The Complete Guide to Die Cast Aluminum Materials: Types, Applications, and Advantages

Introduction

In the world of manufacturing, die cast aluminum has emerged as a cornerstone material, revolutionizing how we approach product design and engineering. This comprehensive guide explores the various types of die cast aluminum materials, their unique properties, and their diverse applications across industries.

Understanding Die Cast Aluminum

Die cast aluminum represents a perfect blend of versatility and performance in modern manufacturing. As a lightweight yet robust material, it offers an impressive array of properties that make it invaluable across numerous applications. What sets aluminum apart is its unique combination of strength, durability, and processability, making it a preferred choice for engineers and designers worldwide.

Core Properties of Die Cast Aluminum

- Temperature Resistance: Highest operating temperature tolerance among die casting alloys

- Structural Integrity: Exceptional strength-to-weight ratio

- Corrosion Protection: Superior resistance to environmental factors

- Thermal Management: Outstanding heat dissipation capabilities

- Electromagnetic Properties: Excellent EMI and RFI shielding

- Sustainability: 100% recyclable material

- Finishing Characteristics: Highly suitable for various surface treatments

Revolutionary Hot Chamber Die Casting Technology

Breaking Traditional Boundaries

Historically, aluminum die casting was limited to cold chamber processes. However, recent technological breakthroughs have introduced hot chamber capabilities, marking a significant advancement in the industry. This innovation offers several key advantages:

Benefits of Hot Chamber Aluminum Die Casting

- Enhanced Production Efficiency

- Shortened production cycles

- Reduced operational costs

- Improved material flow

- Quality Improvements

- Minimized porosity

- Extended die life

- Better surface finish

- Consistent part quality

Primary Applications Across Industries

Automotive Sector

The automotive industry has embraced die cast aluminum for its ability to:

- Reduce vehicle weight

- Improve fuel efficiency

- Enhance structural integrity

- Provide excellent heat dissipation for engine components

Telecommunications and Computing

In the tech sector, die cast aluminum excels in:

- Network infrastructure equipment

- RF filter boxes

- Heat-dissipating housings

- Server components

Consumer Electronics

Die cast aluminum’s properties make it ideal for:

- Handheld device frames

- Electronic enclosures

- Protective casings

- Heat sinks

The Sustainability Advantage: Recycled Aluminum Die Casting

Environmental Impact

The die casting industry has made remarkable strides in sustainability, with over 95% of North American aluminum castings now produced from recycled materials. This achievement represents a significant environmental milestone and demonstrates the industry’s commitment to sustainable practices.

