1 Preface

The combustion chamber shell of a certain type of engine is made of a front connection part, a thin-walled rotating cylinder, a rear connection part and a support through a combination argon arc welding, heat treatment and sandblasting. The outer surface of the thin-walled combustion chamber shell is welded with 2 rows of axial supports, a total of 20 supports. The design drawing of the brackets requires the thread precision to be M4-6H. The bracket thread is used to install the missile cable cover, and the quality and reliability of the threaded connection must be high. Due to the limitations of the supporting structure, materials and spatial structure of the welding point with the combustion chamber shell, the traditional process is used to process the threads, and the product qualification rate is low. This paper carries out process analysis and research on all aspects of product processing, and obtains a reasonable and effective thread accuracy control method through experimental verification, comparison and analysis.

2 Product structure characteristics and processing difficulties

2.1 Structural characteristics

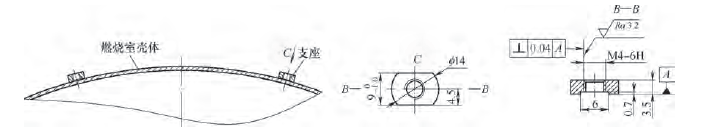

The external dimensions of the combustion chamber shell are relatively large, with an outer diameter of 500 mm and a length of 4,500 mm. The bracket is manually welded to the outer surface of the combustion chamber shell and its radial span is (114 ± 0.2) mm. The combustion chamber shell and supporting materials are made of D406A ultra-high strength steel. The support structure of the combustion chamber housing is shown in Figure 1. The shape of the support is an oblong structure, with an outer diameter of 14mm and a width of mm. There is an internal M4-6H thread in the center with a pitch of 0.7mm. There is only a 0.7mm gap between the threaded bottom groove and the thin-walled housing.

Figure 1 Combustion chamber housing support structure

2.2 Processing difficulties

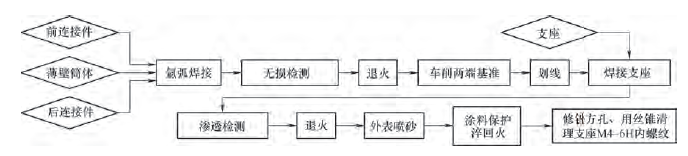

The process of processing the bracket is shown in Figure 2. If the threaded hole of the bracket is planned to be processed after welding and heat treatment, there are several difficulties:[1]。

1) The gap between the bottom of the threaded hole of the bracket and the housing is only 0.7mm. The surface of the thin-walled casing is easily damaged during machining, causing quality risks.

2) The gap between the groove at the bottom of the threaded hole of the bracket and the shell is small, the tap guide is short during thread processing, and the positioning is unstable. It is difficult to tap the thread and it is easy. to deal with the deviation. The verticality of 0.04mm cannot be guaranteed.

3) The hardness of the material after heat treatment is 48~52HRC. The tap may easily break during thread processing, and the shell may be scrapped due to thread problems, thereby increasing manufacturing costs and quality risks.

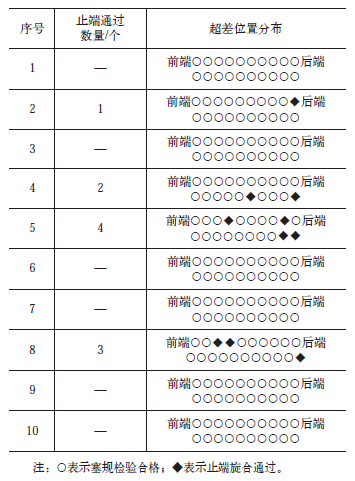

Based on the above analysis, it can be concluded that the bracket thread should be processed before welding, and after welding, it is annealed, sandblasted, quenched and tempered with the combustion chamber shell. After quenching treatment, the bearing thread surface is oxidized, and the excess material is attached to the thread profile surface. If the bracket threads are field processed before welding, after assembly and processing of the combustion chamber shell, use an M4-6H tap to clean off the excess attached to the surface of the bracket thread profile . This will also cause the bracket to thread. oxide layer on the surface of the internal thread profile of the bracket to fall off. When tested with M4-6H thread stop gauge, the success rate is only 67%. Statistics were compiled on the processing of M4-6H internal threads of 17 pieces of combustion chamber housing brackets. The data is shown in Table 1. How to improve the machining accuracy of bearing thread has become an urgent technological problem that needs to be solved during product production and delivery.

Figure 2 Flow of the treatment process

Table 1 Processing statistics of M4-6H internal thread of 17 pieces of combustion chamber housing brackets

3 Technical solutions and process testing

3.1 Technical solutions

After examining, testing, analyzing and troubleshooting each processing process of the combustion chamber shell and bracket, it is believed that the main reason for the excessive dimensional accuracy of the M4-6H internal thread of the bracket is: after the quenching treatment, the thread surface of the bracket is oxidized and the thread has excess material attached to the tooth surface. When cleaning the excess on the thread surface, the oxide layer on the internal thread profile surface of some brackets will fall off, resulting in poor accuracy of the internal threads of the M4-6H bracket.

Based on the process analysis, two process plans were developed.

Option 1: Customize a special hand tap, divided into a first cone and a second cone, and control the average diameter of the first cone. Use a cone to tap the thread as a support part and leave a machining allowance. After heat treatment of the combustion chamber shell, the bracket thread is tapped with a second taper to ensure final thread accuracy.

