As an important processing technology in sheet metal processing, welding is labor-intensive, has a harsh working environment and requires high skills. Therefore, automation of welding technology and new welding methods have always been the focus of technicians’ research. The key to achieving welding automation lies in the effective control of quality and efficiency, which requires solving problems such as centering the arc and weld beads, uniform gap between parts, weld penetration and weld distortion control.

With the rapid development of laser welding technology, this technology has been widely used in many fields. In the fields of household appliances, high-tech electronics, automobile manufacturing, high-speed train manufacturing, precision processing, etc., laser welding technology has demonstrated its unique advantages. The emergence of this technology not only changes the traditional welding method, but also greatly improves welding efficiency and precision. With the continuous development of science and technology, welding technology is also constantly improving. From the initial manual welding to today’s automated welding and new welding methods, welding technology has made a qualitative leap.

Features of laser welding

Laser welding uses a laser to couple a high-energy laser beam into an artificial optical fiber. After transmission, it is collimated into parallel light through a collimating mirror, then focused onto the part, bringing it together into an extremely high energy heat source. density, melting the material at the joint, then the liquid metal quickly. The welding method to form a high-quality weld after cooling is shown in Figure 1.

Figure 1 Laser welding

Easy to use and learn

The laser welding equipment has a simple structure, it is easy to learn the operation process, and it is easy to operate. The professional requirements of welding operators are not high, which can greatly reduce labor costs.

Micro-welding possible

The laser beam can get a very small spot after being focused and can be precisely positioned. It can be applied to assembly welding of micro and small parts in automated mass production.

Great flexibility

The laser welding machine can achieve welding at any angle, weld inaccessible parts, and can also weld various complex parts and large parts with irregular shapes, achieving welding at any angle and has high flexibility.

Good welding effect

The surface of the parts after laser welding is smooth, does not need to be polished, has no black edges, and no weld scars has any defects such as pores, cracks, undercuts or subsidence. the seam is more beautiful and smoother than ordinary second-hand protective welding and argon arc welding.

Strong safety performance

The high-security welding tip can only touch the switch when it comes into contact with metal, and the touch switch has body temperature detection. Special laser generators have safety requirements during operation. The operator should wear protective glasses for the laser generator to reduce eye damage.

High laser quality

Once the laser is focused, the power density is high. After the high-power low-order mode laser is focused, the focal spot diameter is small, which greatly promotes the development of automated thin plate welding.

Fast welding speed, large depth and small deformation

Laser welding has high power density. Small holes are formed in the metal material during the welding process. The laser energy is transmitted deep into the workpiece through the small holes with less side scattering, the material melting depth is greater during the laser beam scanning process. ; the speed is fast and the welding unit time is large area.

Manual welding is inexpensive

The heat input of laser welding is extremely small, the deformation after welding is very small, the welding slag is small, and the welding slag has no spatter. It can achieve a very beautiful welding effect on the surface. is less, which can reduce or eliminate subsequent polishing and leveling processes incurred.

Welding difficult-to-weld materials

Laser welding not only can weld a variety of different metal materials, but also can be used to weld titanium, nickel, zinc, copper, aluminum, chromium, niobium, gold, silver and other metals and their alloys, as well as steel, Kovar. Alloy and other materials. It can well meet the development and application of new materials for household appliances.

Suitable for welding thin plate parts without sprayed appearance

The laser welding machine has a high welding aspect ratio, a low energy ratio, a small heat-affected zone and a small amount of welding deformation. It is particularly suitable for welding parts with an unsprayed appearance made from thin, heat-sensitive plates. parts, which can reduce post-welding corrections and secondary processing.

Comparison of the advantages of laser welding

Laser welding can be divided into heat conduction welding and laser deep penetration welding according to the formation characteristics of the weld during welding. Heat conduction welding uses low laser power, the molten pool formation time is long and the penetration depth is shallow, and it is mainly used for welding small parts; deep penetration welding has high power density, the metal melts quickly in the laser radiation area, and the metal melts with strong vaporization, can obtain welds with greater penetration depth and weld width ratio can reach 10:1. The optical fiber transmission laser welding machine is equipped with an optional CCD camera monitoring system to facilitate observation and precise positioning; its welding point energy is evenly distributed and has the best point required for welding characteristics. It is suitable for various complex welds and spot welding; of various devices, complete welding and continuous welding of thin plates within 1mm.