Economic Benefits

- 95% energy savings compared to primary aluminum production

- Reduced production costs

- Lower carbon footprint

- Maintained material quality

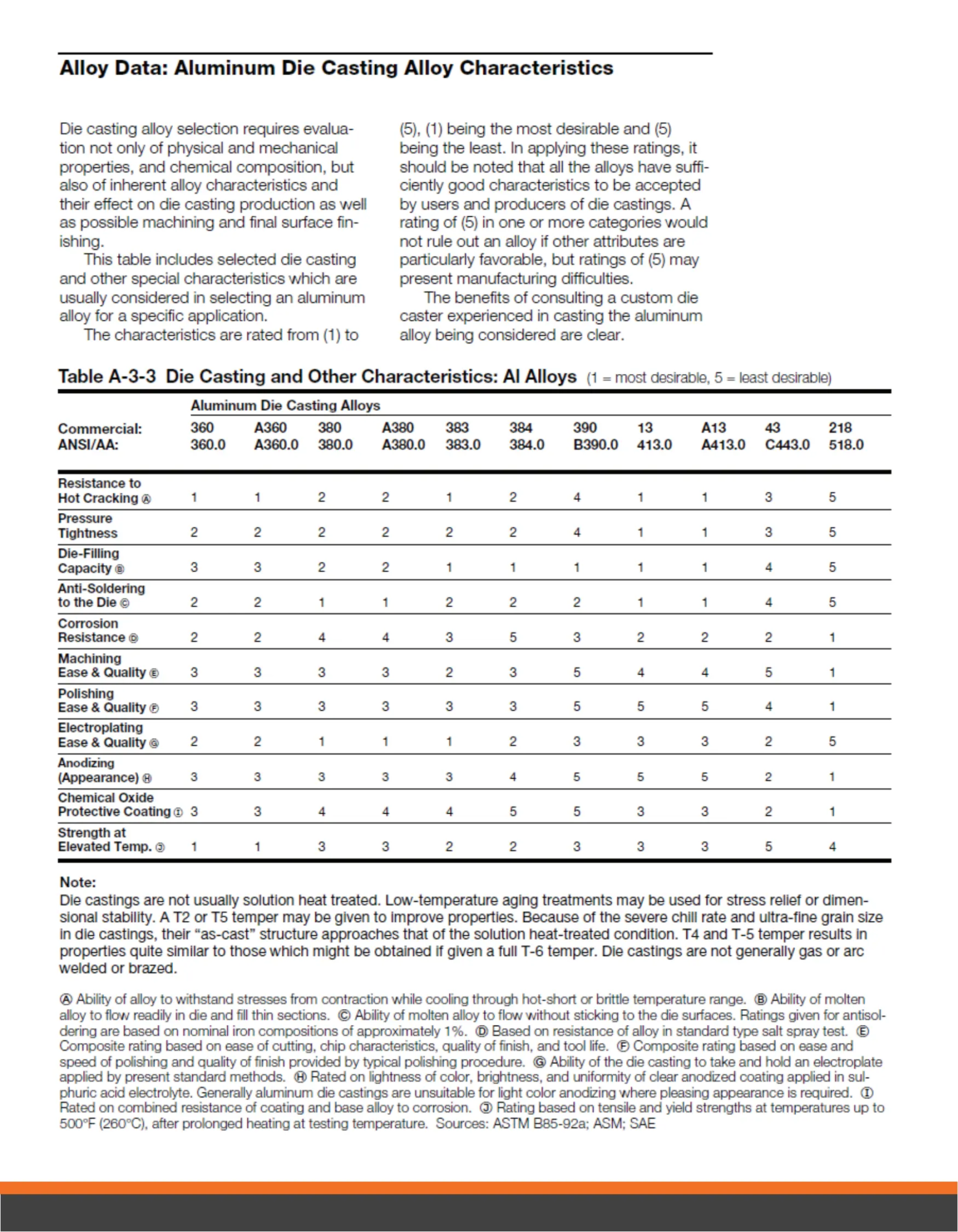

Common Aluminum Alloys and Their Applications

A380: The Industry Standard

Characteristics:

- Excellent fluidity

- Good mechanical properties

- Cost-effective

- Widely available

Best for: General-purpose applications requiring good strength and wear resistance

383 (ADC12): The Complex Solution

Characteristics:

- Superior castability

- Excellent for intricate designs

- Good pressure tightness

- Enhanced machinability

Best for: Complex components with detailed features

B390: The High-Performance Option

Characteristics:

- Superior hardness

- Exceptional wear resistance

- Good thermal conductivity

- High strength

Best for: Applications requiring wear resistance and strength

A413: The Pressure Master

Characteristics:

- Outstanding pressure resistance

- Excellent sealing properties

- Good corrosion resistance

- High ductility

Best for: Pressure-tight components and hydraulic applications

K-Alloy: The Environmental Defender

Characteristics:

- Enhanced corrosion resistance

- Superior environmental protection

- Good mechanical properties

- Excellent surface finish

Best for: Components exposed to harsh environments

A360: The Flow Champion

Characteristics:

