Unlocking Secrets: A Practical Guide to Calculating Hours of CNC Processing Costs

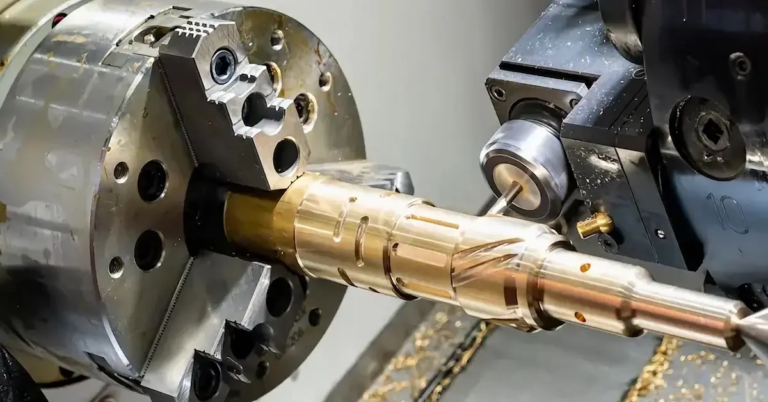

Navigating the world of CNC machining often boils down to one key issue: "how much does it cost?" Need specific project details while getting the final offer how Calculating hourly CNC processing costs allows you to make informed decisions, accurately evaluate quotes, and optimize your design for cost-effectiveness. At Greatlight, as an expert in advanced five-axis CNC machining, we believe transparency is key. This guide reveals the factors behind hourly rates and how to use this knowledge.

Why it is important to understand the cost per hour (exceeding the price)

Just knowing an hourly rate (e.g. $75-$150/hr) is not the whole situation. Understanding this speed thing will help you:

- Evaluate quotes fairly: Distinguish between real value and potentially exaggerated estimates.

- Optimized Design and Design (DFM): Determine the function of disproportionately increasing processing time and cost.

- Accurate budget: Forecasts for more reliable expenditures for prototypes or production operations.

- Establish a supplier trust: Working with stores (such as Greatlight!), its pricing structure is logical and transparent.

Anatomy of the cost of hourly CNC processing

The hourly rate is never arbitrary. This is a calculated synthetic material designed to cover all the expenses inherent in running high-precision manufacturing operations while ensuring sustainability and quality. This is a crash:

-

Machine cost: core investment

- depreciation: CNC machines, especially complex five-axis centers, represent significant capital investments ($100,000 to $1 million or more). It is essential to spread this cost to their operating lives. This is usually the largest single factor.

- Maintenance and repair: Regular lubrication, calibration, calibration inspection, replacement parts and accidental repairs make the machine run reliably and accurately. Ignoring maintenance can lead to expensive downtime and quality issues.

- Tools and fixes (machine specific): We later introduce the initial investment in dedicated fixtures and dedicated tool holders of the machine platform when tool wear is applied, which helps with the basic overhead.

- Setting and calibration time: Loading the program, setting the time it takes to install the tools and fixtures, and ensuring everything is aligned and calibrated perfectly forward Any chip is cut. In production operation, this fixed time is amortized.

-

Labor Cost: Human Expertise Factor

- Operator: A skilled mechanic sets up the work, monitors the machining process, performs manual operations/process inspections, and unloads parts. Five-axis machining expertise commands higher salaries.

- Programmer (CAM): Converting complex 3D models into valid, error-free machine paths (G codes) requires specialized software knowledge and complex machining process understanding. Five-axis programming is more complex and time-consuming than three-axis.

- Engineers and technicians: Handle engineers optimize feed/speed, troubleshoot issues, manage workflows, and ensure quality standards. Maintenance technicians keep complex equipment running.

- Supervision and management: Supervise to ensure smooth operation, schedule and meet deadlines.

-

Tool Cost: Cutting-edge

- Tool consumption: The cutting tool (end mill, drill, insert) wears and eventually breaks. The cost of replacing these tools is the direct operating expenses. Aggressive processing speed/feed (essential in many materials) or hard materials can significantly increase wear and tool consumption.

- Tool inventory investment: Maintaining a diverse range of different materials and operations, a ready-to-use tool library requires significant investment.

- Tool Management: Costs related to tool sharpening/renovation, storage, presettings and traceability.

-

Elevated Cost: Keep Lighting

- facility: Rent/mortgage, property tax, insurance, utilities (high power draws for machines and HVAC).

- administrative: Sales, quotes, purchases, accounting, human resources, IT infrastructure.

- Software License: Critical CAM, CAD, ERP/MRP systems, machine monitoring platforms (annual or subscription fees may be considerable).

- Quality Control Infrastructure: CMM, optical scanner, micron, surface tester, vision system – its purchase, calibration and maintenance.

- Profit: Sustainability and Growth

- A reasonable profit margin is essential for any business to invest in new technologies, continuous improvement, employee training, a downturn in the weather and a long-term partner that remains a reliable one.

