Medical Devices Rapid Prototyping

We offer reliable rapid prototyping and rapid manufacturing solutions crafted to suit the needs of the medical device industry. Regardless of our project load, our customers can rest assured that we will deliver high quality, precision products on time and at affordable rates.

- Production-grade products

- ISO 9001:2015 certified

- 24/7 engineering support

Why manufacture

medical device parts with GreatLight?

ISO certified

GreatLight Rapid Prototyping (GL) is an ISO9001-2015 certified manufacturer that can guarantee top quality parts in an industry that demands rigorous consistency and quality control.

Huge production capacity

We can fulfill orders of virtually any size, from one-off engine part prototypes to full production of injection molded headlamp covers.

Range of services

Equal parts machine shop and digital manufacturing specialist, we offer a range of manufacturing technologies and services, from CNC machining to 3D printing.

Short lead time

Our extensive facilities and partner network allows us to fulfill orders quickly, no matter the quantity or complexity.

Skilled and experienced

We have been manufacturing automotive parts for over a decade and our skilled engineers know how to get the best outcomes from your designs.

Easy quotation system

Our engineers will review your designs immediately to provide a fast and accurate quotation for the project.

Our team is dedicated to providing you with excellent, efficient, and economical rapid prototyping and manufacturing solutions. Our experience, expert team, and cutting-edge equipment allow us to bring your ideas from design to market.

To learn more about our capabilities or help with prototyping your next medical device, contact us, or request a quote today.

