Mechanical properties of materials refer to the different physical properties and deformation behaviors of materials under the action of external forces. These properties are important indicators for evaluating the suitability of materials under different application conditions. Here are some key mechanical properties and their interpretation:

Ten mechanical properties

01Intensity

tensile strength

Definition: Maximum stress a material can withstand before breaking during a tensile test.

Importance: A measure of the bearing capacity of a material under tensile loads, often used in the design and analysis of structural members.

Yield strength

Definition: Stress value when the material begins to undergo significant plastic deformation.

Importance: One of the key parameters that determines the maximum load a material can support without permanent deformation.

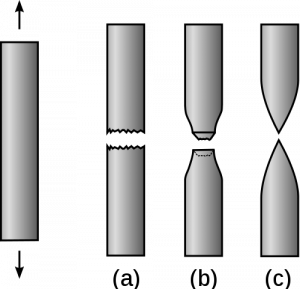

Compressive strength

Definition: The maximum stress that a material can withstand under compressive loading until failure occurs.

Importance: Used to evaluate the performance of materials under pressure, such as columns, bases and other structures.

Shear resistance

Definition: The maximum stress at which a material fails under shear loading.

Importance: Used to analyze the bearing capacity of connectors, bolts, etc. under a shear force.

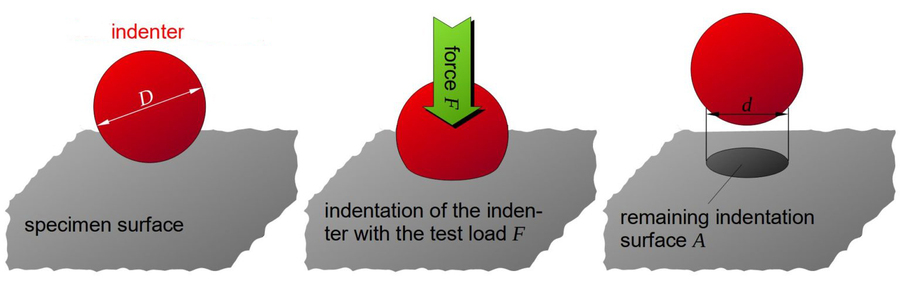

02 hardness

Definition: The ability of a material surface to resist being dented or scratched by hard objects.

Importance: Hardness is related to wear resistance and scratch resistance and is an important indicator for evaluating the wear resistance of materials.

Test method

Brinell Hardness (HB): Use a carbide ball to press the surface of the material and measure the diameter of the indentation to determine the hardness.

Rockwell Hardness (HR): Hardness is determined by driving a conical or spherical indenter into the surface of the material and measuring the depth of intrusion.

Vickers Hardness (HV): Use a quadrangular diamond pyramid to press the surface of the material and measure the diagonal length of the indentation to determine the hardness.

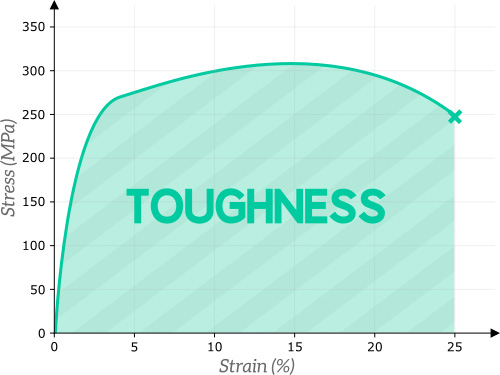

03Resistance

Definition: The ability of a material to absorb energy and deform plastically without breaking, generally measured by impact testing.

Why it matters: High toughness materials are able to resist failure under impact loads and are suitable for manufacturing components subjected to high dynamic loads.

Shock resistance

Definition: The energy absorbed by a material subjected to impact loading, generally measured by the Charpy or Izod impact test.

Application: Evaluate material performance in low temperature or high impact environments.

