Beyond Grinding: How Polishing Grinding is Revolutionizing Precision Gear Finishing

The relentless pursuit of efficiency, noise reduction, and longevity in powertrains demands microscopic precision. When it comes to finishing critical components like transmission gears, the choice between traditional grinding and the increasingly pivotal polishing grinding (PG) isn’t just about process—it’s about philosophy. It’s the difference between forceful correction and meticulous refinement. Understanding this distinction unlocks engineered surface perfection. Let’s dissect the core differences driving modern gear manufacturing.

1. The Fundamental Objective: Correction vs. Controlled Refinement

- Traditional Grinding: This is the workhorse, the sculptor. Its primary goal is macro-geometric correction. Think intricate tooth flank form deviations, profile lead errors, helix angle adjustments, and correcting distortions post-heat treat. It aggressively removes material (often targeting layers 0.1 mm or deeper) to enforce dimensional and geometric conformance to design specifications. It also addresses gross surface roughness but often unavoidably modifies the underlying material microstructure due to its thermal/mechanical intensity.

- Polishing Grinding: Here, the philosophy shifts to micro-geometric perfection. It assumes the macro-geometry established by prior operations (usually precision grinding) is fundamentally sound. PG operates with a laser focus: eliminate only the detrimental peaks of surface asperities (typically around 1 micron deep) while meticulously preserving the core roughness valley structures. This is crucial. Why? These micro-valleys are engineered reservoirs for lubrication, ensuring oil film adhesion critical for hydrodynamic lubrication elasto-hydrodynamic lubrication (EHL) regimes. PG guards the macro-geometry and the core surface texture integrity.

2. Abrasive Arsenal: Force vs. Finesse

- Traditional Grinding: Employs larger, aggressive abrasives (e.g., conventional grit sizes like 80 mesh with average particle diameters around 185 microns) bonded with stiff, rigid agents (vitrified bonds often dominate). This combination generates high cutting forces, essential for the heavy material removal and form correction it performs. Think emery cloth vs. sandpaper – it’s about cutting power.

- Polishing Grinding: Relies on ultra-fine abrasives (orders of magnitude finer, typically in the range of mesh sizes like 800 equivalent, with particles averaging single-digit microns – often 3-8 µm). Crucially, these abrasives are bonded using highly elastic polymer/resin bonds. This elasticity allows the abrasive grains to conform slightly to the micro-geometry, exerting a much softer, more controlled, and localized cutting force. It’s akin to precision buffing at a microscopic level, preventing plastic deformation beyond the targeted peaks.

3. The Surface Speaks Volumes: Depth, Texture, and Impact

- Traditional Grinding: Creates a smoother macro-surface by removing significant layers. However, this process unavoidably:

- Alters the near-surface microstructure (tempering, re-hardening zones, residual stress patterns), impacting fatigue properties – sometimes beneficially, sometimes detrimentally depending on control.

- Removes the entire population of asperities, both peaks and valleys, potentially reducing the effectiveness of natural oil retention pockets.

- Risk of thermal damage (burning) or micro-cracks exists if parameters aren’t tightly controlled.

- Polishing Grinding: Achieves controlled roughness improvement:

- Selective Peak Removal: Targets only the highest asperity tips, dramatically improving Ra/Rz values without destroying the functional valleys designed for lubrication.

- Preservation of Vital Micro-Channels: This ensures optimal oil film formation, pressure distribution, and anti-scuffing properties essential for quiet, high-load operation in transmissions.

- Mitigating Risks: Significantly reduces the overheating risk and eliminates the potential for "overworking" the surface that can lead to detrimental residual stress or microstructure changes. It protects the surface integrity achieved after quenching and tempering.

4. Process Synergy & Economic Efficiency

- Traditional Grinding: Often involves complex, multi-stage setups (roughing, semi-finishing, finishing) potentially on dedicated machines for each stage. This offers tremendous versatility and capacity for handling large stock allowances and significant geometric correction requirements across diverse gear sizes and materials. Process complexity and machine/tooling investment, however, can be substantial.

