Eradicating Vibration and Noise in CNC Double-Pin Vertical Machines: A Comprehensive Guide to Diagnosis and Repair

In the world of precision machining, the need for reliable and efficient equipment is paramount. However, even the most advanced machines can fall prey to vibration and noise defects, resulting in decreased productivity, increased downtime, and reduced overall performance. This is particularly true for CNC double-pin vertical machines, which are designed to precision-craft intricate components with exacting specifications. In this article, we’ll delve into the diagnosis and treatment of vibration and noise defects in CNC double-pin vertical machines, focusing on both electrical and mechanical aspects.

Diagnosing the Issue: A Multi-Faceted Approach

Before embarking on the repair process, it’s essential to identify the source of the vibration and noise. In most cases, the problem lies at the intersection of mechanical and electrical components, making a comprehensive diagnosis crucial.

Electrical Diagnostics

Vibration and noise during deceleration often indicate issues with the driving system, such as a faulty regenerative circuit in the AC reader. Conversely, problems at constant speed may point to mechanical wear or misalignment. Additionally, electrical defects can arise from:

- Loss of supply phase

- Abnormal power supply

- Error adjustment of the supply switch in the control unit

- Incorrect adjustment of the gain circuit in the servomotor unit

- Tremor circuit errors

Mechanical Diagnostics

On the mechanical side, potential causes of vibration and noise include:

- Loose connection screws between the pin box and the bed

- Pre-service force load too large

- Worn or damaged bearings

- Incorrect dynamic balance of the spindles

- Faulty gear adjustment

- Insufficient lubrication

- Looseness in the belt or coupling

- Excessive load or uneven foundation

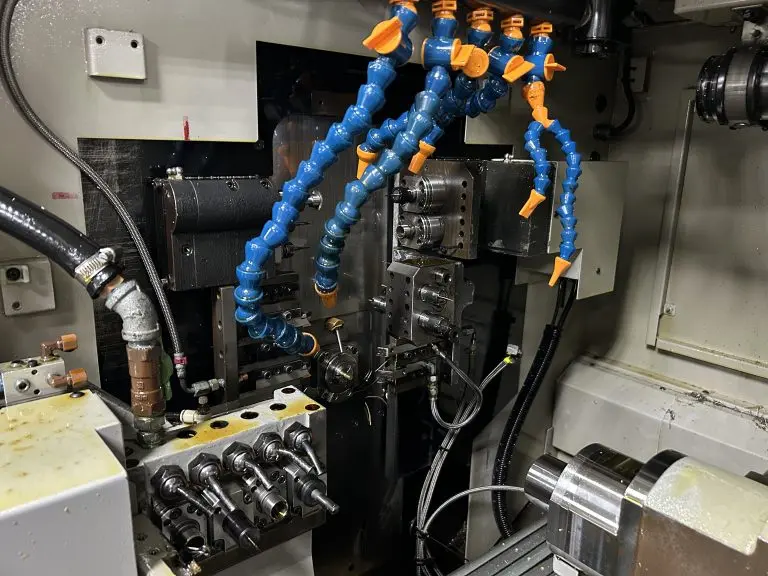

Repairing the Issue: A Step-by-Step Guide

To address vibration and noise problems in CNC double-pin vertical machines, a methodical approach is necessary. Ensure that the supply voltage is stable, the control unit is adjusted correctly, and the servomotor unit circuit is adjusted optimally. For mechanical issues, address the following:

- Tighten connection screws: Secure the pin box and bed for optimal alignment and vibration reduction.

- Adjust rolling pretension force: Optimize bearing performance by adjusting the rolling load.

- Replace damaged bearings: Identify and replace worn or damaged bearings to eliminate vibration sources.

- Realign and re-balance the spindles: Adjust the dynamic balance of the spindles to achieve optimal performance.

- Adjust or replace gear: Ensure accurate gear alignment and replace worn or damaged components.

- Improve lubrication conditions: Regularly maintain lubrication systems to prevent heat buildup and reduce vibration.

- Tighten belt and coupling: Secure loose belts and couplings to eliminate vibrations and premature wear.

- Reduce load and foundation inspection: Regularly inspect the foundation and ensure it’s free from sinking, settlement, and lubrication issues.

Additional Considerations for Optimal Performance

During processing, select the appropriate tool and ensure it’s securely installed. Reduce cutting speed and power to minimize the impact of cutting force on the equipment. This proactive approach will help maintain the performance of your CNC double-pin machine and prevent vibration and noise issues.

In conclusion, the diagnosis and treatment of vibration and noise defects in CNC double-pin vertical machines require a deep understanding of both electrical and mechanical aspects. By implementing the strategies outlined above, manufacturers can ensure optimal performance, increased productivity, and reduced downtime in the pursuit of precision and innovation.