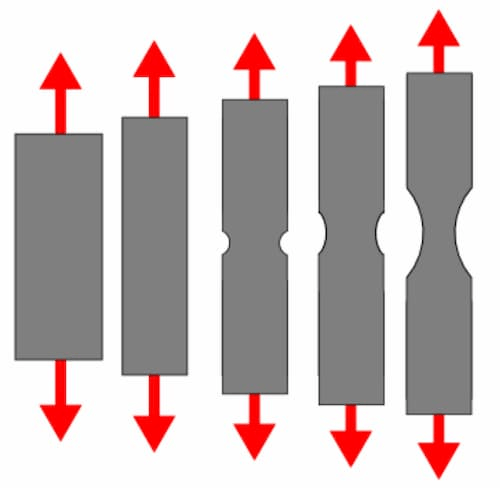

04ductility

Definition: Ability of a material to deform plastically under stress without breaking, generally expressed by an elongation and reduction in surface area.

Why it matters: Ductile materials can stretch, compress, or bend during processing without cracking, making them suitable for making parts with complex shapes.

Elongation

Definition: degree of deformation of a material before failure during a tensile test, as a percentage of its original length.

Application: Used to evaluate the plastic deformation capacity of materials.

Shrinkage of the area

Definition: Reduction in cross-sectional area as a percentage of the original area after the material fails in a tensile test.

Application: Evaluate the ductility of materials in conjunction with elongation.

05 fragility

Definition: Property of a material to fracture without significant plastic deformation when subjected to stress.

Why it matters: Brittle materials often break suddenly without significant deformation. Very brittle materials should be avoided in designs, particularly under dynamic loading or impact conditions.

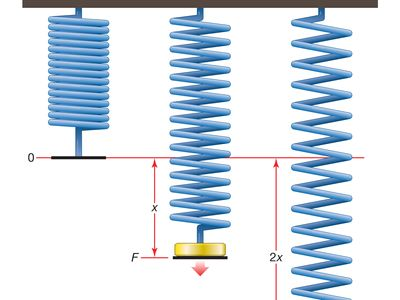

06 Flexibility

Definition: Ability of a material to deform under the action of external forces and to return to its initial shape once the external forces are removed.

Why it matters: The modulus of elasticity (Young’s modulus) is a measure of a material’s ability to resist elastic deformation and is often used in the design of elastic elements such as springs.

elastic modulus

Definition: The proportional relationship between stress and strain, indicating the stiffness of the material.

Application: Used to calculate the deformation of materials in the elastic range and evaluate the stiffness and elastic recovery capabilities of materials.

07Fatigue resistance

Definition: The ability of a material to withstand millions of repeated loads without breaking under cyclic stress.

Importance: Fatigue resistance is related to the lifespan of materials and is an important indicator for evaluating the long-term performance of materials under dynamic loads or in vibration environments.

application

Suitable for dynamic components: Components subject to cyclical loading, such as shafts, springs and gears, require materials with high fatigue resistance to extend their service life.

08 Creep

Definition: Slow plastic deformation of materials over time under the action of high temperature or constant stress.

Importance: Creep is one of the leading causes of material failure in high temperature environments and is particularly critical in high temperature equipment such as turbine blades and boiler pipes.

Creep resistance

Definition: Ability of a material to withstand long-term loads at a certain temperature without creep failure.

Application: Used to evaluate the long-term performance of equipment materials at high temperatures.

09Breaking strength

Definition: Capacity of a material to resist crack propagation, maximum stress intensity factor that the material can withstand in the presence of existing cracks.

Importance: Used to evaluate the material’s ability to resist failure in the event of cracks or defects, particularly important in parts with high reliability requirements.

10 Anti-fatigue performances

Definition: The ability of a material to resist fatigue damage and fracture under cyclical stress conditions of repeated loading and unloading.

Importance: For components subject to cyclic loads, such as flywheels, shafts, springs, etc., fatigue resistance is crucial and determines their service life.

The mechanical properties of materials are important indicators for measuring the performance of materials under various loading conditions. These properties directly affect the application range, service life and safety of the materials. In engineering design, understanding and rational selection of mechanical properties of materials can ensure that product reliability, durability and performance meet design requirements.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.