introduce

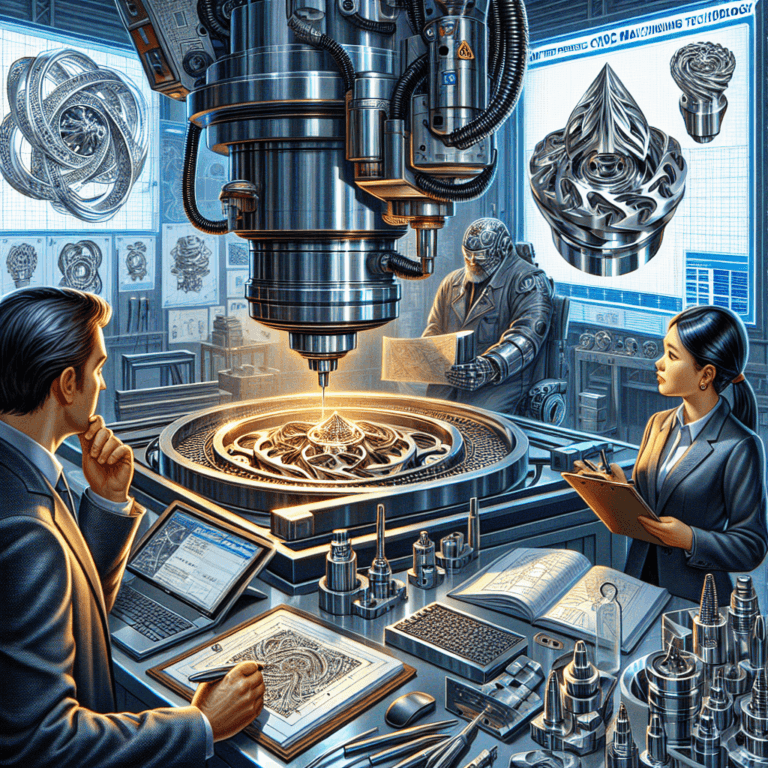

In the ever-evolving world of manufacturing, high-precision CNC (computer numerical control) machining has become a game-changer. The technology bridges the gap between automation and precision craftsmanship, allowing manufacturers to produce intricately designed parts with unparalleled precision. High-precision CNC machining technology has become an essential technology in industries ranging from aerospace and automotive to medical device manufacturing. In this article, we’ll delve into the fundamentals of CNC machining, explore advanced technologies, and discuss the future of high-precision machining.

Learn about CNC machining

What is CNC machining?

CNC machining is the process of manufacturing parts and components using computer-controlled machines. The technology can automate traditional machining processes such as milling, turning and drilling. By feeding computer programs into CNC machines, operators can produce parts with high repeatability and minimal human intervention.

How CNC machine tools work

CNC machine tools control the movement of cutting tools and workpieces through a series of commands. These commands are generated from CAD (computer-aided design) files and then converted into G-code – a programming language that CNC machines understand. The precision of these machines is largely due to their ability to perform complex calculations and movements with extremely high precision.

Key components of CNC machining

1. Computers and Software

The core of CNC machining is the computer system running the software responsible for generating machining instructions. Common software includes CAD for designing parts and CAM (computer-aided manufacturing) for creating G-code that tells the CNC machine what to do.

2. Types of CNC machine tools

There are many types of CNC machine tools, each suitable for specific machining tasks:

- CNC milling machine: Mainly used for cutting, drilling and forming materials.

- CNC lathe: Ideal for turning operations where the material is rotating relative to a fixed cutting tool.

- CNC milling machine: Suitable for wood and softer materials, often used in signage and cabinetry.

- CNC plasma cutting machine: For cutting thick materials and metals using a plasma torch.

- CNC laser cutting machine: Uses a focused laser beam to provide precise cutting capabilities.

3. Cutting tools

High-precision CNC machining uses a variety of cutting tools designed for specific materials and applications. Tool selection affects surface finish, machining accuracy and production speed.

The Importance of CNC Machining Precision

Tolerance levels and their impact on quality

In the world of CNC machining, tolerance refers to the acceptable limit of physical dimensional variation. Precision machining aims to produce parts that meet specified tolerances, which is critical for applications that require tight fit and interoperability. High-precision tolerances can significantly improve the overall functionality and longevity of components.

Surface finish and its significance

The surface finish of a machined part affects not only its aesthetics but also its performance. The smooth surface finish reduces friction and wear, making components more efficient, especially under high loads. Advanced CNC machining technology can achieve various levels of surface finish according to specific requirements.

CNC machining advanced technology

1. 5-axis machining

5-axis machining is a major advancement in CNC technology, allowing simultaneous movement along five different axes. This feature enables the production of complex geometries and reduces the need for multiple setups, greatly increasing efficiency and accuracy.

Advantages of 5-axis CNC machining

- Increase flexibility: Complex shapes can be machined in one setup.

- Improve accuracy: Reduce alignment errors and improve part quality.