- Polishing Grinding: Is inherently designed as a high-value-add, complementary final step:

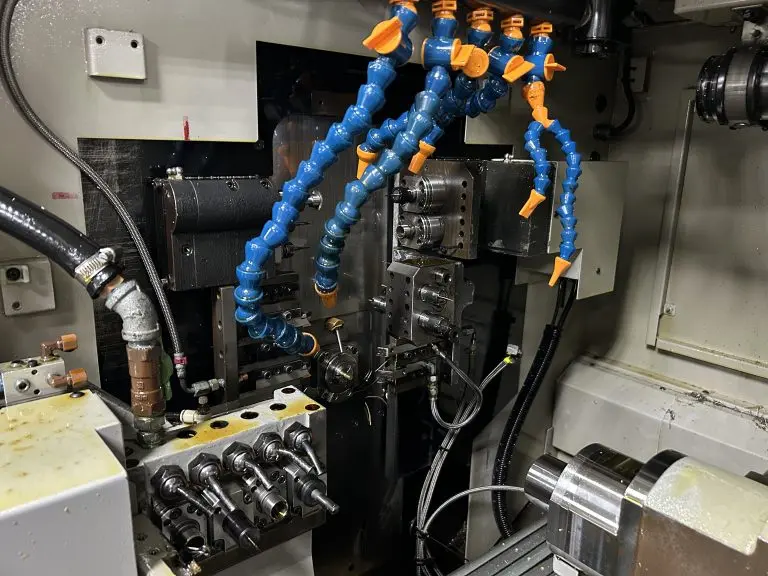

- Integrated Finishing: Crucially, PG integrates seamlessly as the last stage following precision grinding on Continuous Generating Gear Grinding (CGG) machines equipped with dual-purpose wheels. Here, the grinding section establishes geometry, and the integrated polishing section immediately delivers the final micro-finish – a "one-clamp" solution.

- Investment Leverage: While requiring specialized composite wheels, the real beauty is leveraging existing continuous gear grinding production lines. The incremental investment is remarkably low compared to adding a new machine, yet the performance gains are profound.

- ROI Focus: Its primary justification is surpassing quality targets and unlocking superior functional performance leading to quieter transmissions, reduced warranty costs, and improved fuel efficiency – yielding a high return on investment without adding significant process complexity.

5. Choosing the Right Tool for the Task

- Traditional Grinding is ideal when:

- Significant stock removal is required (post-forging, post-heat-treat distortion correction).

- Major geometric modifications to tooth flank form, lead, or involute profile are necessary.

- You need the brute force capability to handle diverse initial conditions.

- Polishing Grinding shines when:

- Macro-geometric accuracy is already achieved (via prior grinding).

- Ultimate micro-finish quality is paramount (lowest Ra/Rz, specific Rk parameters).

- Protecting and optimizing lubricant film adhesion is critical for noise reduction (NVH) and anti-scuffing performance (e.g., hypoid gears, automotive transmission gears, high-speed gears).

- You seek a cost-effective final finishing solution integrated into existing high-volume grinding lines.

- Preserving the exact microstructure and optimized residual stress state from prior processes is non-negotiable.

The Strategic Synthesis: Coexistence, Not Competition

Labeling polishing grinding and traditional grinding as competing technologies misses the mark. They are complementary forces within a sophisticated manufacturing strategy. Traditional grinding establishes the fundamental geometric foundation and removes bulk material with precision and power. Polishing grinding, acting as the meticulous final touch, elevates the micro-geometry to a state of near-perfect functionality. It’s the difference between precisely shaping a diamond (grinding) and achieving the final, flawless facets that release its brilliance (polishing grinding).

The most advanced gear manufacturers leverage this synergy. They employ robust traditional grinding processes to achieve dimensional perfection and then deploy integrated polishing grinding to unlock the crucial last microns of performance. This is where friction minimizes, noise signatures fade, fatigue life extends, and transmission efficiency reaches its peak potential. Polishing grinding isn’t just finishing; it’s the final, vital step in engineering surfaces that truly perform. It transforms precision into perfection, and perfection into dependable power.