Browse the UK used CNC central market: shrewd savings or expensive mistakes?

The UK manufacturing environment is dynamic and requires continuous innovation and investment. For emerging workshops, established SMEs are focusing on expansion, or niche manufacturers that need to increase capacity, and obtaining CNC machining centers represents a major capital expenditure. This is where the second-hand market becomes very attractive. A second-hand phone promises significantly lower prices and may provide access to features that are far beyond the budget of the new machine. But is it always wise? Absolutely – if You open your eyes and expertise to browse the market.

Why is the second-hand CNC center market booming in the UK

Attraction is undeniable:

- Large capital savings: The most obvious benefit. The cost of a high-quality 5-axis machining center may be 40-60% lower than its brand-new peers, which greatly reduces barriers to entry to advanced manufacturing capabilities. This can free up capital for investments in tools, materials or other business.

- Faster deployment: The lead time of the new CNC machine (especially the complex 5-axis model) can be extended to several months. Thoroughly reviewed second-hand phones are often shipped within weeks, minimizing downtime or faster expansion.

- Proven technology: Used machines have service history. After the initial bedding period, a well-maintained machine from a reputable OEM provides known reliability and performance. You won’t buy “v1.0” uncertainty.

- The edge of sustainability: Choosing a refurbished CNC center is essentially environmentally friendly. It extends the life cycle of machines, reduces the need for new resource extraction and manufacturing emissions, and avoids landfills. A green certificate is important.

- Visit higher levels: Often, the budget for new high-precision 3-axis machines may bring you an older, well-maintained 5-axis model. If your goal is 5-axis functionality, the second-hand market can achieve it.

Browse the UK Market: The main things to note when purchasing smartly

Careful trampling is not negotiable. Here is your purchase blueprint:

-

Define your needs accurately:

- part: What materials, dimensions, tolerances and surface treatments are required? This determines spindle power, torque, table size, travel, accuracy rating and coolant function.

- roll: The expected workload will affect the duty cycle requirements.

- ability: Is 3 axes sufficient? Do you need to use the 4-axis or 5-axis function at the same time? Is a large pallet pool essential? Don’t buy too much, but buy predictable growth.

- Shop constraints: Power supply (voltage, phase, ampere), floor space (including crane height/entry), compressed air, coolant drainage.

-

A reliable source is important:

- Well-known dealers: Looking for established UK experts with physical premises, known industry presence (e.g., membership of the Mechanical Auctioneers Association), detailed machine history and refurbishment features. They often provide guarantees and support.

- Direct from Level 1/Tier 2 suppliers: Sometimes, an OEM or large manufacturer will sell a refurbished front demo or low-time machine directly. Accumulated or bankrupted auctions can generate transactions, but they are more risky.

- Online Market: continue extreme warn. Ideal for research, but severely verified physical inspection and seller credibility. There is a scam.

-

Critical inspection and verification process (don’t skip this!):

- document: Service records, maintenance logs, installation manuals, electrical diagrams are gold dust. Digitally controlled backups are crucial.

- Physical condition: Beyond the light. Double check for signs of collision damage (misalignment, repaired castings, jagged edges). Check ball screws, linear method, spindle taper for wear/rating. Check the hydraulic/pneumatic cable for leaks. Listen to abnormal sounds during the test.

- Processing performance test: Performance testing is required under reduced load reductions related to expected work. This checks key indicators: positioning accuracy under load, achievable surface surface, thermal stability, rotational vibration/noise at speed, rigid strike performance.

- Control conditions: Is CNC control latest? Are spare parts still available? Is the interface available? Traditional controls can turn into expensive liabilities. Check the screen conditions, keyboard.

- Inspection method: Accurate measurements (via the accuracy level, preferred laser interferometer) geometric alignment, axes squared, rebound is essential to ensure continuous accuracy. "Cone" Testing is an excellent indicator of dynamic performance.

- Tool Changeers and ATC: Repeatedly test the smoothness, speed and reliability of the automatic tool changer – common fault points.

- Spindle time: Like car mileage, spindle rotation time is a key indicator of potential wear, especially on high-speed spindles.

- Understand the real cost:

- Renovation/Repair: Factors of refurbishing before installation (e.g., scraping replacement, screw rebuilding, spindle matte/replacement).

- Rigging and installation: Professional demolition, transportation, maneuver, reconnection and commissioning can be expensive, especially for large machining centers.

- Tools and labor: You need the right cat/BT/HSK holders, Vises, Fixed – This investment is important. Make sure the machine is compatible with the tool changer.

- Control upgrade/software: Companies like Greatlight offer one-time precise parts for five-axis machines, but upgrading old controls to get modern features can sometimes reach the price of new machine base models. Weigh carefully.

- Ongoing maintenance and parts: Availability and cost. Older machines may require professional technicians. Establish relationships with good CNC service providers, such as Greatlight, who understand remodeling complex machinery on UK store floors, even if they are primarily production partners like us.