The main factors affecting laser welding are beam characteristics, welding characteristics, shielding gas, material characteristics and welding performance. ⑴ Beam characteristics include laser, optical configuration, etc. ; ⑵ Welding characteristics include welding joint shape, weld distribution, assembly accuracy, welding process parameters, etc. ; ⑶ Shielding gas includes type, flow rate, shielding force type, etc. ; gas ; ⑷ Main material characteristics The wavelength and material of the laser This is related to the properties, temperature and surface conditions of the material. Most materials have higher absorption rates for short wavelength lasers. Materials have lower laser absorption rates at room temperature, and absorption rates increase sharply as temperature increases. (5) The welding properties of materials include thermal conductivity, thermal expansion coefficient, melting point, boiling point and other properties.

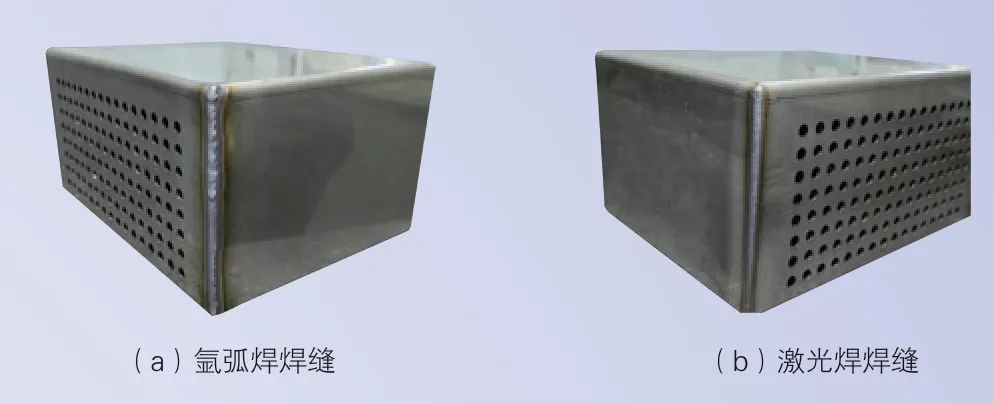

Compared with traditional manual argon arc welding or gas shielded welding, laser welding uses the latest generation of fiber lasers and is equipped with self-developed welding heads. It has the advantages of simple operation, beautiful welds, fast welding speed and no consumables. .It is used in stainless steel plates, iron. In terms of welding metal materials such as plates, galvanized plates, aluminum plates, etc., it can perfectly replace traditional argon arc welding, electric welding and other processes. The comparison of argon arc welding beads and laser welding beads of sheet metal parts is shown in Figure 2.

Figure 2 Comparison of Argon Arc Welding Beads and Laser Welding Beads

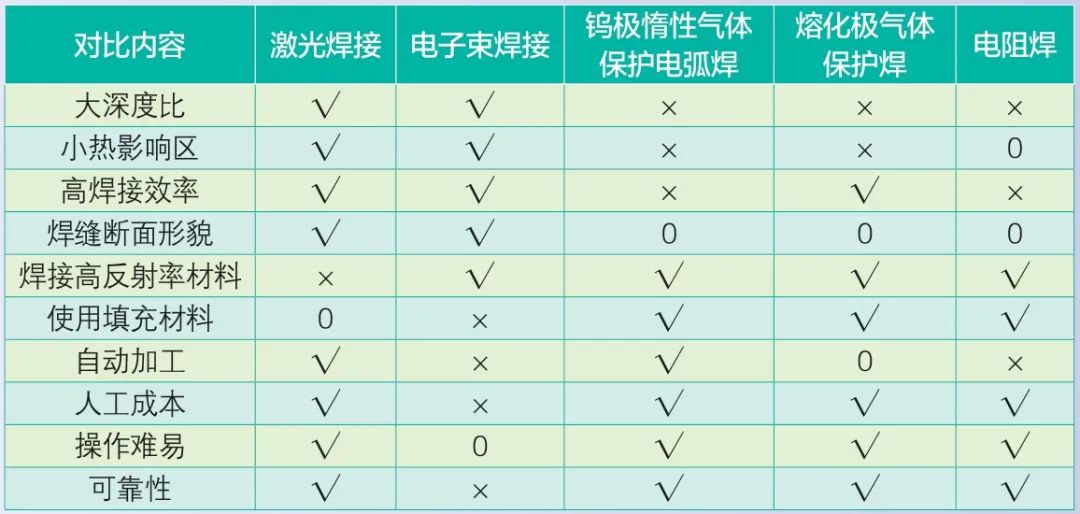

There are many commonly used welding methods for thin plates, such as laser welding, electron beam welding, argon arc welding, resistance welding, plasma arc welding , etc. Compared with other commonly used welding methods, laser welding has poor performance in the heat affected zone. , depth ratio and weld bead. It has great advantages in cross-sectional morphology, ease of operation, automatic processing and labor costs. The comparison between laser welding and other welding methods is shown in Table 1.

