existBefore the advent of 3D printing, industrial designers sculpted foam, machined wood and molded clay, slow and labor-intensive processes. SOThe industry quickly accepted3D printing.

Here we talk to leading industrial designers about how they use3D printing, the printers they rely on, and their tips for getting the most out of your printer purchase.

3D printers: industry tools

Inventindia designers inspect 3D printed parts (Source: Inventindia)

Designers say that while not all industrial design firms have yet3D printers, but the popularity of this technology is growing rapidly because it is cheaper and more accessible than ever.

“Over my career, I have seen 3D printers go from being a novelty, to an expensive tool, to an essential part of design services,” said Nathan Pollock, founder of Katapult Design in Byron Bay, Australia. “Greater reliability, better user experience and better quality all have a significant impact on acceptance. »

Some printer manufacturers offer professional users easier-to-program machines, a wider range of materials, and an integrated ecosystem of software, materials, and training. These advances, combined with falling prices, are attracting more and more committed professionals.

“Currently, 3D printing has become an industrial tool in product design,” said David Block, principal of Studio Redeye in Brooklyn, New York. “If you don’t have a 3D printer and you’re developing products, you’re behind,” echoed Jonathan Thai, co-founder and partner at HatchDuo in San Francisco.

Benefits of 3D printing technology

1. Accelerate your product design

Tone Product Design’s hanging storage pot for Joseph Joseph was first prototyped using 3D printing to verify functionality (Source: Joseph Joseph)

Among the advantages of the technology, designers say:3D printing is essential to speed up the entire creative process.

“The biggest advantage is mainly speed,“We can quickly get concept-level evaluations and adjust or refine our ideas immediately,” Pollock said. “

Pollock said Katapult Design is currently developing closures for baby wipe containers and being able to quickly 3D print and test variations of the design will be very helpful in providing customers with a quick and cost-effective solution.

In addition to the initial proof of concept,3D printers can also deliver functional mechanical parts and complex, multi-component prototypes. In fact, designers say they are able to get closer to the look, feel, and functionality of the final product through 3D printing rather than any other type of in-house prototyping method.

“We print everything from quick block models to test the shape and proportions of a design, to high-fidelity functional prototypes that allow us to refine details or mechanisms,” explains Oscar Daws, director of the product design at Tone in London. “3D printing allows us to quickly iterate on complex shapes and precise details, meaning we don’t have to compromise on prototyping in order to physically test it.”

ForFor the new Joseph Joseph Hanging Storage Jar (pictured above) designed by Tone, the design team used 3D printing from the start to experiment with several options for product proportions. “Once the initial design concept is developed, we use high-resolution SLA printing to refine technical details and test CAD data before manufacturing,” he said.

2、Use printed prototypes to show, not tell

of various materials3D printed prototype (Source: Yoram Reshef Photography Studio)

“In-house 3D printing allows us to show customers physical representations of their future products as well as the design engineering work we have done to date,” said Lucas Lappe, partner at Doris Dev in New York. . “3D printers allow us to stay ahead of the competition, and without a 3D printed prototype, customers are often unaware that their product is in development.”

One of the largest industrial design companies in IndiaSanandan “Sandy” Sudhir, CEO of Inventindia Innovations, also relies on his 3D printers. “With nearly 40 projects underway at any given time, 3D printing is essential to all of our projects,” he said. “We use 3D printed parts early in the design process to produce rapid proof-of-concept models, and we use more refined parts in later stages to assemble first-level functional prototypes. »

Inventindia has used a range of 3D printers for many years and currently runs a range of large format filament and resin printers from Mingda. “3D printing technology has come a long way in the last 20 years,” Sudhir said. “Older technologies such as FDM, SLA and SLS have become so popular and cost-effective that you can buy an FDM 3D printer for as little as $300. On the other hand, the more advanced technologies of HP and Objet allow the use of multiple materials and objects. colors are seamlessly integrated into a single piece, which is more expensive but provides greater flexibility in exploring and creating appearance mockup possibilities.

