Understanding Bend Radius

In sheet metal fabrication, the term bend radius refers to the inner curvature of a bend, measured from the inside edge of the bend to the centerline of the curve. While much attention is given to the minimum bend radius to avoid material cracking and ensure part integrity, the maximum sheet metal bend radius is just as critical. It defines the upper limits of curvature based on design requirements, tooling constraints, and material properties, and it plays a key role in achieving functional, durable, and aesthetically pleasing components.

Why Does Maximum Bend Radius Matter?

Design Flexibility and Structural Integrity

A larger bend radius is not merely a design choice—it is a strategic decision that affects both the structural performance and the aesthetic appeal of the final product. For applications requiring aerodynamic profiles, smooth curves, or elegant architectural forms, a large radius is essential. This flexibility allows engineers to tailor components for optimal stress distribution and load-bearing performance, ensuring that parts remain robust under operational conditions. Additionally, the capability to achieve large radii can enhance the overall visual harmony of custom sheet metal designs.

Tooling Constraints and Material Behavior

The maximum bend radius is also determined by the limitations of the available tooling. Traditional equipment such as press brakes, along with modern innovations like 5-axis CNC machining services, have physical limits defined by the size of their dies or bending tools. Softer materials, such as aluminum, generally allow for larger bend radii compared to more brittle materials like stainless steel. The interplay between material ductility, thickness, and the physical limitations of bending machinery guides engineers in selecting the optimal radius for their projects.

Factors Affecting Maximum Bend Radius

Material Type and Thickness

The type of metal and its thickness are primary factors in determining the feasible maximum bend radius. Ductile materials—such as copper or soft aluminum—allow for larger radii without compromising structural integrity. Conversely, thicker sheets or more brittle metals may require specialized techniques or tools to achieve desired curvatures without inducing stress or deformation.

Tooling and Machinery Options

The capability to achieve a specific bend radius largely depends on the machinery at your disposal.

-

Press Brakes: The maximum bend radius with press brakes is limited by the width of the die. Larger dies can help achieve broader curves, but there is a physical threshold that cannot be surpassed with standard equipment.

-

Rolling Machines: For cylindrical shapes or very large radii, rolling machines are often the tool of choice, delivering smooth, consistent curves that are difficult to replicate with conventional press brakes.

-

5-Axis CNC Machining Services: Advanced fabrication centers, such as those provided by leading sheet metal fabrication factories, utilize 5-axis CNC machining. These systems offer unmatched precision and flexibility, enabling the creation of complex or very large-radius bends that would otherwise be unachievable.

Bending Methods

Different bending methods influence the maximum radius that can be achieved:

-

Air Bending: Offers flexibility and is well-suited for applications where precise control over the bend angle is required; however, it is typically constrained by the available tooling setup.

-

Rotary Bending: Delivers consistent, large-radius curves, making it ideal for parts that demand uniform bending over extended lengths.

-

Edge Rolling: Often employed in architectural applications, edge rolling gradually forms the curve, allowing for smooth transitions and aesthetically pleasing finishes.

Bend Radius Charts, Calculators, and Tools

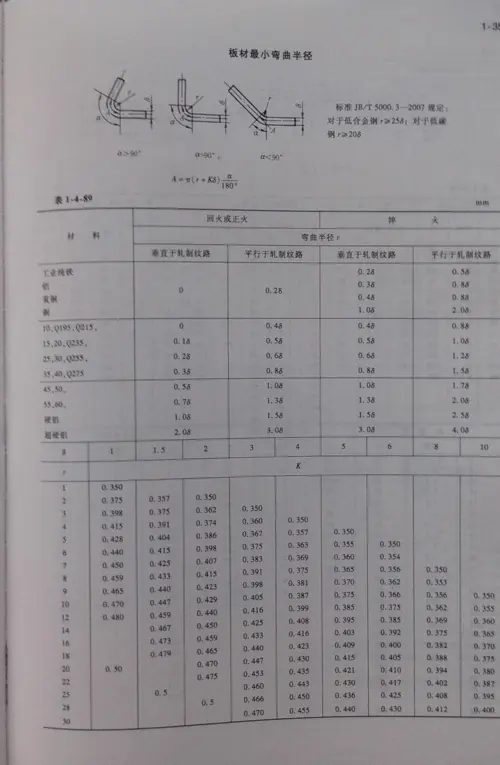

Utilizing Bend Radius Charts

Bend radius charts are commonly used to provide guidelines for the minimum bend radius based on material type and thickness. For instance, a chart might recommend a minimum bend radius of 0.5× the material thickness for steel or 0.8× for aluminum. However, these charts primarily focus on minimum values and do not fully address the considerations needed to determine the maximum bend radius.

Sheet Metal Bend Radius Calculators

Online tools like the Sheet Metal Bend Radius Calculator are useful for estimating bend allowances and setting up initial parameters. These calculators are typically geared toward ensuring that material integrity is maintained by focusing on minimum bend radii. When it comes to achieving a larger, maximum bend radius, it is crucial to consult with experienced fabrication partners who can provide tailored insights based on specific project needs.

Advanced Tools for Large Radii

To push the boundaries of what is achievable in sheet metal fabrication, advanced tools are essential:

-

Custom Dies for Press Brakes: Tailor-made dies can be engineered to meet specific large-radius requirements, enabling precise control over the bend curvature.

-

Adjustable Prototyping Tools: These tools allow for rapid prototyping in small batches, ensuring that the design meets the intended specifications before committing to full production.

-

CNC Press Brakes: With programmable controls, CNC press brakes deliver repeatability and precision, making them indispensable for projects requiring consistent large-radius bends.

-

Sheet Metal Rolling Techniques: Ideal for creating continuous, smooth curves, rolling techniques are often employed in the production of cylindrical pipes and enclosures.

How to Determine the Maximum Bend Radius in Practice

Consultation with Fabrication Experts

For projects where the maximum bend radius is a critical parameter, collaboration with seasoned fabrication professionals is vital. Experts at advanced sheet metal fabrication factories, such as Great Light, possess the experience and technical know-how to evaluate material behavior, design constraints, and tooling capabilities. This collaborative approach ensures that the proposed bend radius aligns with both design intent and manufacturing feasibility.

Prototype Testing and Leveraging Advanced Equipment

Before full-scale production, prototype testing serves as a critical step in validating the proposed large-radius bend. Testing with sample pieces allows engineers to assess any potential issues related to material stress, tool wear, or dimensional accuracy. Moreover, leveraging advanced equipment—such as 5-axis CNC machining services—provides the flexibility to refine and optimize the bend radius. These state-of-the-art systems offer enhanced precision and control, enabling the successful execution of complex geometries.

Conclusion: Flexibility Through Advanced Fabrication

The maximum sheet metal bend radius is not a fixed value but rather a dynamic parameter influenced by material properties, design requirements, and tooling limitations. Achieving the ideal balance between functionality and aesthetics requires a deep understanding of how different materials behave under stress and the technological capabilities of modern fabrication equipment. Advanced tools like custom dies, CNC press brakes, and 5-axis CNC machining services empower fabricators to push traditional limits, offering unparalleled flexibility for custom sheet metal fabrication.

Customize Your Sheet Metal Parts Today

If your project demands precise control over large-radius bends—whether for architectural elements, aerodynamic components, or intricate custom designs—explore advanced 5-axis CNC machining services and comprehensive sheet metal fabrication services. Collaborating with experienced partners, such as Great Light, ensures that your design vision is realized with the highest standards of quality, precision, and efficiency. Get in touch today to learn how custom sheet metal fabrication can elevate your next project.