Medical Devices Rapid Prototyping

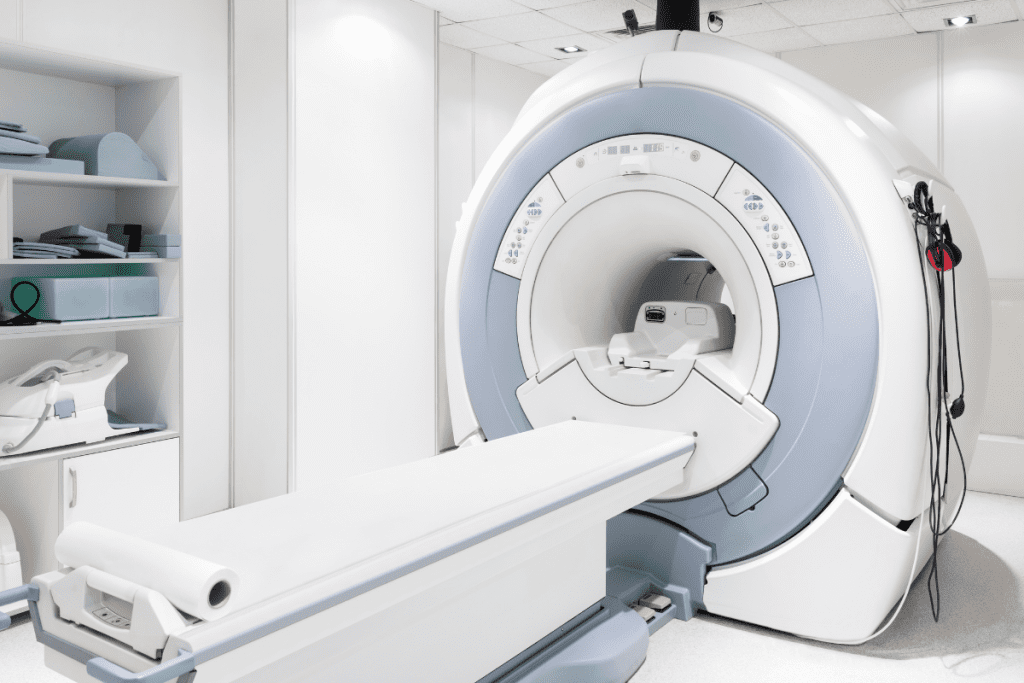

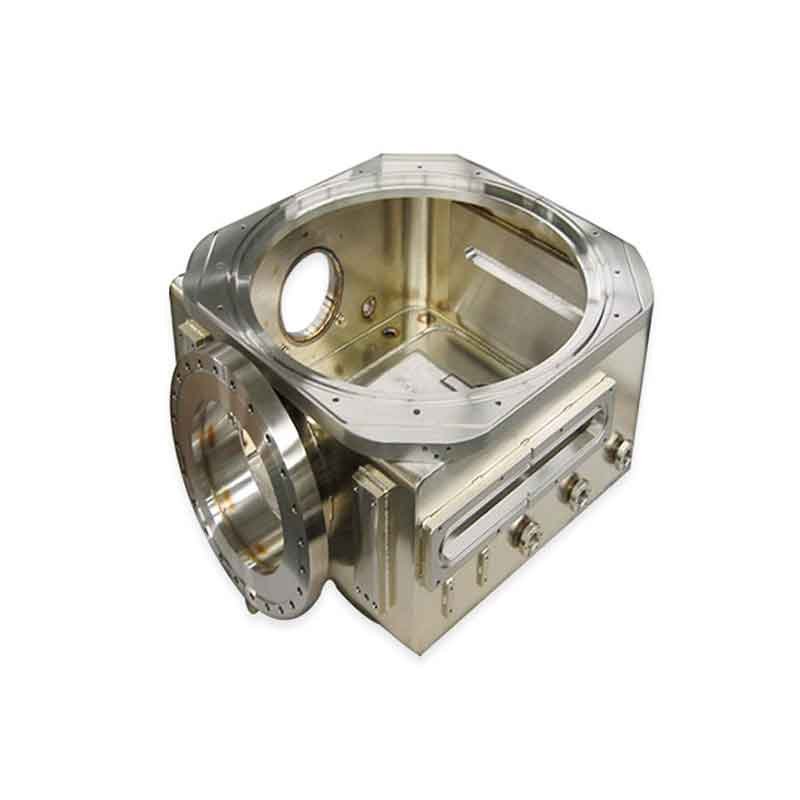

With the improvement of medical devices and technology, pharmaceutical equipment updates and upgrades as well. Once the appearance and model designed, you have to make rapid prototypings to verify the feasibility of your idea. The main difficulty in medical industry is the materials hard to machine, complex shapes and the extremely high demand for precision. GL is equipped with 5-axis, 4-axis and 3-axis CNC machining centers which can meet your demand perfectly.

We offer reliable rapid prototyping and rapid manufacturing solutions crafted to suit the needs of the medical device industry. Regardless of our project load, our customers can rest assured that we will deliver high quality, precision products on time and at affordable rates.

What kind of medical device parts can we make?

Gerenally speaking, the plastics which can be used for production injection molding, they can be molded by prototype mold as well. Here are the most commonly molded plastics. If the material is not listed, please contact our team for more information.

Below are some of the types of automotive parts we can manufacture for you:

- Prototypes

- Anatomical models

- Replacement parts

- Surgical instruments

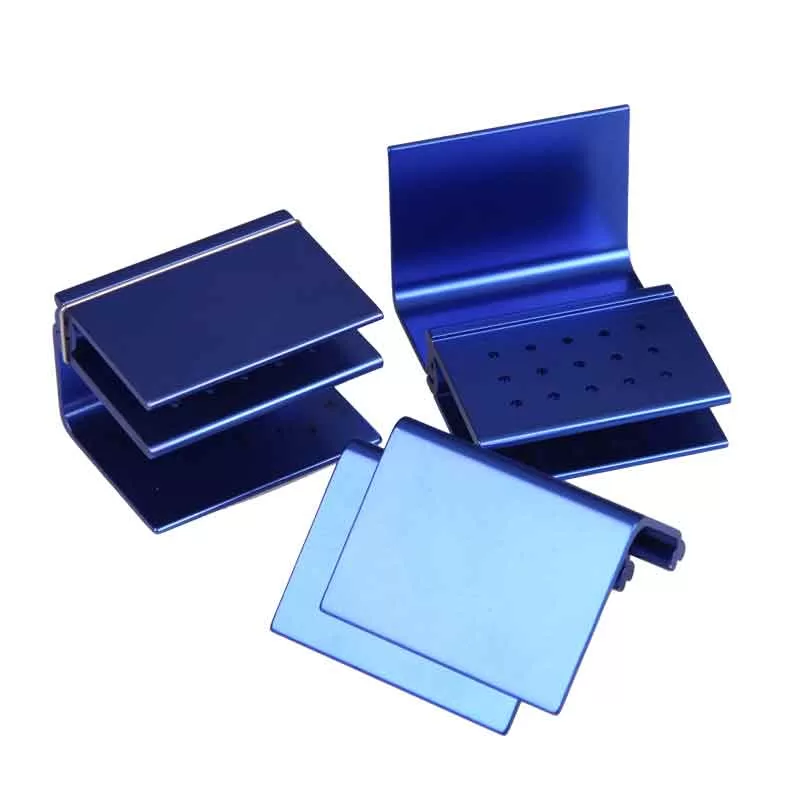

- MRI and X-Ray components

- Monitoring equipment components

- Tables and panels

- Physiotherapy apparatuses

- Electronic equipment components

- Prostheses

- Medical delivery systems

- Fluid management systems

- Biotechnology components

- Respiratory devices

- Handheld devices

- Diagnosis equipment

- Ultrasonic equipment

- Care equipment

- Medical carts

Medical device Manufacturing Capabilities

Rapid CNC machining

Rapid 3D printing

Rapid tooling

Rapid sheet metal prototyping

Medical device FAQs

Yes, GreatLight Rapid Prototyping is an ISO9001-2015 certified manufacturer. We manufacture parts to a high standard, no matter the project or the customer.

For certain manufacturing processes like injection molding, we can provide a T1 sample for your parts, then further samples if required.

We can fulfill orders quickly, but lead times depend on a few factors, such as the manufacturing process, order quantity, and part complexity. CNC machined parts can take as little as five days, 3D printed parts can take as little as three days, while moldings made via rapid tooling can take as little as 5–7 days.