Protolabs Vs Xometry: A Comprehensive Comparison and Why Great Light Shines for 5-Axis CNC Machining

When it comes to manufacturing precision parts, selecting the right service provider for 5-axis CNC machining can make or break your project. Industry leaders like Protolabs and Xometry often dominate the conversation, but other players, such as Fictiv and Great Light, bring unique strengths to the table. This in-depth blog post compares these four companies, focusing on their capabilities, advantages, and processing sizes for 5-axis CNC machining. By the end, you’ll see why Great Light emerges as a standout option for custom metal parts manufacturing, especially for those seeking online CNC machining services.

What is 5-Axis CNC Machining?

Before we dive into the comparison, let’s clarify what 5-axis CNC machining entails. Unlike traditional 3-axis machining, which operates along the X, Y, and Z axes, 5-axis machining introduces two additional rotational axes (A and B). This advanced technology allows for intricate cuts and complex geometries in a single setup, reducing production time and enhancing precision. It’s a game-changer for industries like aerospace, automotive, and medical, where 5-axis CNC machining for metal parts is often a necessity.

Comparing the Contenders: Protolabs, Xometry, Fictiv, and Great Light

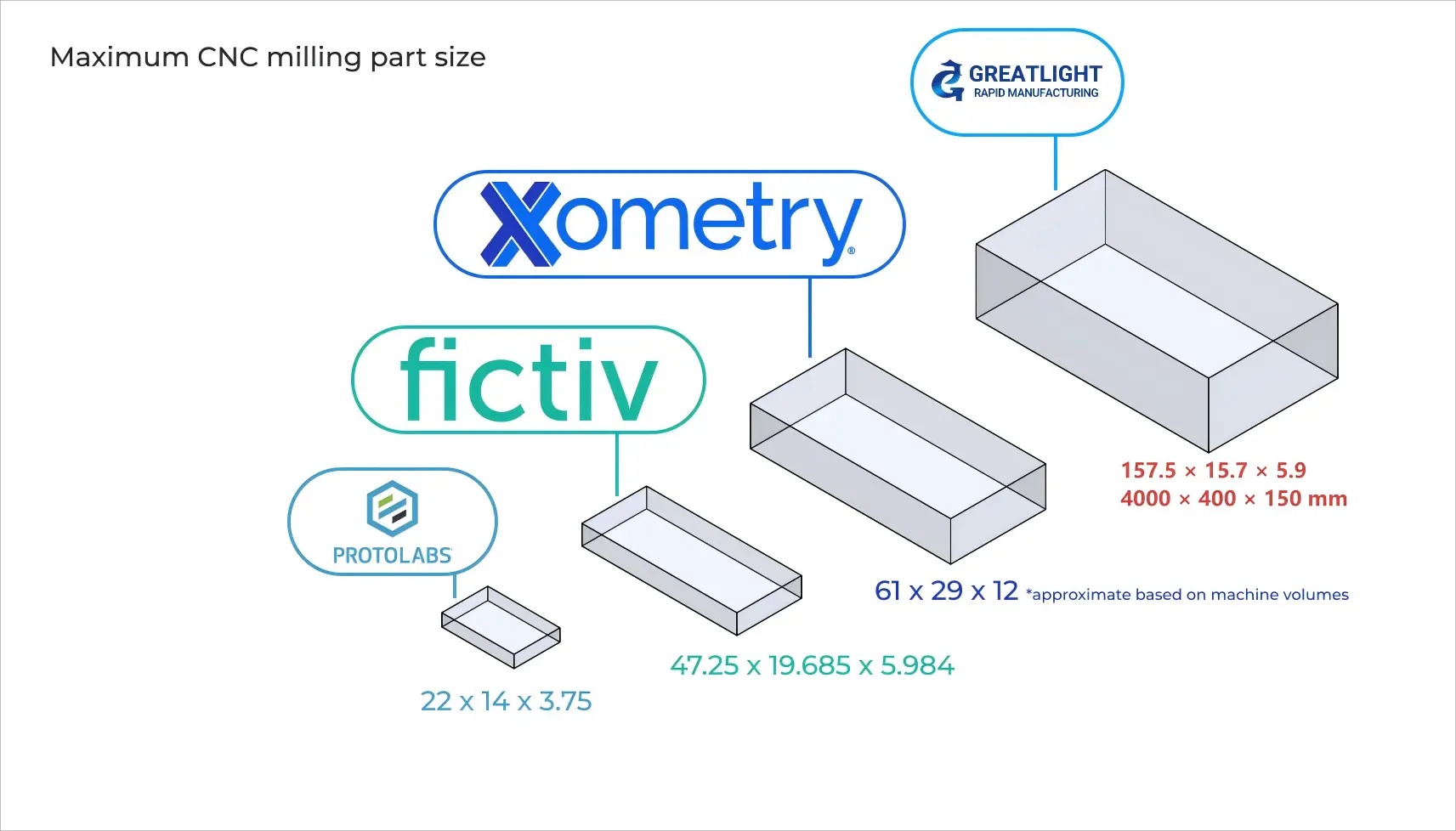

Each of these service providers offers distinct advantages, making them suitable for different project needs. Below, we break down their maximum processing sizes and core strengths to help you decide which aligns best with your requirements.

Protolabs: Speed and Precision for Small Parts

Protolabs is a pioneer in rapid prototyping, known for its ability to deliver high-quality parts quickly.

Maximum Processing Size

- Dimensions: 22 × 14 × 3.75 inches

- Remarks: Protolabs excels at processing small parts, making it ideal for compact components like those used in medical devices or electronics.

Core Advantages

- Ultra-High Precision: With tolerances as tight as ±0.025 mm, Protolabs is a leader in precision manufacturing.

- Speed: Specializing in rapid prototyping and small-batch production, they can deliver parts in as little as 1-3 days.

