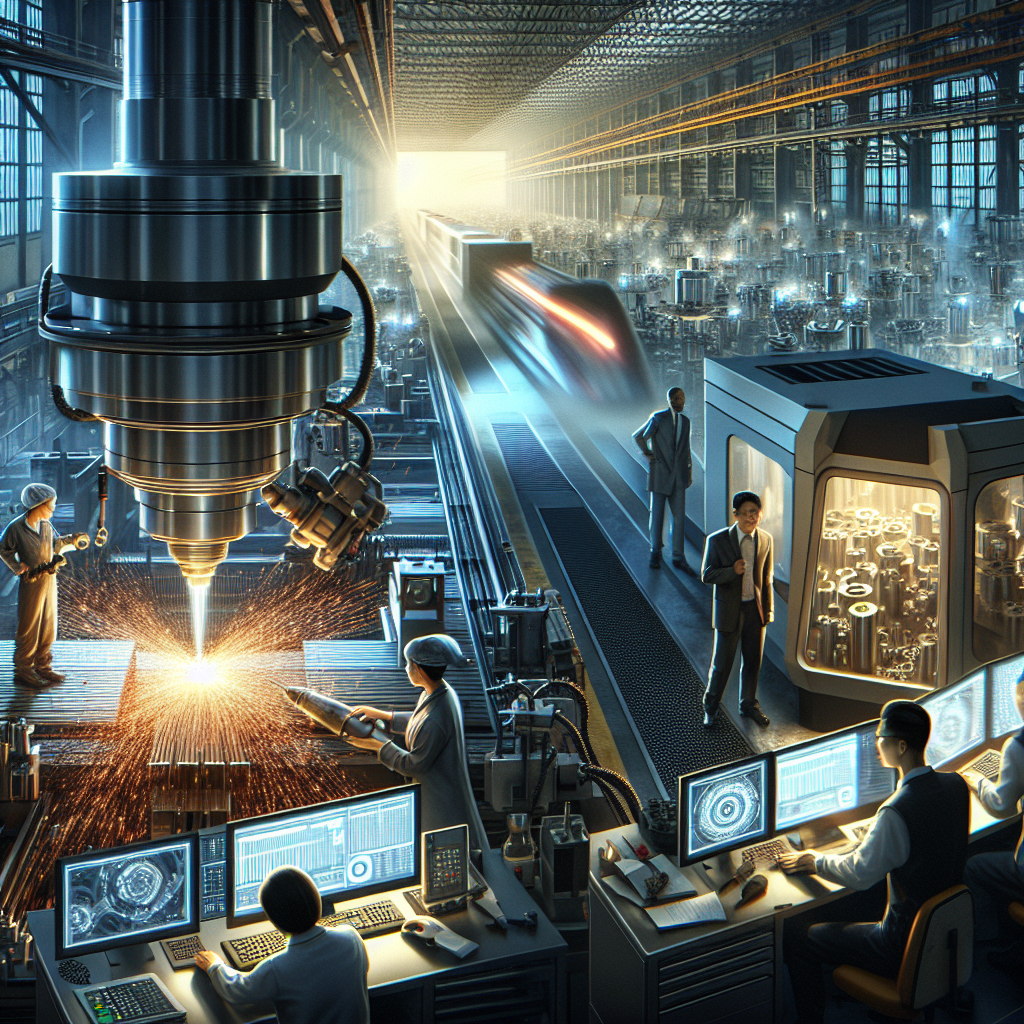

The manufacturing landscape has undergone significant transformation in recent years, and CNC (computer numerical control) machining plays a key role in this evolution. As one of the world’s manufacturing powers, China has become a leader in CNC machining technology. This article explores the rise of CNC machining in China, its impact on global manufacturing, and the innovations driving this phenomenon.

Learn about CNC machining

CNC machining refers to the process of using computers to control machine tools. These computer-controlled systems enable precise measurements, complex designs, and faster production cycles than traditional machining methods. CNC machines can process a variety of materials, including metals, plastics and composites, making them versatile tools in industries ranging from automotive to aerospace.

Main advantages of CNC machining

-

precision and accuracy: CNC machining allows for high precision, with tolerances often as low as a few microns. This is critical in an industry where small mistakes can lead to catastrophic failures.

-

efficiency and speed: Automated production processes significantly reduce the time required for manufacturing. CNC machines can run continuously, producing parts faster than manual methods.

-

Complexity and versatility: CNC machines can create complex geometries that are impossible to achieve with manual machining. They can be programmed to perform multiple operations in a single setup, reducing the need for additional processing and setup.

- Consistency and reproducibility: CNC machines can be programmed to produce consistent results across thousands of devices, ensuring high-quality output.

The historical context of CNC machining in China

China’s CNC machining journey began at the end of the 20th century. Initially, the country’s manufacturing industry was dominated by manual processing methods, which were labor-intensive and time-consuming. However, as China’s economy began to open up in the 1980s and 1990s, the need for higher-quality manufacturing processes necessitated a shift toward automation and precision.

