German Research Institute for Textile Fibers andARBURG GmbH + Co KG(Germany) are collaborating to develop an energy and material efficient solution.3DPrinting process for manufacturing sustainable composites reinforced with bio-based fibers.

In natural fiber composites, reinforcing fibers such as collagen or cellulose fibers are embedded in a matrix of lignin, hemicellulose or collagen. The fiber bundles align with the stress patterns. Tissues are formed primarily by physicochemical processes in solution at room temperature. Similar to nature, a new type of reinforced continuous fibers3DThe printing process also makes it possible to deposit the fiber strands in the right position (topology optimization) and in the right orientation depending on the load. However, natural fibers such as cellulose fibers are sensitive to higher temperatures. Therefore, they cannot be used in commonly used thermoplastics.3DProcessing takes place during printing.

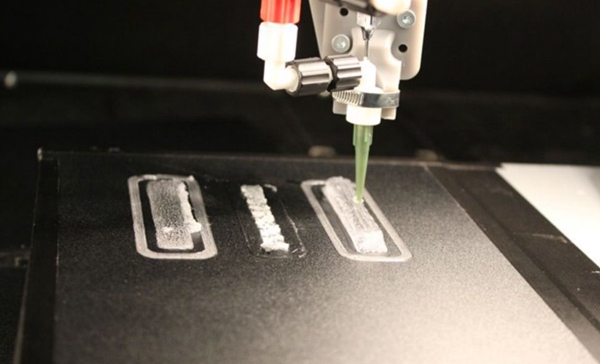

German Research Institute for Textile Fibers andArbourgThe result of the research work is3DPrinted fiber composite components made of continuous cellulose fibers embedded in a cellulose matrix. It is said that a new type of3DThe printing process allows composite materials to be manufactured at room temperature—This means that, just like in nature, materials and components can be produced simultaneously in a single operation at room temperature.

The strands of cellulose fibers are first stabilized with a binder to be processed in the printer. A specially designed print head converts the adhesive into a matrix continuously wrapped in cellulose. Since cellulosic fibers and matrix have similar chemical structures, this composite component is considered particularly stable. Its mechanical properties, such as resistance to breaking, are particularly good.

The solution-based and energy-efficient manufacturing method developed by the research team can also be used in other composite manufacturing processes. Particularly suitable for processing materials that are temperature sensitive and require high processing requirements, such as natural or cellulosic fibers.

Source: Chinese composites

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.