- Automated Quoting: Their online platform generates instant quotes after uploading CAD files, streamlining the ordering process.

Why Choose Protolabs?

If your project involves small, intricate parts requiring tight tolerances—think optical components or microfluidic chips—Protolabs is a strong contender in the “Protolabs Vs Xometry” debate.

Xometry: Versatility and Scale

Xometry stands out for its expansive network and ability to handle diverse manufacturing needs.

Maximum Processing Size

- Dimensions: Approximately 1550 × 737 × 305 mm (61 × 29 × 12 inches)

- Remarks: Xometry’s larger capacity suits medium to large parts, such as automotive chassis or aviation brackets.

Core Advantages

- Global Network: Xometry connects you with a worldwide pool of manufacturers, ensuring flexibility and scalability.

- Material Variety: They offer an extensive range of materials, including aerospace-grade alloys and engineering plastics.

- Quick Turnaround: Xometry excels at urgent, high-volume orders with reliable delivery timelines.

Why Choose Xometry?

For projects requiring complex structures or specific certifications like AS9100, Xometry’s versatility makes it a key player when comparing “Protolabs Vs Xometry.”

Fictiv: Digital Efficiency for Small to Medium Parts

Fictiv leverages a digital-first approach to simplify manufacturing and collaboration.

Maximum Processing Size

- Dimensions: Approximately 47 × 19 × 12 inches

- Remarks: Fictiv is well-suited for small to medium-sized parts, balancing capability and cost.

Core Advantages

- Digital Tools: Their online platform enhances project management and team collaboration.

- Cost-Effectiveness: Fictiv offers competitive pricing for parts under 1m³.

- Design Feedback: Real-time design for manufacturability (DFM) support helps optimize your designs.

Why Choose Fictiv?

If you’re working on small to medium parts and value digital tools and design support, Fictiv is a solid option.

Great Light: The Pinnacle of 5-Axis CNC Machining

Great Light sets itself apart with its specialized focus on 5-axis CNC machining and exceptional capabilities.

