Unlocking Manufacturing Potential: A Comprehensive Guide to 5-axis CNC Machining Centers

Staying ahead in a dynamic world of precision manufacturing requires embracing the technology that pushes the boundaries of possible. The forefront of this innovation is the 5-axis CNC machining center. Gone are the days of relying solely on simpler 3-axis machines for complex parts. The 5-axis CNC machining center represents a quantum leap that offers unparalleled versatility, accuracy and efficiency, which revolutionizes the creation of complex and demanding components. This guide delves into the world of 5-axis machining, explores its operations, advantages, applications, and why Greatlight is your top partner in this advanced manufacturing field.

Understand the Power: What is 5-axis CNC machining?

CNC (Computer Numerical Control) machining is a subtraction manufacturing process where computer-guided tools remove materials from solid blocks to create the required parts. this "axis" Refers to the direction in which the cutting tool or workpiece can move relative to each other.

- Basic axis: Basic X, Y and Z axes define linear motion:

- X-axis: Usually left and right movements.

- Y-axis: Usually it is front and back movement.

- Z-axis: Usually move upwards (along the main axis).

- Add rotation: The 5-axis machining combines two additional rotation axes (usually marked A and B, A and C) so that the cutting tool or workpiece can be tilted and rotated. This eliminates the need for multiple settings to access all aspects of the part.

There are two main configurations:

- Table/Table: The rotating shafts (A and C) are located on the machine tool with the workpieces. The tool moves linearly with x, y, z.

- Head/Trunnion: The rotation shafts (A and B) are located at the spindle head, tilt and rotate the cutting tool itself. Tables usually only move in x and y (sometimes z is on the table).

- Table/Head: One rotating shaft (usually a cradle or tilted, b-axis) is on the table and the other rotating (C-axis) is on the head. This provides a huge working envelope feature.

How does 5-axis machining work? Precise motion

- CAD/CAM programming: Engineers designed parts for 3D CAD software. Using CAM (Computer Aided Manufacturing) software, convert the model into complex tool paths to define exact movement, speed, feed, and tool changes. For 5 axes, CAM software is essential for calculating all five axes while ensuring tool and workpiece clearance.

- Machine Settings: Clam the raw material (workpiece) firmly on the rotary table or fixed table of the machine. The appropriate cutting tool is loaded into the machine’s automatic tool changer (ATC).

- Simultaneous processing: The control unit executes the program. Unlike 3-axis machining, tools and/or workpieces move dynamically across all five axes simultaneously. This allows the tool to approach the workpiece from any direction in a single setup.

- Precise cutting: Advanced motors and feedback systems ensure accurate micron movement. The spindle rotates the cutting tool at high speed, and accurately removes material layer by layer according to the pre-programmed tool path. Complex contours, undercuts, deep cavity and intricate geometry can have high accuracy.

- Automatically complete: Often, machines can be unattended for a long time, including automatic tool changes to handle different machining operations (roughing, finishing, drilling, attack) over the same cycle.

Why 5-axis? Unparalleled advantages

Going beyond 3-axis or even 4-axis machining can unlock important competitive advantages:

- Reduce setup and lead time: The ability to composite geometry from almost any angle in a single fixture greatly reduces or eliminates the need for manual requantitation and repositioning. This translates directly into faster overall production time.

- Excellent accuracy and geometric freedom: Multiple settings inevitably introduce tiny misalignments (tolerance stack). One setting of the 5-axis ensures key features of machining relative to a single reference, thereby significantly improving the accuracy and geometric integrity of the part. It creates impossible shapes with fewer axes.

- Excellent surface: Optimizing tool orientation relative to the part surface allows the machine to maintain ideal cutting engagement. This results in a smoother finish, less manual completion requirements, and the ability to use shorter cutting tools (reduced deflection, better vibration damping).

- Complex geometric shapes make it simple: Prototype and production parts have the productivity of organic profiles, deep bags, composite angles, intricate turbine blades, impellers or multi-faceted implants.

- Improve tool life and efficiency: Maintain optimal cutting angles and use shorter tools to reduce vibration, tremor and uneven wear, thus extending tool life. Faster machining cycles and reduced manual intervention also improve overall process efficiency and throughput.

- Rigid enhancement of smaller/fragile parts: For refined parts, minimizing settings reduces handling risks. The machine also allows for more firm fixation of parts throughout the machining process.

Among them, 5-axis machining shines: key applications

The versatility of 5-axis machining makes it essential in many high-tech and demanding industries:

- aerospace: Structural components (frame, bracket), engine parts (glitter, impeller, turbine), landing gear components, complex housing. (lightweight alloy, titanium, inconel).

- car: Prototypes, sophisticated engine/transmission assembly, suspension parts, custom wheels, molds and molds. (Aluminum, steel, composite material).

