In recent years, the advent of 3D printing technologies has transformed various industries, paving the way for innovative applications in fields ranging from aerospace to healthcare. Among these advancements, the use of titanium in 3D printing has emerged as a game-changer, particularly in the realm of strength applications. A recent breakthrough in this domain has unlocked the potential for creating exceptionally durable and lightweight components that could redefine standards in design and manufacturing.

The Intriguing Properties of Titanium

Titanium, known for its exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, has been a hallmark material in high-performance applications such as aerospace engineering and medical implants. Its lightweight nature makes it an ideal choice for industries where reducing weight without compromising strength is critical.

However, traditional manufacturing methods for titanium can be labor-intensive, time-consuming, and costly, often limiting its widespread application. The introduction of additive manufacturing, particularly 3D printing, to process titanium has led to a shift in how this versatile metal is utilized.

What Sets This Breakthrough Apart?

The recent breakthrough in 3D printed titanium strength applications involves the development of new alloys and printing techniques that maximize the intrinsic properties of titanium while overcoming the limitations of prior methods. Researchers have been focusing on optimizing processes like selective laser melting (SLM) and electron beam melting (EBM) to improve the mechanical properties of printed components.

One significant aspect of this breakthrough is the advancement in alloy compositions. By engineering titanium alloys that incorporate elements such as aluminum and vanadium, researchers have crafted materials that exhibit enhanced tensile strength and fatigue resistance. These advances are critical, particularly in industries where components face extreme conditions, such as aircraft engines and structural components in aerospace applications.

The Role of Microstructure

Understanding the microstructure of 3D printed titanium is crucial to unlocking its full potential. The properties of titanium can be significantly influenced by the size and arrangement of its microstructures, which can be tailored during the printing process. The breakthrough entails the ability to control and manipulate these microstructures at a granular level, enabling engineers to produce parts that not only meet but exceed the mechanical standards required in demanding applications.

For example, by adjusting the thermal conditions during the printing process, researchers have found they can influence grain size—smaller grains often lead to enhancements in strength and toughness. This level of control allows for the fine-tuning of properties suited for specific applications, which was previously challenging to achieve with traditional manufacturing techniques.

Applications in Aerospace

The aerospace industry stands to benefit immensely from advances in 3D printed titanium. The need for lightweight yet strong materials has reached an all-time high, driven by the demand for more fuel-efficient aircraft. Using 3D printed titanium components can contribute significantly to reducing overall aircraft weight, leading to lower fuel consumption and emissions.

Manufacturers are already experimenting with using 3D printed titanium parts in critical components such as engine brackets, fuel nozzles, and structural frames. By replacing traditionally manufactured components with 3D printed equivalents, companies can streamline their supply chains and reduce lead times, enhancing production efficiency.

