Reviving Precision: A Technical Deep Dive into Horizontal Broaching Machine Optimization

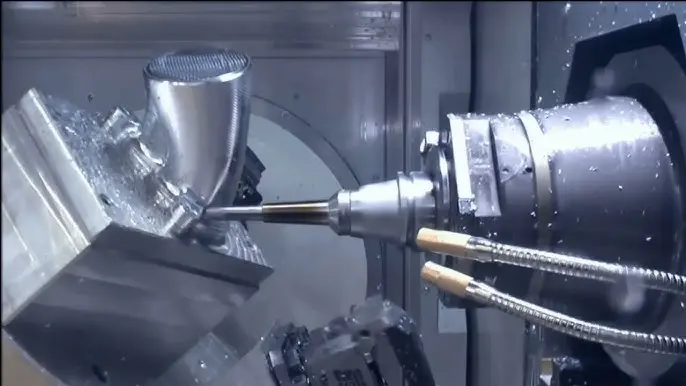

Horizontal broaching machines are the unsung heroes of precision manufacturing, essential for creating critical internal geometries like keyways and spline holes. Yet, subtle declines in broaching precision—manifesting as oversized dimensions, poor surface finishes, or out-of-tolerance profiles—can trigger costly rework, scrap piles, and accelerated tool/equipment wear. This guide delves into advanced, actionable strategies to diagnose, prevent, and reverse these issues, elevating your broaching operations from reactive troubleshooting to proactive excellence.

1. Core System Calibration: Rebuilding the Foundation

The bedrock of broaching accuracy lies in three interdependent subsystems. Compromise anywhere cascades into precision loss.

-

Guide Rail Rectification:

- Diagnosis: Over time, rail wear, contamination (swarf, grit), or thermal distortion introduces deviations in flatness and parallelism. Symptoms include inconsistent tool paths and chatter.

- Solution Protocol:

- Clean rails daily using non-abrasive solvents and lint-free cloths. Apply high-viscosity, anti-wear rail-specific lubricants.

- Measure alignment weekly with laser interferometers (for micron-level accuracy) or precision levels with 0.0001"/foot resolution.

- Correct deviations by adjusting hydrostatic support pads or replacing hardened-steel liners. Pro Tip: Install automated oil-scraping systems to combat debris accumulation.

-

Spindle Chuck & Workholding Integrity:

- Critical Failure Points: Worn collet tapers, degraded springs, or misaligned jaws induce radial runout and vibration during cutting.

- Remediation:

- Polish chuck seats using diamond lapping compounds. Verify concentricity with dial indicators (<0.0005" TIR).

- Replace tension springs prophylactically every 5,000 cycles. Use preload gauges to ensure uniform clamping force.

- Implement ultrasonic cleaning of taper interfaces to eliminate microscopic particulates causing "micro-wobble."

- Fixture Engineering:

- Beyond Pins: Upgrade from simple locating pins to kinematic mounts (3-2-1 principle) for stress-free, repeatable positioning. Mitigates distortion from over-constraint.

- Material Science: For high-load applications, design fixtures from cryogenically treated tool steel to delay wear. Validate with CMM checks on master components quarterly.

2. Broach Lifecycle Management: Beyond Sharpening

Broaches are not disposable tools; they require forensic-level monitoring.

-

Wear Pattern Analysis:

- Map flank wear (VBmax), notch wear, and chipping using USB digital microscopes (>200x magnification).

- Innovation: Embed micro RFID tags in broach shanks for automated usage tracking and predictive replacement scheduling.

-

Regrinding Cybersecurity:

- Use CNC-equipped cutter grinders with adaptive CAM software. Validate edge geometry via 3D optical comparators. Never regrind if edge depletion exceeds 20% of land width.

- Post-grind, apply TiAlN or CrN coatings to restore wear resistance.

- AI-Driven Storage:

- Store broaches vertically in humidity-controlled cabinets (<35% RH) with vibration-absorbing mounts. Integrate IoT sensors to alert on environmental breaches.

- Case Study: A Tier-1 gear manufacturer reduced broach replacement costs by 31% after deploying RFID-tagged tools linked to cloud-based analytics for usage optimization.

3. Process Physics: Mastering the Triad of Speed, Feed, and Material

Broaching isn’t brute force—it’s controlled fracture mechanics.

-

Speed vs. Heat Management:

- Formula: Calculate max speed (SFPM) using:

[ V_c = frac{(C_v times text{Material Hardness Factor})}{text{Broach Tooth Count}^{0.2}} ]

Where ( C_v ) = empirical constant based on tool coating. - Cutting Fluid Intelligence: For alloys (e.g., Inconel), switch from mineral oils to synthetic high-pressure coolants (HPC) with EP additives. Focus nozzles at chip-broach interfaces to suppress thermal softening.

- Formula: Calculate max speed (SFPM) using:

-

Feed Dynamics:

- Optimize chip per tooth (CPT) relative to material ductility:

- Ductile Materials (Aluminum): Higher CPT (0.002–0.005") prevents built-up edge.

- Brittle Materials (Cast Iron): Lower CPT (0.0005–0.001") combats edge crumbling.

- Smart Feedback: Instrument machines with dynamometers to monitor cutting forces in real-time. Auto-adjust feeds when forces trend >10% above baseline.

- Stress Engineering:

- Pre-treat distortion-prone parts using cryogenic stabilization (-196°C liquid N₂ cycles) to relieve residual stresses before broaching.

- Fixturing Innovation: For thin-wall components, design vacuum-assisted pallets with piezoelectric force sensors to detect deflection during cuts.

Conclusion: Precision as a System

Horizontal broaching precision isn’t sustained by luck—it’s engineered through system-level synergy. By fusing metrology-grade equipment calibration, intelligent broach stewardship, and physics-based process tuning, manufacturers transform "failure response" into "precision assurance." The goal: zero non-conformance, maximum uptime, and tool life extended beyond datasheet specs. In an age of tightening tolerances and exotic materials, this holistic discipline isn’t optional—it’s the competitive edge.

"A micron lost on the rails becomes a millimeter on the part. In broaching, precision compounds—both as loss and mastery."