- Exceptional pressure tightness

- Superior fluidity

- Good mechanical properties

- Excellent surface finish

Best for: Thin-walled components and pressure-tight applications

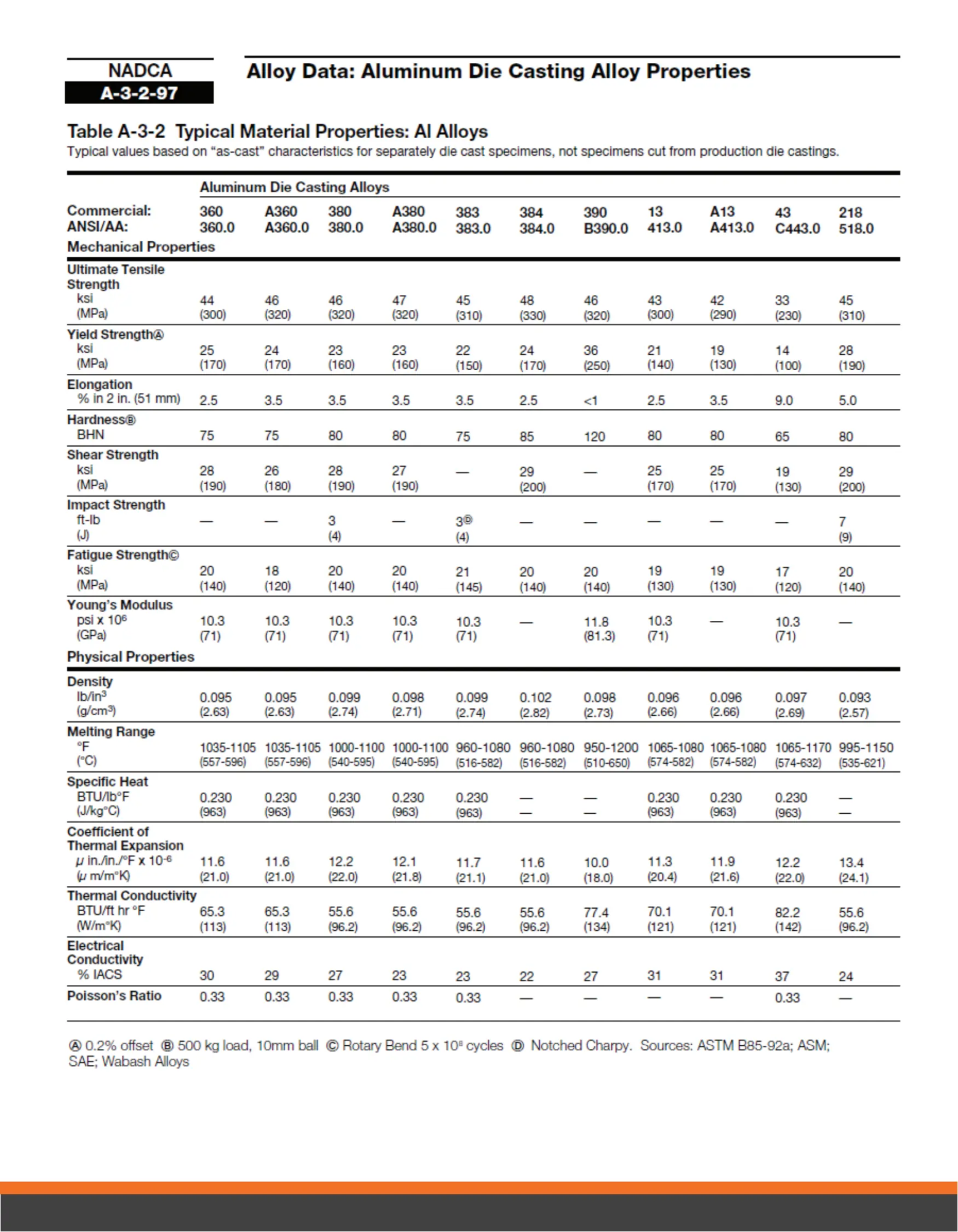

Mechanical Properties

|

Compare

|

Alloy | Density | Melting Point (Average +/- 50) | Thermal Conductivity | Coefficient of Thermal Expansion | Electrical Conductivity | Process |

|---|---|---|---|---|---|---|---|

|

g/cm3

|

°C

|

W / m K

|

µm/m°K

|

% IACS

|

|||

|

Aluminum Alloy A380

|

2.71

|

566

|

96

|

21.8

|

23.0

|

Cold Chamber Die Casting

|

|

|

Aluminum Alloy 383 (ADC12)