- Medical and Dental: Orthopedic implants, surgical instruments, prosthetics, base/crown/bridge. (titanium, stainless steel, cobalt chromium, peep).

- Energy (oil and gas, turbine): Pump housing, valve body, complex manifold, turbine blades and blades, downhole tools. (Stainless steel, duplex steel, super alloy).

- defense: Weapon system components, optical housing, solid electronic housing, guidance system parts.

- Mold and mold making: Made complex injection molds, mold casting molds, blow-type molds with deep cavity and complex cores.

- General precision engineering: Complex prototypes, housings, actuators, fixing components require tight tolerances.

Choose Greatlime: Your trusted partner with advanced accuracy

When your project requires the functionality of 5-axis CNC machining, it is crucial to choose the right partner. Greglight is ready to have the expertise, competence and commitment to excellence required for the most challenging manufacturing requirements. That’s why we are First choice For custom precision machining:

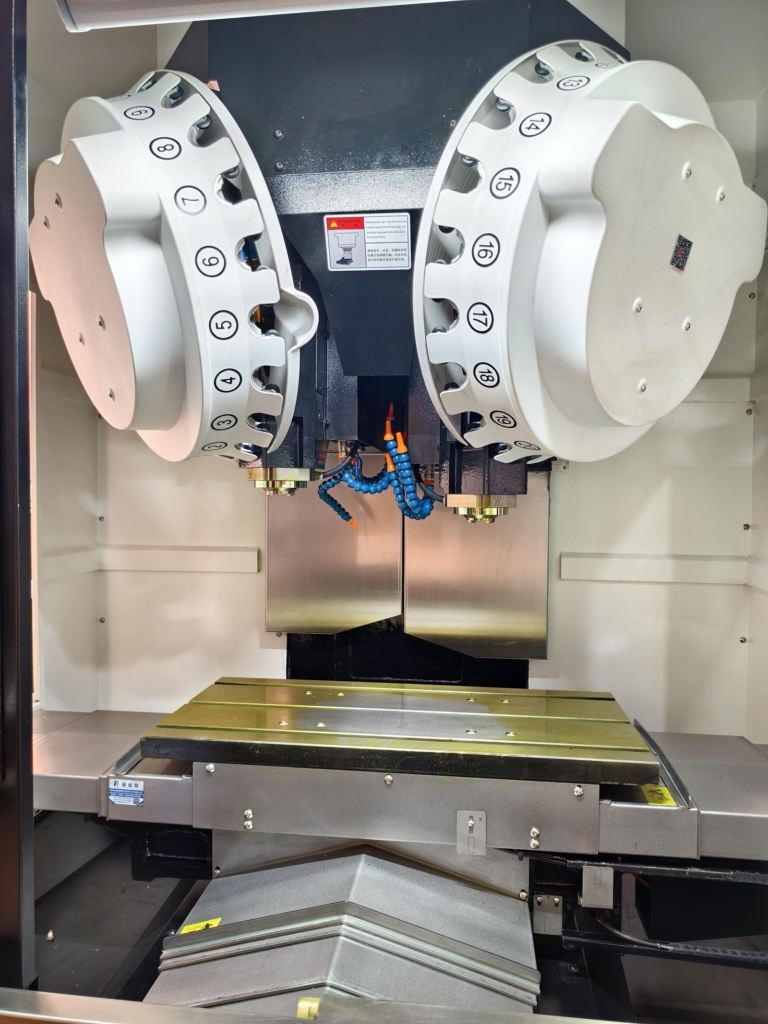

- State-of-the-art equipment and technology: We are constantly investing in advanced 5-axis CNC machining centers from leading manufacturers, equipped with the latest high-speed spindles, precision rotary tables (Trunnion or Table-Table), powerful control systems and automation tool changers. This ensures top-level accuracy and reliability.

- Master production technology: Our highly skilled engineers and mechanics have deep expertise in programming complex 5-axis tool paths using sophisticated CAM software, material selection, fixture design and process optimization. We transform your complex design into perfect finished parts.

- Comprehensive material solutions: We are skilled in using many metals including aluminum, stainless steel, carbon steel, tool steel, titanium, brass, copper and various exotic alloys. Tell us about your material requirements; we may have solutions.

- End-to-end service-one-stop shop: In addition to the original 5-axis machining, Greatlight also provides a complete set of post-processing and organization services:

- Deburing & Smoothing: Removes sharp edges and improves surface feel.

- Heat treatment: Annealing, hardening, tempering to achieve the desired material properties.

- Surface finish: Powder coating, anodizing (type II, type III), electroplating (nickel, chromium, zinc), passivation, polishing, bead/sand explosion.

- Special process: Laser engraving, painting, silk screening.

- assembly: Final assembly and testing (if needed).

- Quick customization and flexibility: We understand the need for speed. Our simplified processes and expertise enable us to respond quickly to custom processing requests, from small batch prototypes to medium batch production runs without sacrificing quality.