5-axis precautions: Special circumstances

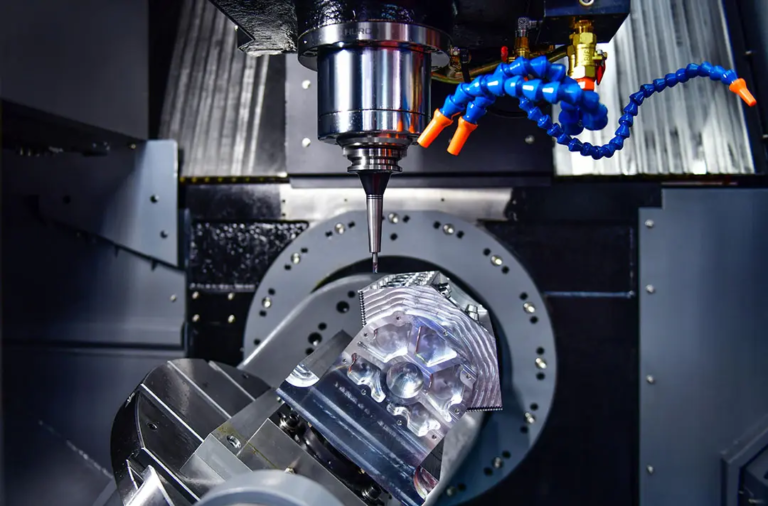

Purchasing a used 5-axis center will strengthen all the above points. The added complexity means more potential failure points (rotating/tilting heads, complex kinematics). Verify 5-axis accuracy, rebound and synchronization in the rotation axis are crucial. Performance testing under 5-axis motion using challenging tool paths is critical to discovering hidden geometric errors or controller compensation issues. Many dreamt 5-axis companies find that outsourcing complex geometry to dedicated experts, like Greatlight, actually provides greater predictability and cost-effectiveness until volume-scale large scales.

Gremight Option: Outsourcing Beats

While a well-accessed second-hand machine may be a strategic win, it requires a lot of in-house expertise, time and resources to acquire, refurbish, install, program and maintain. This is not everyone. This is the place for Greatlight Shines.

As a British expert Advanced five-axis CNC machining functionwe offer compelling alternatives:

- Zero capital expenditure: Eliminate purchase costs and related financial risks.

- Instant access to top technologies: Leverage our state-of-the-art 5-axis center and production technology.

- Complexity of solution: We solve your most challenging metallurgical problems (aluminum, steel, titanium, exotic alloys) through engineering expertise in baking in our services.

- Total solution: From raw materials to finished parts – including comprehensive post-treatment (heat treatment, plating, coating, assembly) – Greatlight offers seamless one-stop manufacturing.

- Scalability and speed: Respond quickly to demand fluctuations without machine downtime or delivery time concerns. Most materials can be processed quickly.

- Predictable cost: Benefit from clear, competitive pricing without hidden refurbishment or failure surprises.

- Unrivaled Eat: Take advantage of our experts Professional knowledge In precise processing, authoritative The process of training over the years, and Trustworthy Built on consistent quality and reliability. Google is increasingly paying attention to these signals, and the visibility of our solutions when designers seek it "Precision CNC Partners UK" or "5-axis machining expert."

Whether it’s prototype run or mass production, outsourcing to Greatlight means you can deliver on time with the support of engineering proprietary technology and crucially, you can make precision parts and free up your focus on your core business.

in conclusion

The second-hand CNC center market in the UK offers unparalleled opportunities for savvy manufacturers to significantly upgrade features or increase capacity at a fraction of the cost of new machines. Successfully defined laser-centric demands, from reputable outlets, detailed inspections and performance testing, and accurate range Total cost of ownershipincluding transportation and potential repairs.

For complex geometric shapes requiring 5-axis accuracy, the risk and resource requirements of the second-hand machine are significantly higher. This is a crucial critical moment: Pre-investment on a retro giant requires deep technical confidence and resources.

Before submitting, explore powerful alternatives: Outsourcing the precise CNC machining to Greatlime. It eliminates capital burden, deployment delays and reliability anxiety, providing immediate access to our advanced five-axis technology and end-to-end manufacturing excellence. Obtaining accuracy, speed, and confidence is usually a more predictable bottom line. Are you ready to see the Greatlight difference? Request a quote today. Contact our team for expert advice about your next project.

FAQ: Second-hand CNC Center in the UK

Question 1: What is the biggest risk when buying a second-hand CNC center?

A: Buy a machine with hidden major flaws (crash, huge wear of spindle screws/screws/ways) or the control system is outdated without having to fully understand the real cost of rectification. Enough inspections are not negotiable.

Q2: Can I get a warranty on a used CNC machine?

A: Reputable dealers usually offer limited warranty (for example, 90 days to 1 year). Purchase privately or through auction usually "As is, where" With zero warranty.

Q3: Is the CNC machining center “too old”?

A: There is no fixed age limit. It all depends on usage (spindle time), maintenance history, technical relevance and part availability. Often, machines over 15 to 20 years old face the challenge of controlling obsolete and critical mechanical parts. Reconstruction of middle age (7-12 years) is usually the best choice for valuable.

Question 4: What hidden expenses should I budget?

A: Key hiding costs include: rigging and installation; necessary renovations (spindle service, batting screw replacement, scraping methods); potential control software upgrades or calibration services; tools and labor; basic preparation; electrical upgrades; and ongoing maintenance/spare parts costs.

Q5: How important is it to see the machine running under load?

one: Crucial. Inadequate static visual inspection. Cut test pieces (ideally using similar parameters to your job) reveals spindle performance under load, shaft alignment issues, thermal stability, tool changer reliability, vibration and overall machine stiffness. Reject to buy without it.

Question 6: Are second-hand CNC machines available for financing?

A: Yes, a dedicated asset finance company offers a purchase option for lease or lease-purchased second-hand equipment, similar to new machinery financing, although terms may vary. Dealers often promote this.

Question 7: Why is it better to outsource complex parts than to buy used a machine?

A: Outsourcing eliminates huge upfront costs, hidden failure risks, renovation costs, lengthy setup/qualification times, maintenance overhead, and the need for professional programming/operation skills. Companies like Greatlight provide access to the latest technology, guaranteeing quality, scalability and focusing on delivery, making it an efficient solution for complex or volatile workloads. This is a strategic choice for agility.