- time efficiency: Reduce production time by minimizing manual operations.

2. Multi-task CNC machine tools

Multi-task CNC machines combine multiple machining processes into one, combining milling, turning, drilling and sometimes even additive manufacturing capabilities. This versatility reduces production time and increases overall efficiency.

3. Adaptive processing

Adaptive machining involves using real-time data to dynamically adjust machining parameters. By integrating sensors and feedback loops, CNC machine tools can adapt to changes in material properties or tool wear, ultimately optimizing performance and accuracy.

4. Automation and robotics in CNC machining

Integrating automation and robotics into CNC machining provides significant advantages in speed, accuracy and operational efficiency. Automated systems can quickly reposition components, load materials and perform machining tasks, transforming traditional workflows.

5. Use of artificial intelligence and machine learning

The latest trends in CNC machining incorporate artificial intelligence and machine learning algorithms to enhance operational capabilities. By analyzing historical data, these systems can predict tool wear, optimize cutting parameters, and even anticipate maintenance needs to ensure machines are running at peak efficiency.

The role of materials in high-precision CNC machining

1. Selection of materials

In high-precision CNC machining, material selection is crucial. Commonly used materials include:

- Metal: Aluminum, steel, titanium and various alloys.

- plastic: PVC, polycarbonate and nylon.

- composite materials: Carbon fiber and fiberglass materials.

Material properties determine the best machining strategies, tool selection and finishing techniques.

2. Material properties that affect accuracy

Certain material properties can affect the accuracy of CNC machining, including:

- hardness: Affects tool selection and processing speed.

- tensile strength: Affects the forces experienced during machining, affecting tool wear and finishing quality.

- thermal conductivity: Affects heat generation during machining, causing warping and affecting tolerances.

Best practices for achieving high precision in CNC machining

1. Regular maintenance of CNC machine tools

Ensuring that your CNC machine tools are in top condition is crucial to maintaining accuracy. Regular maintenance should include:

- calibration: Routine inspections and adjustments to ensure accurate machine operation.

- clean: Keeps machine free of debris and contaminants.

2. Tool selection and replacement

Choosing the right cutting tool for the material being processed is crucial. High-quality cutting tools should be inspected regularly and replaced as needed to maintain the integrity of the machining process.

3. Optimization of cutting parameters

Fine-tuning cutting parameters such as speed, feed rate and depth of cut can optimize the machining process and reduce material waste, thereby increasing overall accuracy and productivity.

4. Implement quality control measures

Employing strict quality control processes, such as dimensional inspections and surface finish inspections, can detect problems early and ensure that machined parts meet accuracy requirements.

The future of CNC machining

technological innovation

As technology advances, the following innovations may appear in the future of CNC machining:

- Internet of Things (IoT): Enhance machine connectivity to enable real-time monitoring and predictive maintenance.

- virtual and augmented reality: Provides an immersive training environment and facilitates real-time operational adjustments.

Environmental protection practices

Sustainability is becoming increasingly important in manufacturing. Future CNC machining practices may involve the use of environmentally friendly materials, waste reduction technologies and energy-efficient machines.

in conclusion

High-precision CNC machining technology is revolutionizing the manufacturing landscape and driving improvements in productivity, quality and efficiency. By leveraging state-of-the-art technology and strictly adhering to best practices, companies can master high-precision machining techniques to ensure robust production and market competitiveness. Looking to the future, the continued integration of innovative technologies will further redefine CNC machining and set new benchmarks for accuracy and performance.

FAQ section

1. What is the difference between CNC processing and traditional processing?

CNC machining utilizes computer-controlled processes to increase precision and efficiency, while traditional machining relies on manual processes that are more prone to human error.

2. What types of materials can be processed with CNC technology?

CNC machining can handle a variety of materials, including metals (such as aluminum and titanium), plastics (such as PVC and nylon), and composites (such as carbon fiber).

3. What is the role of G code in CNC machining?

G-code is a programming language used in CNC machining that instructs the machine how to move, what tools to use, and cutting parameters.

4. How to improve the accuracy of CNC machining technology?

Improving accuracy involves regular machine maintenance, selecting the right cutting tools, optimizing cutting parameters and implementing strict quality control measures.

5. What are the common industries that use CNC machining technology?

Industries that frequently use CNC machining include aerospace, automotive, medical device, electronics, and consumer product manufacturing.

6. How to improve accuracy in five-axis machining?

Compared to traditional 3-axis machining, 5-axis machining allows complex geometries to be created in a single setup, minimizing alignment errors and improving part accuracy.

7. What maintenance measures are recommended for CNC machine tools?

Regular maintenance practices should include machine calibration, routine inspections, tool replacement and debris removal to ensure optimal performance and accuracy.

This comprehensive guide is designed to provide in-depth knowledge about high-precision CNC machining technology while maintaining a keyword density of approximately 1-2%. By understanding these principles and practices, industries can achieve excellence in quality and efficiency, ensuring their competitive advantage in the marketplace.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.