Maximum Processing Size

- Dimensions: 4000 × 400 × 150 mm (157.5 × 15.7 × 5.9 inches)

- Remarks: Great Light offers the largest processing size, perfect for oversized, complex components.

Core Advantages

- Unmatched Precision: Tolerances as tight as ±0.001 mm make Great Light a leader in high-precision machining.

- Rapid Delivery: They can produce small to medium parts in as little as 72 hours.

- Cost Efficiency: Great Light provides the lowest production costs among the four, ideal for budget-conscious projects.

- Material Flexibility: Like Xometry, they support a wide range of materials, including aerospace-grade alloys.

- Certifications: With credentials like ISO 9001:2015, ISO 13485:2016, ISO 27001:2022, and IATF 16949:2016, Great Light serves industries such as aviation, automotive, and medical with proven expertise.

- One-Stop Shop: In-house production covers machining, post-processing, and finishing, ensuring quality and consistency.

Why Choose Great Light?

For emergency prototyping, large-scale projects, or ultra-precise custom metal parts manufacturing, Great Light’s 5-axis CNC machining capabilities are unmatched.

Head-to-Head: Protolabs Vs Xometry Vs Fictiv Vs Great Light

To make an informed decision, let’s compare these providers across key metrics:

| Feature | Protolabs | Xometry | Fictiv | Great Light |

|---|---|---|---|---|

| Max Size | 22 × 14 × 3.75 in | ≈61 × 29 × 12 in | ≈47 × 19 × 12 in | 157.5 × 15.7 × 5.9 in |

| Precision | ±0.025 mm | Varies by partner | Varies by partner | ±0.001 mm |

| Speed | 1-3 days | Varies, often 1-3 days | Varies | As fast as 72 hours |

| Cost | Higher for volume | Competitive for prototypes | Cost-effective for small/medium | Lowest overall |

| Certifications | ISO 9001 | Partner-dependent | Partner-dependent | ISO 9001, 13485, 27001, IATF 16949 |

Key Takeaways

- Protolabs: Best for small, high-precision parts with quick turnaround.

- Xometry: Ideal for larger parts and material diversity via a global network.

- Fictiv: Great for digital collaboration and cost-effective small to medium parts.

- Great Light: Excels in precision, size, speed, and cost, especially for 5-axis CNC machining for metal parts.

Why Great Light Stands Out for 5-Axis CNC Machining

While Protolabs, Xometry, and Fictiv each have their merits, Great Light offers a compelling edge for those seeking online CNC machining services. Here’s why:

Superior Precision and Size

With tolerances of ±0.001 mm and a maximum processing size of 4000 mm in length, Great Light tackles both intricate and oversized projects with ease. This makes them the go-to for complex aerospace components or large automotive parts.

Lightning-Fast Delivery

Need parts in a hurry? Great Light’s ability to deliver within 72 hours ensures your project stays on track, even under tight deadlines.

Cost-Effective Excellence

By managing production in-house, Great Light keeps costs low without compromising quality—perfect for prototypes or full-scale production runs.

Industry-Leading Certifications

Their extensive certifications (ISO 9001, ISO 13485, ISO 27001, IATF 16949) and expertise across aviation, medical, robotics, and more instill confidence in their reliability.

Comprehensive Service

From machining to finishing, Great Light handles it all, providing a seamless experience for custom metal parts manufacturing.

Whether you’re prototyping a medical device or producing large aerospace components, Great Light’s 5-axis CNC machining capabilities deliver unmatched value.

Conclusion: Making the Right Choice

In the “Protolabs Vs Xometry” showdown, both companies shine in their respective niches—Protolabs for small, precise parts and Xometry for versatility and scale. Fictiv adds digital efficiency to the mix, but Great Light takes the crown for 5-axis CNC machining. With its blend of precision, speed, affordability, and expertise, Great Light is the ultimate choice for online customization of metal parts. Ready to elevate your next project? Explore Great Light 5 Axis CNC Machining today and unlock the best in manufacturing excellence.