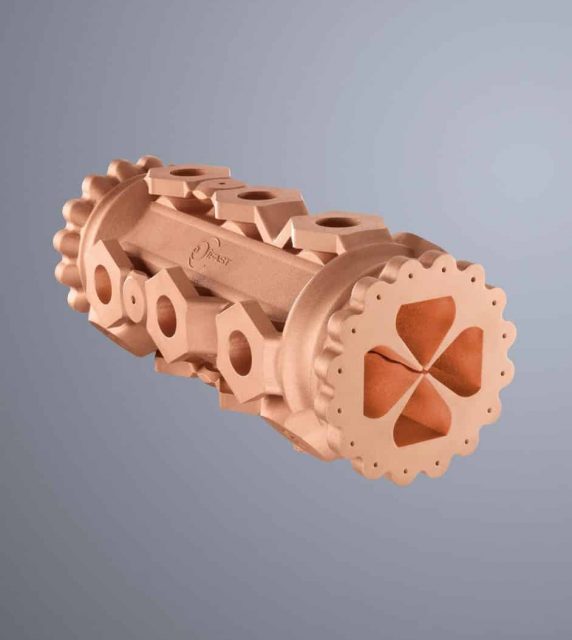

2022Year11month, in the next Next form upper, metal 3D printer manufacturerASSETThe core components of a complete particle accelerator will be shown, which is a3DOne piece copper printed parts, this project was created by CERN Coordinated funded by the EU I.FAST part of the project.3DPrinting technology enables complex RF quadrupole (price request)Copper components are manufactured in one piece.ASSETExpert in additive manufacturing Michael Thielmann He said: “This integrated printing proves that the machine we developed can manufacture large components with sufficient precision and is capable of printing very detailed details.400mm of large copper components, through 3D By printing, we can achieve faster, more economical and more energy-efficient manufacturing. “

This component is a radio frequency quadrupole (price request)which is one of the most complex components of an accelerator.Price request Providing energy to particle beams, bringing them closer to the speed of light. “There are currently more than 1,000 particle accelerators in operation around the world.30,000most of which are used in the healthcare and industrial sectors. Additive manufacturing can help reduce the size and cost of accelerators by improving their performance by improving the way they are manufactured and shortening their manufacturing time. “CERN of I.FAST project coordinator Maurizio Vretenar explain.

△ASSETPresentation of integrated copper produced by CERNPrice request

it’s not CERN The engineer uses it for the first timeAM. They have already used3D systemsThe machine prints thin-walled dot-matrix parts.Price request is financed as EU and CERN coordinated I.FASTDeveloped as part of the Accelerator (Advancing Innovation in Science and Technology) project. The objective of this strategic project is to enable Europe to develop and strengthen its leadership in the field of particle accelerators, in the service of science and society. advanced accelerator technology I.FAST works coordinatorTom Thorim “It is clear that in the future we will increasingly use components produced by additive manufacturing technologies in the accelerator sector,” noted.

Since CERNPolytechnic School of Milan,CNRS-IN2P3Fraunhofer IWS and Riga Technical University I.FAST A team of experts dedicated toASSETof TruPrint5000 Complex components are designed.Price request The requirements for the manufacturing process are very high. “It’s our TruPrint5000 This is where the green version comes into its own. This device uses a green laser to print the finest copper structures with consistently high quality while increasing productivity,”Thielmann explain.

Efficient, partially automated TruPrint 5000 3D Printing systems provide the ideal basis for industrial series production. With optional features including 500°C Warm up and equip three 500 With the full-field multilasers of Vartumkäf fiber lasers, you can cope perfectly with the most demanding industrial applications. The machine produces high-quality components made of different metal materials quickly and reliably and thus meets the high quality requirements of tool and mold manufacturing, especially in 3D Printing on preforms, aerospace and medical technology. As an option, the entire process chain can be carried out under a protective gas atmosphere: screening, printing, cooling, powder removal. In combination with external parts and powder management and monitoring solutions from TRUMPF,

Until now, suppliers have used traditional methods to CERN Manufactured in scientific laboratories and industry Price request. Many separate production steps such as milling and soldering are required, and these processes cost time and money. Additive manufacturing eliminates many intermediate steps. For example, when printing Price request TRUMPF systems can be built around empty spaces such as cooling channels.

Thielmannstates: “Using green lasers to make copper parts is faster than other systems using infrared technology. Copper absorbs green laser beams more easily, making it easier to process. Using green lasers requires less energy to be as fast as infrared lasers can work faster with the same energy, so users can additively manufacture copper components at lower cost using green lasers.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.