Option 2: Improve the precision of M4-6H thread by one level in the state of the supporting part and process it according to M4-5H, effectively making up the difference between M4-6H and M4-5H and meeting the requirements of thread accuracy[2]。

3.2 Testing process and results

The first process plan takes place in 3 steps. ① Customize special taps (head cone and double cone), and the margins reserved for the nose cone diameter are 0.30mm, 0.20mm and 0.10mm respectively. ② Use a cone to tap the thread when processing supporting parts. ③After heat treatment, use two cones to tap the wire. Due to the high hardness of the material after heat treatment (48-52HRC) and the larger diameter structure of the combustion chamber shell, it becomes more difficult for the operator to tap the thread, the force is uneven and the cutting force is easy to deflect from the axis. During the test, when the tolerance of the pitch diameter is 0.30mm, the threaded hole cannot be cut when tapping with a two-cone taper; when the pitch diameter tolerance is 0.20mm and 0.10mm, the threaded hole is deviated or the tap is broken. , and product quality Difficult to guarantee[3]。

According to the second process plan, the precision of the bracket thread is improved by one processing level, and the processing state of the M4-6H internal thread of 10 pieces of combustion chamber shell brackets is statistically analyzed. in Table 2. The thread accuracy has been greatly improved, and the product qualification rate has increased from 67% to 95%.

Table 2 Support internal thread processing statistics in Figure 2

3.3 Analysis of test results

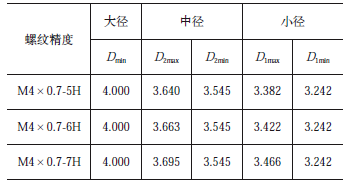

Through summary analysis of the test results of Scheme 1 and Scheme 2, according to the processing method of Scheme 2, the qualification rate of the bearing thread has been significantly improved. Use M4-7H thread gauge to inspect out-of-tolerance threads, and all are qualified. Compare the thread precision dimensions of M4-6H with those of M4-5H and M4-7H. See Table 3 for details.

Table 3 Precision dimensions of M4 × 0.7 mm internal thread (unit: mm)

It can be seen that the size of the pitch diameter of the M4-5H thread ismm, the average diameter size M4-6H is

mm, the average diameter size M4-7H is

mm. The difference in the maximum limit size deviation between 7H and 6H is 0.032 mm, and the difference in the maximum limit size deviation between 6H and 5H is 0.023 mm, that is, the deviation precision of unqualified bearing thread does not exceed 0.032. mm. In order to compensate for the out-of-tolerance, the thread accuracy in actual processing is increased to 5H, and the compensation amount is 0.023mm, which can basically meet the requirements of thread compensation amount. For situations outside the tolerance of individual threading precision, it can be considered that the degree of out of tolerance is very low and that the precision is between 6H and 7H.[4]。

4 Improvement measures and process verification

The processing process is settled and the product qualification rate has been significantly improved, which indicates that the processing method is reasonable and feasible. Through the analysis of out-of-tolerance elements, it is believed that the accuracy of out-of-tolerance threading is caused by detailed factors in the machining process. In order to completely solve the problem of bearing thread accuracy, process improvements are made in the following aspects of the bearing processing process.

1) When tapping a thread on a tapping machine, the spindle will vibrate slightly as the processing depth changes, the cutting time at the mouth of the thread is relatively long, and there will be a slight size difference between the threads. mouthpiece and thread. root. The wire is tapped to the back of the bracket wire to compensate for slight changes in the mouth and root during treatment.[5]。

2) Improve the detection accuracy of thread stop gauge. The bearing threads are always machined to M4-5H precision. When inspecting with a threaded plug gauge, the pass gauge should be screwed in completely, and the number of turns of the stop gauge should not exceed 1 turn.

3) The bracket threads must be protected during the sandblasting process before heat treatment of the combustion chamber shell. Change the previous protection method with M4 screws and redesign the special protection screws with an accuracy of M4-6f, and control it. screwing length of the threads in 1 turn maximum to avoid wear due to multiple turns.

4) Change the cleaning method. After the entire combustion chamber shell is machined, first use compressed air to blow the excess into the threaded hole of the bracket, and then use the M4-6H threaded plug gauge to inspect it . If it can’t pass, first use M4 screws to clean, then use M4-5H tap to clean, and after cleaning, use M4-6H thread plug to check.

After several tests and process verifications, the bearing thread accuracy fully meets the product accuracy requirements, and the product qualification rate has been increased to 100%, completely solving the bearing thread accuracy problem.

5Conclusion

In order to ensure the high reliability of the supporting thread after welding and heat treatment, the following measurements are used to control the precision of the thread.

1) In the part state, the thread accuracy is improved by one level of processing, and the bracket thread accuracy is adjusted from M4-6H to M4-5H.

2) When processing the bracket thread, process it from the welding surface (rear side) and detect it from the front after heat treatment and quenching to compensate for the size difference between the mouth and the root during processing .

3) Special guard screws are designed for the sandblasting process to reduce the extrusion of threaded holes.

By taking various technological measures, the thread processing accuracy is controlled, the reliability of the threaded connection has passed the missile flight test evaluation, and the product quality is stable and reliable.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.