Master the basics: Basic setup practices of HAAS VMC

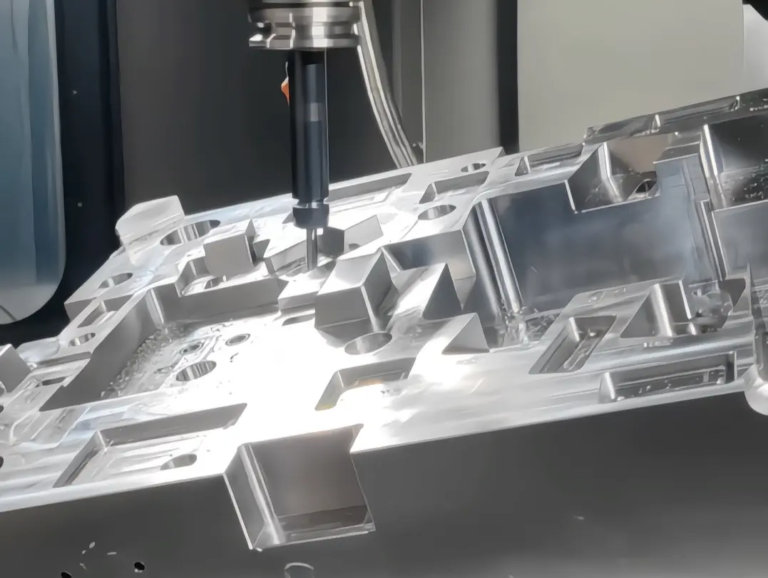

HAAS Vertical Machining Center (VMC) is everywhere. They provide reliable performance, user-friendly control and robust construction that makes it hosted in countless stores. But, like any powerful tool, their effectiveness depends on one basic step: set up. A meticulous order of setup is not only about getting the machine running; it is the cornerstone of achieving consistent, high-precision results, maximizing productivity, minimizing scrap and protecting your valuable investment. This guide explores the core setup essentials that every mechanic and programmer needs to know to maximize the potential of HAAS VMC.

Key pillars for preset preparation

Basic work is crucial before a single tool comes into contact with metal. Ignoring this can cause errors and delays.

-

Thorough cleaning and inspection:

- Inside the machine: Visually check whether the work envelope is from debris, chips or coolant residue from the previous job. Clean the table, spindle nose, tool changer swivel wood bag and lid cover with compressed air and shop rags. Check for coolant leakage.

- Tool bracket and pull stud: Check the holder for damage, thrust (using the test indicator) and cleanliness, especially taper and retaining knob grooves. Make sure to twist the pull stud to the exact HAAS specification (critical for retaining safety tools). Contaminated or damaged taper results in poor spindle contact and thrust, killing accuracy.

- Machine Warm Up: If the machine is idle (especially overnight), perform a HAAS warm-up plan. This allows for even expansion of spindle bearings, ball screws and linear guides under controlled conditions, stabilizing thermal growth and ensuring predictable accuracy in the first section.

-

Tools Strategy and Presets (Offline as King!):

- Optimization Tool List: Analyze the program (G code) to identify the necessary tools. Group operations to minimize tool changes. Consider tool life and spare parts plan.

- Offline presets: For efficiency, this is not negotiable. Set tool length and tool diameter external The machine uses high-quality presets. This eliminates machine downtime caused by manual tool touch, greatly reduces setting time, minimizes spindle collisions during setup, and inputs highly accurate offset data input directly into the control.

- Security Verification: As the tool is loaded into the carousel pocket back Preset, double check that it is the correct pocket number that matches your tool list. Listen to the unique clumsiness of the tool shifter that is correctly involved.

- Worker: Accurate anchor points

- Select the correct fixture: Choose a labor solution (VISE, fixed panels, custom lamps, tombstones) that provides maximum rigidity, tool accessibility, and secure clamping for specific part geometry. Inadequate overhanging and clamping force are the main culprits of tremor and movement.

- Detailed placement and alignment: Please carefully clean the machine tool and fixtures before installation. Avoid chips at all costs! Use an exact alignment tool (indicator mounted on the spindle) to be exactly parallel/perpendicular to the machine axis. Browse here to introduce inherent geometric errors in each section.

- Some locations: The workpiece is securely clamped, checking that the reference data is accessible, and the repeatable location is not blocked yet. Make sure the fixture clears the tool path.