Table 1 Comparison between laser welding and other welding methods

Note: “√” indicates benefits; “×” indicates disadvantages; “0” indicates moderate.

Setting up the laser welding process

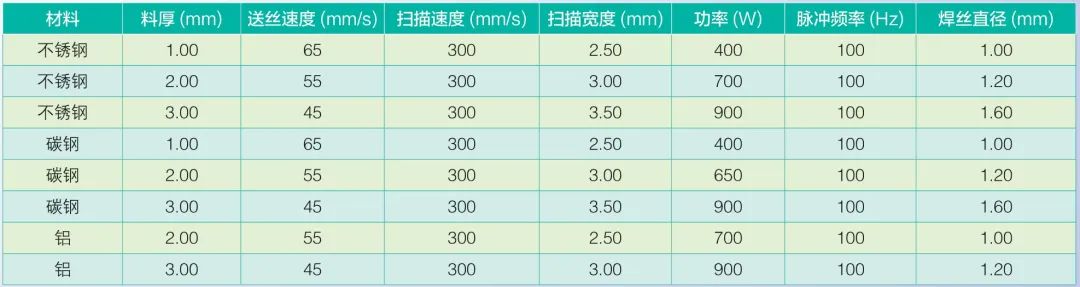

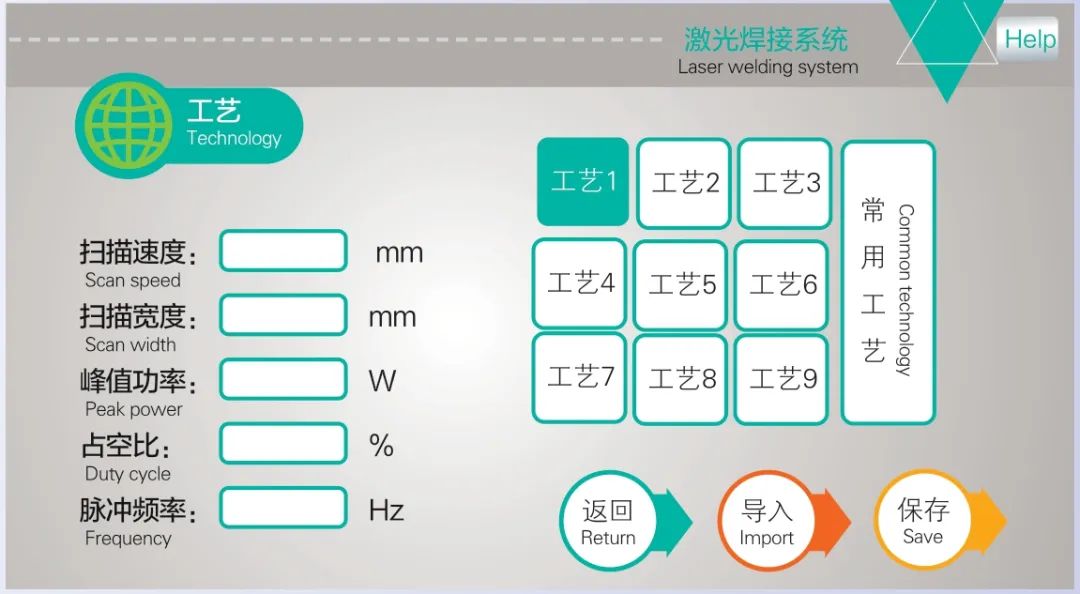

The key to laser welding equipment lies in setting and adjusting process parameters. Select different scan speeds, width, power and other values depending on the material thickness and workpiece material (duty cycle and pulse frequency are usually not necessary). be changed), as shown in Figure 3, the common process parameters are shown in Table 2.

Table 2 Common process parameters table

Figure 3 Process parameters of laser welding equipment

⑴ The process interface contains the parameters of the debugged process, which can be changed by clicking the box. After editing, click OK, then save it to the quick process, and click to import when using it ⑵ The scanning speed range is 2~; 6000mm/s and the scanning width range is 0-5mm. Scan speed is limited by scan width. The limit relationship is: 10 ≤ scanning speed / (scanning width × 2) ≤ 1000. If the limit is exceeded, it will automatically become the limit value. When the scan width is set to 0, there will be no scan (i.e. point light source) (most commonly used scan speed: 300 mm/s, width 2.5 mm (3) The maximum power must be less than or equal to ); laser power on the settings page; (4) Duty cycle range is 0-100 (default 100, usually no need to change); ⑸ Recommended pulse frequency range 5~5000Hz (default 2000, usually no need to change).