Five-axis advantages and cost nuances

While five-axis machining involves a large amount of upfront technology investment and a highly professional workforce (resulting in higher base hourly rates), it usually provides Total cost savings For complex components:

- Reduced settings: Complex geometry that requires multiple settings on a three-axis machine can often be done in a single setup, greatly reducing setup time and cumulative errors.

- Faster material removal: Optimized tool orientation can be more aggressive cutting parameters and longer tool life in certain situations.

- Improve accuracy: Less processing can reduce potential errors between settings.

- Complexity processing: Create features on a 3-axis machine that combines parts and eliminates secondary operations (such as custom fixtures for precise angles).

How Greatlight Optimizes Your CNC Processing Cost

Understanding cost drivers is not only theoretical for us; this is how we provide extraordinary value:

- Advanced Technology: Our high-efficiency five-axis minimizes cycle time through speed, accuracy and reduced settings.

- DFM in-depth expertise: Our engineers proactively analyze your design to come up with subtle modifications that greatly reduce machining time (e.g., adjusting internal radius, taper ratio) without sacrificing functionality – We take the initiative to find ways to save money.

- Optimized tool strategies: Maximize material removal with cutting-edge tool paths (HSM/HSC, Trochoidal milling) while minimizing tool wear and extending life.

- Simplify operations: Effective workflow management and verification processes minimize non-cutting time.

- Integration post-processing: As a one-stop solution for providing finishing (anodization, plating, painting, heat treatment), we eliminate the markings from multiple suppliers and effectively manage the entire process.

Conclusion: Accurate partners, profit from expertise

Understand the components of an hour’s CNC machining cost to transform dynamics from opaque pricing to informed collaboration. It emphasizes that the lowest rate is not always the best value – such as machine capabilities (especially advanced five-axis efficiency), deep DFM knowledge to reduce machining time, consistent quality and reliability are crucial.

At Greatlight, we leverage state-of-the-art five-axis technology and extensive manufacturing expertise to deliver precisely designed solutions and Cost-effective. We not only offer rates; we offer partnerships that focus on optimizing the success of your project. When complexity, speed and accuracy are important, believe Greatmight is your preferred CNC machining service and excellent value. Quote your custom exact parts now and experience the Greatlime difference!

FAQ: Hourly CNC processing costs

-

Q: What factors cause the hourly CNC machining rate to vary between stores?

- one: Key factors include machine type/age/reputation (3-axis vs. 5-axis brand new vs. old), store location and overhead (labor price, facility cost), material expertise, level of automation, level of quality certification, level of quality certification (ISO), store focus (work store vs. high quantifiable production), and store specific cost structure and margin requirements.

-

Q: Is it possible to use a five-axis machine? always The cost per hour is higher than 3 axes?

- one: Often, yes, due to the higher cost of machine capital, specialized programming and operator expertise. However, For parts with complex geometric parts, it usually results Lower total project cost By greatly reducing the setup and total machining time, secondary operations may be eliminated. For simple parts, 3-axis is often more cost-effective.

-

Q: Can I reduce the cost of the hour by providing my own materials?

- one: While possible, stores like Greatlime often get materials at higher prices through bulk supplier relationships. Providing your own material saves your material marking, but Hourly rate The fees charged by the store are still the same to cover their production overhead and expertise. Make sure that the materials you provide meet specifications and certifications.

-

Q: How important is the cost of cutting tools? Who pays for tools is broken?

- one: The tool cost is significant and is directly part of the hourly rate calculation. Wear continues to occur. The risk that is often considered to be covered by the store’s hourly rate or incorporated into its operating costs. Extremely rupture due to unforeseen issues (such as inclusions in materials) usually handled or agreed upon in the terms of the store, without charging each failure alone.

-

Q: How does the quantity of parts affect effective hourly costs?

- one: The machine setup and programming costs are relatively fixed. For larger batches, this fixed cost is distributed on more parts, greatly reducing costs Each unit. cost Each section (which includes machine time and labor) also often reduces the peak of operational efficiency and tool routing optimization with the first few pieces.

-

Q: In addition to the hourly rate, what other fees are included in the final CNC processing quote?

- one: A comprehensive offer will include:

- Material Cost: Original stock.

- Setup cost: Amortize the initial computer/operator time setting cost during operation.

- Programming time cost: Used to generate machine code (more important for complex or 5-axis work).

- Machine runtime cost: According to the hour rate per part/run and the estimated machining time.

- Completion fee: Post-treatment services such as burrs, polishing, anodizing, plating, painting.

- Quality control and inspection: The cost of measuring and ensuring that parts meet specifications.

- Packaging and shipping.

- one: A comprehensive offer will include:

- Q: How to get the most accurate cost estimate from Greatlight?

- one: Provide us with detailed, manufacturable CAD files (higher steps or IGES), specifying your exact materials, the required quantity, the required tolerances, surface finish, and any necessary post-treatment. The more precise the requirements, the more accurate our DFM reviews and quotes will be. Contact us today for a quick expert quote!