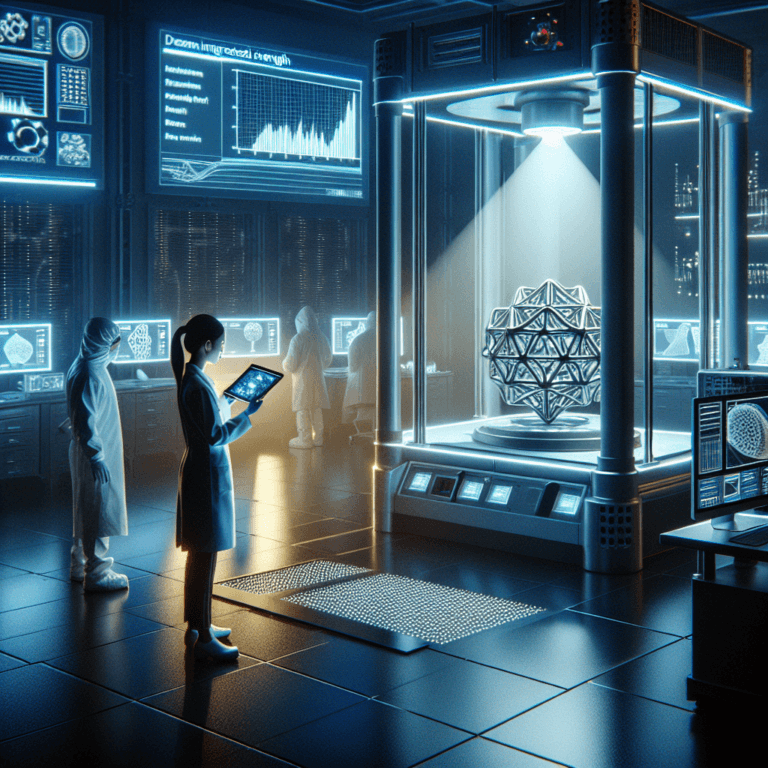

Additionally, the ability to create complex geometries through 3D printing allows for designs that were once considered impractical with traditional methods. This opens the door to innovations such as lattice structures that provide optimal strength while minimizing material usage. Such designs not only reduce weight but also improve performance.

Impacts on Medical Applications

Beyond aerospace, the medical field is on the cusp of a revolution thanks to breakthroughs in 3D printed titanium. Custom implants, prosthetics, and surgical instruments can be produced with remarkable precision, tailored to the individual patient’s anatomy. The biocompatibility of titanium makes it a natural choice for implants, but traditional manufacturing methods often limit the ability to create intricate custom designs.

3D printing allows for a level of personalization that was previously unattainable, reducing the risks of rejection and complications. For instance, orthopedic implants can be designed to fit precisely into a patient’s bone structure, improving healing times and outcomes. Furthermore, the use of titanium in dental implants has also seen significant advancements, with custom shapes and designs that enhance aesthetic appeal and functional performance.

Considerations for Sustainability

With the growing emphasis on sustainability in manufacturing, the ability to use titanium efficiently through 3D printing cannot be overlooked. Traditional methods often result in a significant amount of waste, whereas 3D printing optimizes material usage by adding only what is necessary to create the desired component. Additionally, the focus on lighter components translates to energy savings in various applications, particularly in transportation.

Researchers are also exploring ways to recycle titanium powder used in 3D printing, further enhancing the sustainability profile of this technology. The closed-loop systems that can be developed around these processes promote a circular economy, reducing the environmental impact associated with titanium sourcing and manufacturing.

Challenges Ahead

Despite the promising advancements, there are challenges to address for the widespread adoption of 3D printed titanium components. The technology is still relatively new, and as such, standardization is necessary to ensure consistency and reliability in printed parts. Industries such as aerospace are subject to rigorous testing and certification processes, and establishing robust standards for 3D printed titanium is paramount.

Moreover, while the cost of 3D printing has decreased over time, titanium remains one of the more expensive materials to source and process. Developing cost-effective methods for producing titanium powder and optimizing the printing process will be vital in making this technology accessible to a broader range of industries.

Future Outlook

The future of 3D printed titanium is bright, with ongoing research and development promising to further enhance its applications across various sectors. Collaborative efforts between academia, industry leaders, and manufacturers are key to pushing the boundaries of what is possible with titanium 3D printing technology.

As the technology matures, we can expect to see even more sophisticated alloys, enhanced printing processes, and expanded applications in sectors beyond aerospace and medical, including automotive, energy, and beyond. This breakthrough not only heralds a new era for design and manufacturing but also exemplifies the incredible potential of additive manufacturing technologies to revolutionize our approach to problem-solving in engineering and materials science.

In conclusion, the breakthroughs in strength applications of 3D printed titanium signify a remarkable leap forward in material science and engineering. By harnessing the unique properties of titanium through advanced 3D printing methods, industries can embark on a path toward more efficient, sustainable, and innovative designs. With ongoing research and technological advancements, the possibilities are endless, heralding a promising future for strength applications in 3D printing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.