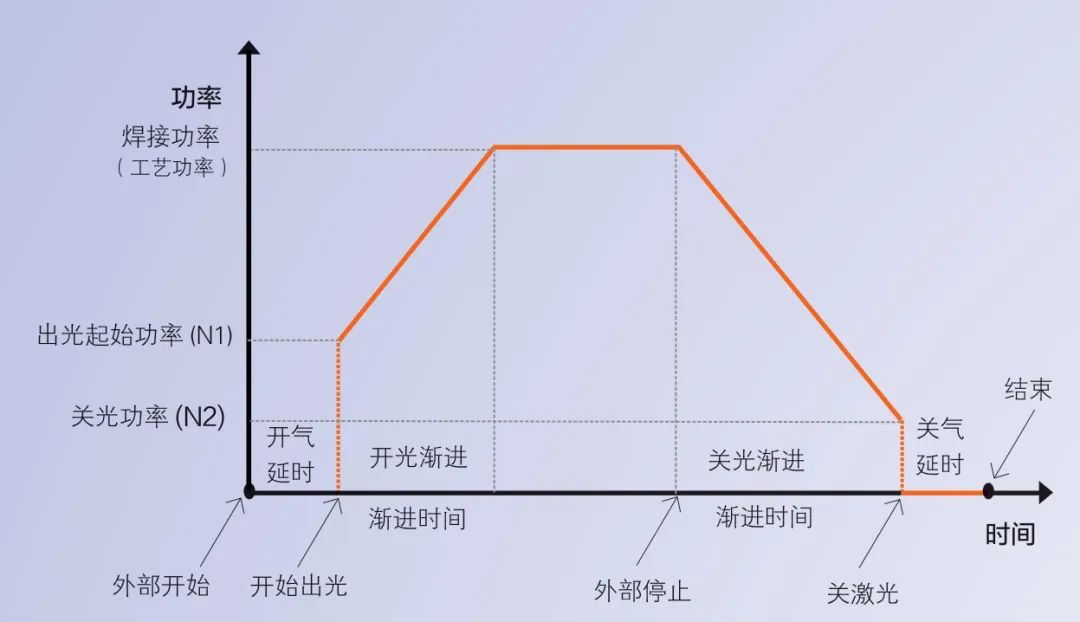

Different material thicknesses and materials have different welding powers. Laser power is the maximum power of the laser used. When the light is turned on, the processing power gradually increases from N1 to 100%; when the light is turned off, the processing power gradually increases from 100% to N2, as shown in Figure 4.

Figure 4 Schematic diagram of laser power

Application of laser welding equipment

The welding equipment in our commercial welding workshop includes: Panasonic YC-315TX argon arc welding machine, Panasonic YC-300WX argon arc welding machine, welding machine with protection Miller carbon dioxide, Jiashi WF-21 carbon dioxide protection welding machine, OTC carbon dioxide. Gas shielded welding machine and MIG welding machine, etc., as shown in Figures 5, 6 and 7.

Figure 5 YC-315TX Argon Arc Welding Machine

Figure 6 Jasic WF-21 welding machine with gas protection against carbon dioxide

Figure 7 OTC gas shielded welding machine with carbon dioxide

According to the production capacity of our single workshop, we can reduce the personnel investment of 3 people in welding and grinding operations, reduce the overall deformation by 20%, reduce the grinding workload by 30%, improve overall welding quality by 20%, and increase welding efficiency by 50%. After checking the quality of the product process and verifying the production operations, the laser welding machine can completely replace the traditional welding machine, and the effect is very obvious. As our company’s products involved in the fields of bus air conditioners, intelligent railway air conditioners and high-end home appliances began to emerge, in order to meet customers’ requirements for lightweight units and high-quality materials. range, only light and powerful welding can fully meet the requirements. welded connections of structural parts of these units. This is something that traditional welding cannot achieve.

Conclusion

Welding technology is an important cornerstone for my country to become a major manufacturing country. Today, almost all fields, such as machine manufacturing, petrochemical industry, transportation, energy, metallurgy, electronics, aerospace, etc., are inseparable from supporting technology. welding. The new generation of welding technologies, represented by electron beam welding and laser welding, are increasingly used. Considering the factors of environmental protection and operating costs, laser welding has many advantages such as high power density, no electrode pollution, no contact, low machine loss and tool, is not affected by magnetic fields and can accurately align welds. Therefore, laser welding is the development trend of future welding, which also requires enterprise technicians to put forward better and higher application-level requirements to encourage laser welding machine enterprises to move forward together .

Text/Lu Changshui, Tan Xiaoyu, Huang Qicun, Wang Haosong·Zhuhai Gree Electric Co., Ltd. Sheet metal spraying branch factory

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.