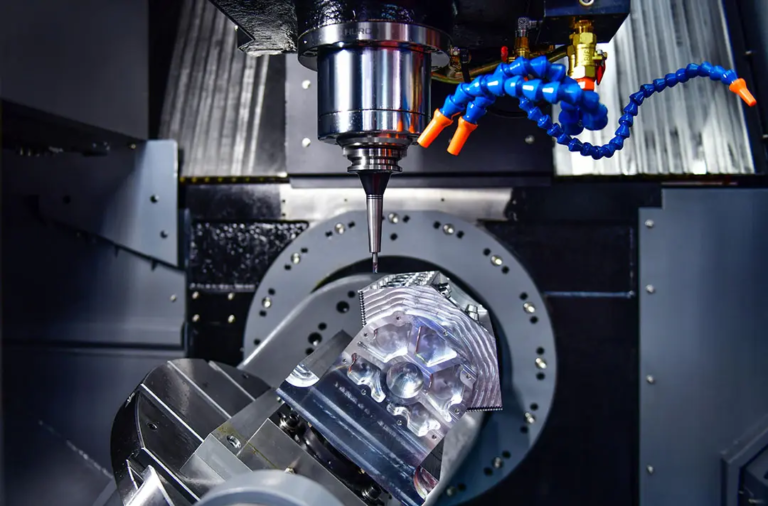

Advanced CNC machining techniques such as five-axis machining introduce new complexity and opportunities to optimize cutting parameters. Five-axis machining allows multiple axes to be moved simultaneously, allowing for the creation of complex geometries and surfaces. However, this complexity requires more complex cutting parameter optimizations, given the interaction between multiple axes and the resulting tool path.

Light Light, a professional five-axis CNC machining manufacturer, has developed expertise in cutting parameters for a variety of materials and applications. With advanced five-axis CNC machining equipment and production technology, Great Light can quickly customize and process materials, providing one-stop post-processing and completion services. Their expertise in CNC cutting parameters enables them to deliver high-quality precision parts with improved surface finishes, reduced tool wear and improved productivity.

In short, optimizing CNC cutting parameters is a key aspect of CNC machining, requiring in-depth understanding of material properties, cutting tool geometry and machine tool functionality. By carefully balancing feed rate, spindle speed and cutting depth, manufacturers can improve productivity, accuracy and surface finishes. As CNC machining technology continues to develop, the importance of optimizing cutting parameters will only continue to grow, driving innovation and excellence in the manufacturing industry.

FAQ (FAQ)

Q: What are CNC cutting parameters and why are they important?

Answer: CNC cutting parameters refer to variables that control the movement of the cutting tool, such as feed rate, spindle speed and cutting depth. Optimizing these parameters is critical to achieving the desired results, including accuracy, finishing and tool life.

Q: How does material properties affect CNC cutting parameters?

A: Material properties (such as hardness, toughness and thermal conductivity) play an important role in determining the optimal cutting parameters. Harder materials may require lower feed rates and cutting depths, while softer materials can withstand higher feed rates and cutting depths.

Q: What is the significance of five-axis machining in optimizing cutting parameters?

A: Five-axis machining introduces new complexity and opportunity to optimize cutting parameters, requiring more complex cutting parameter optimization to illustrate the interaction between multiple axes and the resulting tool path.

Q: How do manufacturers optimize CNC cutting parameters for their specific applications?

A: Manufacturers can optimize CNC cutting parameters by considering factors such as material properties, cutting tool geometry and machine tool functionality. They can also work with experienced CNC processing manufacturers such as Light Light to leverage their expertise and advanced technology.

Q: What are the benefits of optimizing CNC cutting parameters?

A: Optimizing CNC cutting parameters can improve productivity, accuracy and finish, reduce tool wear and improve cost efficiency. By achieving these benefits, manufacturers can enhance their competitiveness and provide high-quality products to their customers.