- No compromise competitive pricing: While 5-axis machining requires significant investment, Greathime Lever efficiency, scale and process optimization can provide excellent precision parts Best Price. We combine world-class capabilities with tangible value.

Conclusion: Embrace the future of precision manufacturing with great highlights

5-axis CNC machining is no longer just a niche capability. This is the basic tool to promote innovation and efficiency in modern manufacturing. Its ability to create complex, highly accurate parts in fewer settings can translate into faster market time, improve quality, and reduce the cost of complex components.

For businesses seeking unparalleled precision, geometric complexity, efficiency and top-notch surface finishes, working with truly capable 5-axis machining providers is essential. Greatlight demonstrates a firm commitment through our investment in cutting-edge equipment, deep technical expertise across different materials and industries, and our comprehensive one-stop post-processing service.

We are not just machine parts; we solve complex manufacturing problems and help bring visionary designs into reality. Partner with Greatlight as your Prime 5-axis CNC machining manufacturer. Contact us today to discuss your next custom precision machining project and experience the best price and performance guarantees. Customize precision parts now and unlock the full potential of advanced manufacturing.

Frequently Asked Questions about 5-axis CNC machining (FAQ)

Q1: What is the actual difference between 3-axis, 4-axis and 5-axis machining?

A1: It’s all about sports:

- 3 Axis: The tool moves x, y, z linear directions (left, front, back, up and down). Simple parts that require multiple settings for complex functions.

- 4 axis: Add a rotation axis (usually parallel to the X axis, called the A axis). Allows indexes (rotated to a fixed position) or sometimes rotated machining, suitable for cylindrical parts or machining sides without flipping.

- 5 axis: Add two rotation axes (usually A&C or A&B) that can move simultaneously. The tool or workpiece can be tilted and rotated continuously, accessing any side of a single setup for maximum complexity and efficiency.

Q2: Does 5-axis machining always produce finished parts in one setup?

A2: Although it is rapid reduce Settings are a key benefit, and this does not mean automatically one set up Each part. Very complex parts, even from a 5-axis perspective, hide features, or require very different machining strategies, require specific tool orientations or avoid clamping of fixtures, possible A second operation is required. However, the reduction is dramatic compared to the 3-axis.

Q3: Is 5-axis processing always faster than 3-axis?

A3: For complex parts: Absolutely. Eliminating multiple settings saves a lot of time. For simple parts: A machine using a 5-axis may not be required or cost-effective compared to a 3-axis machine dedicated to this simple geometry. Time savings mainly come from the ability to reduce the ability to set up and use more aggressive tool paths optimized for 5-axis.

Question 4: What typical tolerances can be achieved in a 5-axis CNC machining center?

A4: Modern, well maintained 5-axis machining center is very precise. Greatlight usually maintains tolerances +/- 0.001" (0.025 mm), even tighter For key features, it depends on part size, geometry, material and process control. The advantages of single setup play a huge role in maintaining tight tolerances between complex relationships.

Q5: Greatlight Machine [Specific Material, e.g., Inconel, Titanium, Aluminum]? What size?

A5: Yes! Greglight has extensive experience in processing a variety of metals, including Challenge Titanium, Inconel (718, 625), Hastelloy, Stainless Steel (303, 304, 316, 17-4ph), Aluminum (6061, 7075, etc.), Copper tubes, copper, copper and various tools. The maximum part size we can accommodate depends on the working envelope of our specific machine (usually provided according to RFQ). We combine material expertise with advanced processing strategies to effectively process these materials.

Question 6: Why partner with Greatlight in other stores that offer 5 axes?

A6: GRESTHIMENG passed:

- Cutting-edge technology: Continuous investment in the latest high-precision 5-axis technology.

- Deep technical expertise: A skilled engineer in 5-axis programming, fixture design and materials science.

- A true one-stop solution: Seamless integration of machining with all necessary post-processing finishes.

- Quick response and flexibility: Agile process for custom parts and prototyping.

- Competitive value: High precision and quality are provided at an optimized cost.

- Committed to solving problems: We focus on finding the best manufacturing solutions your Specific challenges.

Question 7: How do I start with a custom 5-axis CNC project in Greatlight?

A7: Very simple:

- Contact Us: Contact us via our website, email or phone.

- Share your request: Provide your CAD files (steps, IGES, SOLIDWORKS, etc.), drawings (specified tolerances, materials, finishes, quantities) and any special instructions.

- Comments and Quotes: If required, our engineering team will review the Design Design (DFM) and provide detailed quotes including cost and lead time.

- Approval and production: We will arrange production after you approve the quote and any DFM feedback. You will receive updates as needed.

- Quality and Delivery: Precision mechanism parts will undergo strict quality inspections before transportation and may be completed and ready for use.