CNC cork processing services are a professional form of CNC machining that involves the use of computer numerical control technology to accurately cut and shape cork materials. Cork is a natural, elastic and versatile material that is a natural, elastic and versatile material that is uniquely insulated, soundproof and sealed to various industries including aerospace, automotive, construction and consumer products, including aerospace, automotive, construction and consumer products. The accuracy and versatility provided by CNC machining makes it an ideal way to process corks into complex shapes and designs that meet specific application requirements.

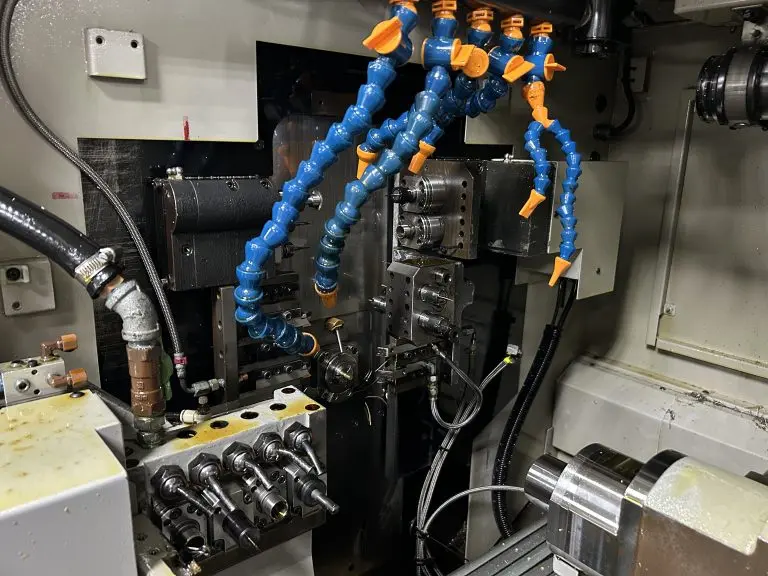

The core of CNC cork processing services is the utilization of advanced five-axis CNC processing equipment. This technology allows for the processing of complex geometric shapes and shapes that traditional processing methods will be difficult or impossible to achieve. The five-axis function means that the cutting tool can be moved in five different directions (three linear axes and two rotation axes), providing unparalleled flexibility and precision during the manufacturing process. This is especially beneficial for cork, a material that can be challenging due to its softness and collapse.

Professional manufacturers like Great Light, with advanced five-axis CNC machining equipment and extensive experience in production technology, can solve complex problems related to cork machining. They provide one-stop solutions for precision parts manufacturing, including post-processing and finishing services to ensure that the final product meets the highest standards of quality and accuracy. The ability to customize and handle a wide range of materials is an important advantage to quickly prototyping and producing to meet tight deadlines.

For industries that require custom precision machining, working with a well-known CNC machining service provider is a strategic decision. Their expertise and ability in five-axis CNC machining ensures the exact specification of precise parts, whether it involves complex design or mass production. The combination of advanced technology, skilled personnel and customer-centric approach makes them ideal for businesses seeking high-quality, customized cork parts at competitive prices.

The process of CNC Cork machining involves several key steps, including design, programming, machining and inspection. The initial design phase is critical, where computer-aided design (CAD) software is used to create digital models of the parts to be processed. This design is then converted into a set of instructions that the CNC machine can understand, so that cork material can be accurately cut and shaped. The use of CNC technology ensures that the processing process is highly accurate and repeatable, minimizing errors and reducing material waste.

In short, CNC cork processing services represent a significant advancement in the processing and manufacturing of cork products. By leveraging the capabilities of five-axis CNC machining, manufacturers can create complex shapes and designs with unparalleled accuracy and speed. For businesses and industries that rely on custom cork parts, working with professional CNC machining service providers can provide many benefits, including enhanced product quality, reduced production time and improved cost competitiveness. Whether used in aerospace, automotive or consumer products, CNC cork processing positions itself as an important part of the manufacturing supply chain.

FAQ

-

What is CNC hose processing?

CNC cork processing refers to the use of computer numerical control technology to accurately cut cork materials into specific designs and shapes.

-

What are the benefits of using CNC machining for cork?

Benefits include high precision, the ability to create complex shapes, reduced production time and minimal material waste.

-

What types of cork products are used in CNC-processed in industries?

Industries such as aerospace, automotive, construction and consumer goods use CNC-machined corks for insulation, sound insulation and sealing characteristics.

-

How to enhance the manufacturing process by five-axis CNC machining?

Five-axis CNC machining allows cutting tools to move in five different directions, allowing for the creation of complex geometric shapes and shapes with high precision and speed.

-

Can CNC machining services provide post-processing and completion services for cork products?

Yes, many professional CNC machining service providers, such as Light Light, offer one-stop solutions including post-processing and completion services to ensure high-quality final products.

- What factors should be considered when choosing a CNC Cork processing service provider?

Factors to be considered include providers’ experience in cork processing, technology and equipment functionality, quality control measures, and customer service reputation.