Government support and policy initiatives

The Chinese government has recognized the importance of advanced manufacturing technologies, including CNC machining. measures such as "Made in China 2025" It aims to enhance the country’s manufacturing capabilities with a focus on automation, robotics and CNC technology. Government investment in R&D promotes innovation and enables companies to modernize machinery.

Technological innovation drives growth

The rise of CNC machining in China can be attributed to several technological innovations. Here are some of the key developments driving CNC growth in China:

Advanced software solutions

Modern CNC machine tools utilize advanced software to enable complex simulation and real-time monitoring. Software improvements enable manufacturers to optimize their processes, predict maintenance needs and improve overall efficiency.

The integration of artificial intelligence and the Internet of Things

The integration of artificial intelligence (AI) and the Internet of Things (IoT) with CNC machinery has revolutionized China’s manufacturing industry. These technologies enable predictive maintenance, facilitate remote monitoring and improve operational efficiency.

Development of multifunctional machines

The development of machines capable of performing multiple functions has minimized the need for additional machines. Machine tools that can turn, mill and drill in one setup can save time and space in manufacturing facilities.

The impact of CNC machining on major industries

The development of CNC machining in China has had a significant impact on various industries. Here are some of the industries being transformed by CNC technology:

1. Automobile industry

The automotive industry extensively integrates CNC machining to produce high-precision parts. CNC lathes, mills and milling machines are used to manufacture everything from engine parts to complex interior components. The rapid prototyping capabilities of CNC machines can also speed up design iterations, ensuring new models are brought to market faster.

2.Aerospace industry

Similar to automobiles, the aerospace industry requires high precision and quality standards. CNC machining is capable of manufacturing the complex geometries required for aircraft components, ensuring safety and efficiency. In recent years, Chinese aerospace companies have turned to CNC machining to increase production capabilities while maintaining strict quality control.

3. Medical device manufacturing

CNC machining is critical to the production of medical devices, where precision is critical. From surgical instruments to implants, the ability to produce complex shapes with high tolerances makes CNC machining indispensable in this field. China’s growing focus on healthcare and medical technology has spurred investment in CNC machining for these applications.

Challenges faced by CNC machining in China

Despite the rapid development and progress of CNC machining in China, there are still some challenges:

1. Skills gap

While CNC technology requires skilled operators, there is often a gap in the training and education of this part of the workforce. As the demand for CNC professionals continues to grow, ensuring workers are adequately trained is critical to maintaining production quality.

2. Competitive pressure

With the rapid growth of CNC machining capabilities, enterprises are not only facing competition from domestic enterprises, but also from international enterprises. This competitive landscape forces manufacturers to continuously innovate and improve efficiency.

3. Quality control

Maintaining consistent quality in mass-produced components is a challenge. As production scales increase, so does the need for effective quality control measures to ensure products meet regulatory standards and customer expectations.

The future of CNC machining in China

Looking to the future, the future of CNC machining in China is bright. As manufacturers continue to adopt advanced technologies, several trends are likely to shape the industry’s trajectory:

1. Continuous automation

Automation is expected to deepen its roots in CNC machining. Flexible systems that can adapt to changing demands will allow manufacturers to scale up or down production without causing major delays.

2. Sustainability

Sustainability is becoming increasingly important in manufacturing. CNC machining processes are often more material efficient than traditional methods, and the future lies in further reducing waste and emissions while increasing energy efficiency.

3. Global cooperation

As Chinese companies continue to innovate, partnerships and collaborations with international companies are likely to increase. Sharing knowledge and technology will enable China’s CNC market to further develop and enhance global competitiveness.

in conclusion

The rise of CNC machining in China marks a major turning point in the manufacturing landscape, not just in China but globally. A combination of government support, advanced technology, and a focus on quality and efficiency have made China a leader in this important field. As CNC machining continues to develop, it will play a vital role in shaping the future of manufacturing, providing unprecedented opportunities and challenges for industrialists around the world.

Frequently Asked Questions (FAQ)

Q1: What is CNC machining?

A1: CNC machining is a manufacturing process that uses computer-controlled machinery to produce precision parts. The process is known for its high precision and efficiency.

Q2: Why is CNC machining important in modern manufacturing?

A2: CNC machining can improve the accuracy, efficiency and repeatability of the manufacturing process. This is critical in industries where precise specifications and minimum tolerances are critical.

Q3: Which industries in China benefit from CNC machining?

A3: The main industries in China that benefit from CNC machining include automotive, aerospace, medical device manufacturing, electronics, and consumer goods.

Q4: What challenges does China’s CNC machining face?

A4: Challenges include skill gaps in the workforce, fierce competition, and the need for strict quality control measures to ensure stable production quality.

Q5: What is the future prospect of CNC machining in China?

A5: The future of CNC machining in China is likely to involve increased automation, a focus on sustainability, and potential global collaboration to enhance the industry’s technological advancements.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.