It can be said that all kinds of3D printing technology is suitable for industrial design, including even metal 3D printing.To save money, you can go directly to Mohou.com.3D printing.

3、Outsourcing industrial design models

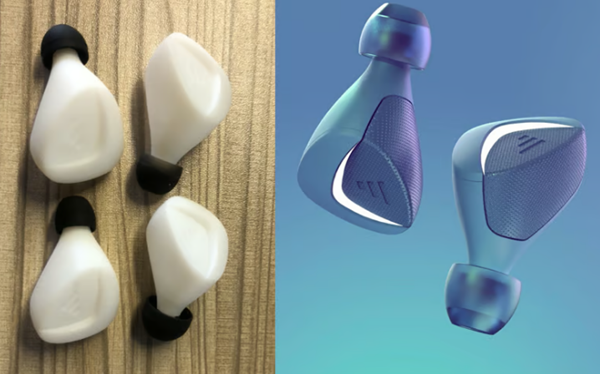

Fantany Unbound headphones, 3D printed prototype and final product (Source: HatchDuo)

Industrial design firms do not need to have their own3D printers can benefit from this technology. There is a boom in global 3D printing services, including Jawstec and Sculpteo, as well as 3D printing service comparison platforms such as Craftcloud.

Together, these services allow designers to order parts in a variety of materials, from rubberized plastic to polished steel, and in sizes up to more than a square meter.

In the short term, ordering parts from a professional service is cheaper than purchasing your own printer, and may even be faster than printing in-house. In addition to offering in-house maintenance technology that most design firms can’t afford, many printing services offer consulting to ensure your prints turn out exactly as expected.

However, in the long term,“Printing in-house should save you money on printing costs and really save you on shipping costs and delivery times on all those parts,” said Ian Peterman, CEO of Peterman Design in Los Angeles.

becauseDesigners still turn to service providers for the complexity of 3D printing, but today many professionals say it’s no longer a big deal.

“Every engineer in the company is trained to manage 3D printers,” Lappe said. “This makes the process accessible to anyone designing and using 3D printed prototypes.”

4、3D Printer Buying Tips

(source:Ultimaker)

Miscellaneous3D printing technologies and printer brands have different advantages and disadvantages in terms of available materials, quality of final printed parts, ease of use, printing speed and cost. To the uninitiated, this can seem like a confusing maze of terms and characteristics.

“Think carefully about what you use it for, because it will have a significant impact on the technology you choose,” Dawes said. “For industrial designers, I recommend starting with a high-quality FDM printer, which will allow you to complete most jobs quickly and inexpensively.”

FDM (fused deposition modeling), or machines that print using spools of plastic filament, can cost anywhere from a few hundred dollars to a few thousand dollars. Material options range from soft plastics to extra-strong plastics, with recyclable and sustainable options also available.

“We prefer to use a regular FDM printer for early proof-of-concept models so we can make quick and dirty prints and test our ideas,” says Sudhir.

FDM is the most common type of 3D printer and the easiest to learn and maintain.

“Buy something that everyone on the team can use,” Rapp said. “It’s simple and doesn’t require a dedicated technician. This makes the printer accessible to more people and integrates it into everyone’s workflow.”

Another type of printer popular with industrial designers is the resin printer, also known as stereolithography orALS. These printers use a vat of liquid resin and generally print with finer details and smoother surfaces than FDM.

“SLA printers are ideal for working with transparent materials to understand issues related to assembly and surface preparation as well as mechanical interference on internal parts,” Sudhir said. “But in general, SLA parts are fragile and therefore not suitable for simulating the precise material properties of plastic parts.”

Although mostSLA materials or resins are fragile, but some are flexible and elastic, and manufacturers are rapidly expanding their product lines to meet the growing demand for texture, color and strength.

5、3D printing service provider

Of course, not every company or engineer can have one.For 3D printers, considering the cost issue, you can seek cooperation with 3D printing service providers. Mohou.com is an excellent 3D printing service platform in China. It can print more than 50 types of 3D printing materials in multiple 3D printing processes. instant quotes, transparency and fairness. All inquiries are welcome.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.