|

2.74

|

549

|

96

|

21.1

|

23.0

|

Cold Chamber Die Casting

|

|

|

B390

|

2.71

|

580

|

134

|

18.0

|

27.0

|

Cold Chamber Die Casting

|

|

|

A413

|

2.66

|

578

|

121

|

21.6

|

31.0

|

Cold Chamber Die Casting

|

|

|

413

|

2.66

|

578

|

113

|

20.4

|

31.0

|

Cold Chamber Die Casting

|

|

|

K-Alloy

|

2.63

|

680

|

113

|

–

|

32.0

|

Cold Chamber Die Casting

|

|

|

A360

|

2.63

|

577

|

113

|

21.0

|

29.0

|

Cold Chamber Die Casting

|

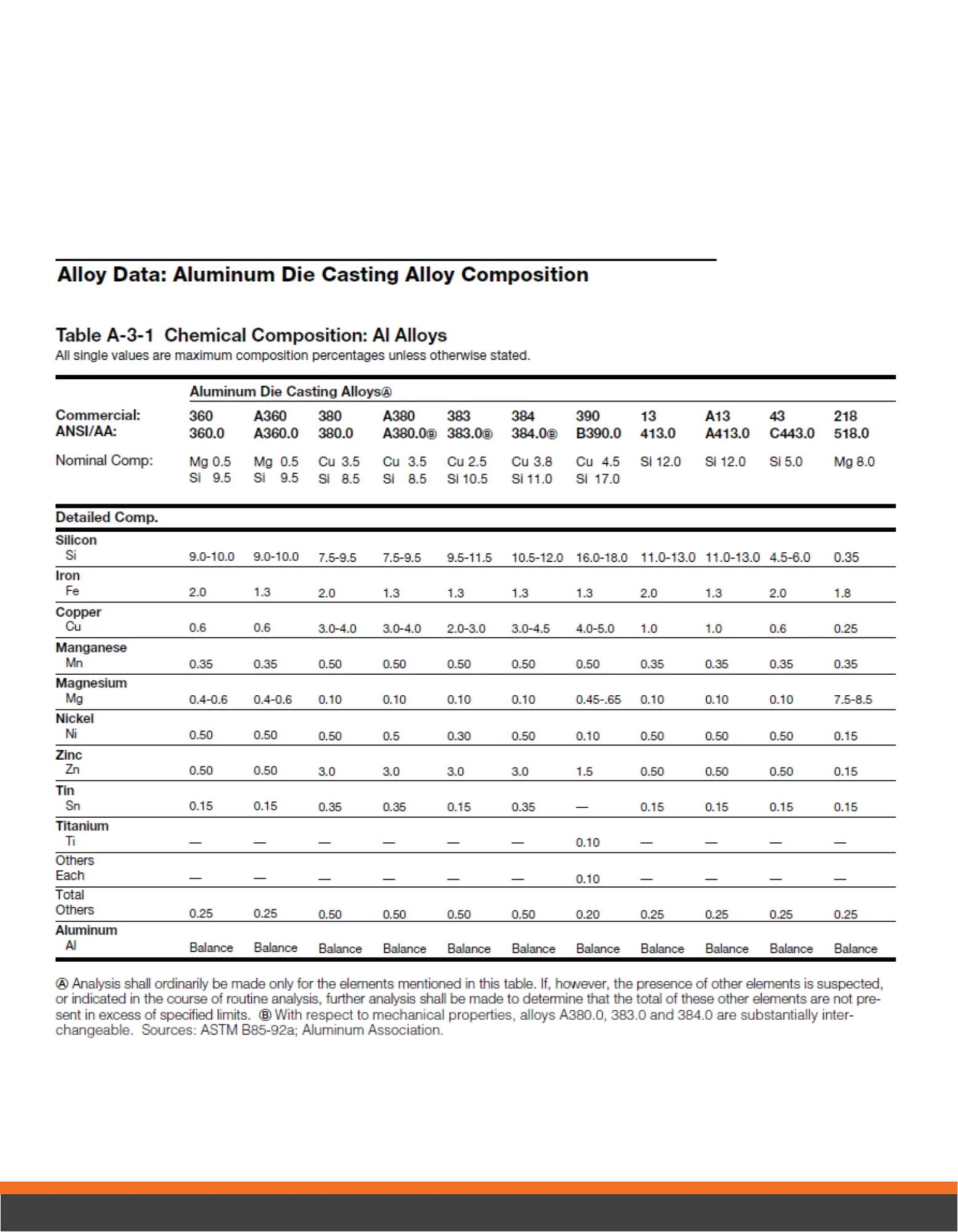

Composition

Emerging Technologies

- Advanced alloy development

- Improved recycling methods

- Enhanced processing techniques

- Smart manufacturing integration

Industry Predictions

- Increased use in electric vehicles

- Growth in aerospace applications

- Expansion in renewable energy sectors

- Innovation in consumer electronics

Conclusion

Die cast aluminum continues to evolve and adapt to meet the changing demands of modern manufacturing. Its versatility, combined with ongoing technological advancements and sustainable practices, ensures its position as a crucial material in the future of industrial production. Whether for automotive components, electronic housings, or complex machinery parts, die cast aluminum provides the perfect balance of performance, sustainability, and cost-effectiveness.