Robotics Prototyping

Boost innovative product development and new product introduction for the robotics industry. Get your products to market faster with superior technology for specialized robotics components manufacturing.

Robotics Prototyping

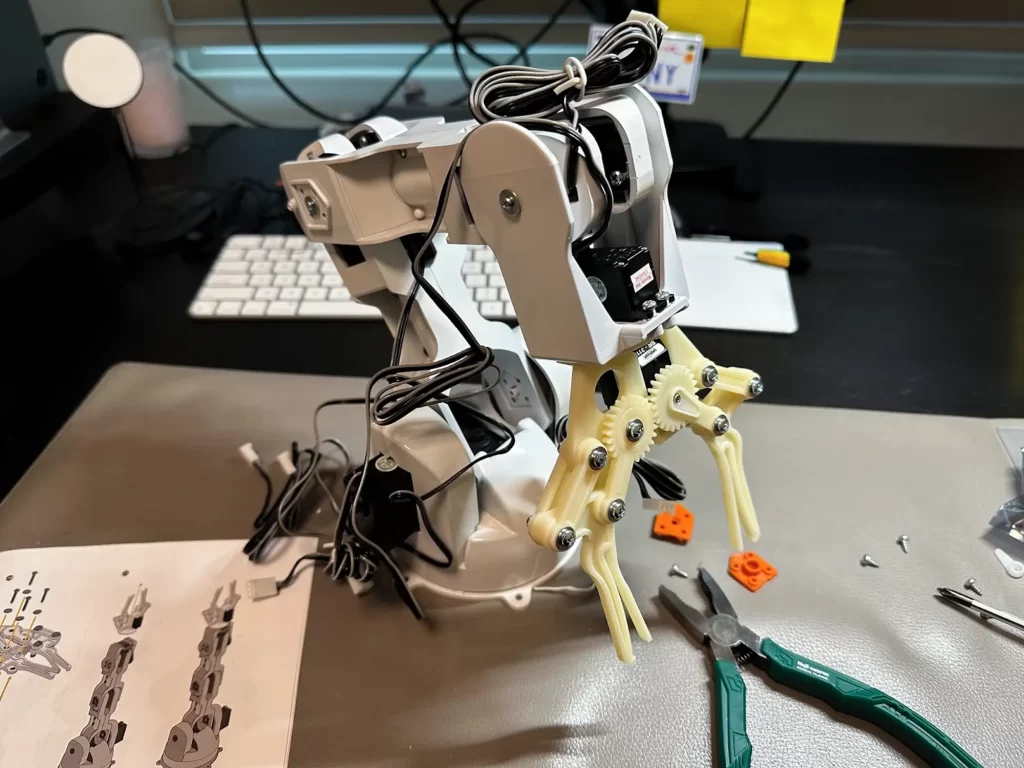

GL offers rapid prototyping and manufacturing solutions to satisfy the needs of the growing robotics sector. We offer reliable production services with quick turnaround times and a high-degree of quality inspection, so you can expect your parts to arrive quickly and in the best quality possible. Whether you need to prototype a full-fledged robotic systems or manufacture intricate parts, you can count on GL to deliver in a timely manner. Not only will we help you bring your prototype to the market quickly, we also guarantee high-quality and precise products at an affordable rate.

Processes & Techniques for Robotics Prototyping & Parts Manufacturing

- CNC Machining

- 3D Printing

- Clear Acrylic Machining and Polishing

- Aluminum machining

- Vacuum Casting

- RIM (Reaction Injection Molding)

Robotics Prototyping Applications

- Robot and Manipulator Prototyping and Design (based on task descriptions or other parameters)

- Rapid prototyping of robotic devices, sensors, actuators (including web-based manufacturing/ prototyping)

- Prototyping and simulations of Micro and nano systems.

- Automated manufacturing processes, systems, and techniques

- Prototyping robot-assisted medical devices and bio-medical engineering applications

- Prototyping for Information extraction

- Other emerging paradigms and technologies that are applicable to prototyping activities in Robotics and AI applications.

Few steps that should help you develop your next robotic prototype

- Ideas are cheap

As the internet developed massively, ideas are being shared faster than ever and more cheaply. The most costly part of an idea is now actually determining if the idea holds economic value.

By creating a robotic prototype, you can showcase your idea in a concrete form. Take the time to create a working prototype that correctly presents your idea. This means focusing your efforts not on making it look particularly good but on making a well rounded product, with all the required features.

- Don’t optimize for cost

You might be tempted to create the most elegant solution with the best internals and state of the art technologies. However this isn’t always desirable when creating your prototype, what you want is to develop your product rapidly and efficiently.

In some cases it might mean using the latest tech but most of the time it means using what you know will work and deliver results.

- Reconfigurable I/O

Building in robotics, you will use a lot of sensors and I/O devices, to save time, and not have to check what the required voltage is, how it has to be implemented etc. You should consider investing in a mechanism that enables you to quickly swap I/O devices and test them out.

Doing so will save you precious time and money.

- Design for Reuse

A prototype is supposed to be quickly developed in order to be improved. An efficient way to achieve this quick development is through reusability. Look at your previous projects, can you resume some software, or configurations, maybe designs or models ?

You should also keep in mind when designing that you might reuse what you’re currently doing, it’s always a good practice to keep notes or comments on what you’re doing to check back in the future if you pick it back up.

Robitcs Prototyping Cases

Ready to move? Get a quote now!

GL offers rapid prototyping and manufacturing solutions to satisfy the needs of the growing robotics sector.