Execute the in-machine setup sequence

Once the preparation is complete, focus shift to configure the machine controls.

-

Establish a working coordinate system (WCS): Find "zero"

- G54-G59 selection: Determine which job offset register will control the job (usually G54).

- Select Detection:

- Edge Finder (Mechanical): Simple, cheap. Touch the sides to manually find the X/Y edge; operator skills and care are required to avoid deflection. Best for lower volume/complexity.

- Detector (Renishaw): The gold standard of speed and accuracy. Easily detect holes, bosses, edges and surfaces. Automatically calculate offsets with incredible accuracy and store them directly. Strict settings are highly recommended.

- Z-axis zero: The most common is on the top of the workpiece or lamp reference. Use the preset tool ("Main Tool" Method), preset height offset, or directly detect surfaces. Consistency of the method is key.

-

Loading and verifying program settings:

- Program transfer: Safely load CNC programs (via USB, network DNC or HAAS memory). Double check filenames correspond to the correct job.

- Dry and simulation: The most overlooked step! Before the attack cycle begins:

- Start the program with the z-axis

Optional StopEnable (M01) and set the positive Z-axis offset (for example,+10.0 mm). - Track the entire tool path visually "Dry running" in reduced feed rate mode. Listen to unexpected sounds. Use the integrated HAAS graphics to simulate potential collisions between inspection tools, holders, fixtures and workpieces. Don’t try to skip this!

- Start the program with the z-axis

- Verification and first-time security:

- Single block start: Use the first few blocks of the program

Single BlockMode andFeed Holdcarefully observe the initial movement. - Verified raw materials: Ensure the original inventory is properly fixed and the correct positioning relative to the WC. Verify that the size exceeds the required part size.

- Prevent tool rupture: Set the first part to conservative speed/feed ($t01 H01 D01 check!). Carefully monitor the first cut.

- Process Check: Before completing the entire cycle, check the critical dimension early in the first part (e.g., being cut in the pocket or boss) to verify the accuracy of the setup. Use portable metering tools such as calipers or instruments.

- Single block start: Use the first few blocks of the program

Conclusion: Accuracy based on perfect preparation

It is not accidental to achieve peak performance and consistent quality from HAAS VMC. This is a direct result of the practice of disciplined system setup. Each step outlined here, from preset critical cleanliness preparation and strategic offline tools to rigorous workforce alignment and a critical safety net for dry runs/simulations, helps minimize errors, reduce unplanned downtime, protect equipment and ultimately increase profitability.

In Greatlight CNC machining, these setup principles are deeply rooted in the daily workflow of our advanced HAAS and five-axis CNC machines. Our mechanics are experts in effectively browsing the nuances of machine settings, ensuring fast turnaround without compromising the accuracy required for complex custom metal parts. We not only use deep process knowledge to operate machines, but also optimize them for every unique project. This mastery, combined with our comprehensive in-house post-processing and finishing capabilities, enables us to provide a truly one-stop solution for precision parts and process most materials to meet your most demanding specifications. Experience the difference in meticulous setup – Get a custom CNC machining quote now and see why Greatlight is the benchmark for quality and reliability.

FAQ: HAAS VMC setup essentials

Q1: How important is it in the key to cleaning the spindle taper before inserting the tool holder?

one: Absolutely critical. Even microscope dirt or oil film can cause improper seating of the holder, resulting in excessive jumping, poor tool life, vibration (chat), and potentially catastrophic spindle damage over time. Blow out the spindle and bracket taper with clean dry air.

Question 2: I don’t have offline tool presets. What is the best choice for setting tool offsets on HAAS?

one: While offline presets are ideal, you can use the machine itself:

- use "Tool Setter" (Electronic touch probe for tool) mounted on the table. Suggested method (if any).

- Carefully use precision reference blocks (known heights) on clean machine surfaces. Touch each tool to the block and adjust the length offset. This adds a lot of machine downtime, but is common in stores without presets. Accurately record height.

Q3: How often should I re-install the fixture?

one: It depends to a lot on the use, fixture design and required accuracy. For production environments where most fixtures are still installed:

- Check after initial installation, tighten the clamp or any significant impact.

- If micron-scale accuracy is essential, periodic checks are performed weekly or after running a large number of batches. If you remove and reinstall the fixture, be sure to resurge.

Question 4: What are the biggest risks of skipping dry running and graphic simulation?

Answer: The machine crashes. This is the most expensive consequence. Undetected errors, work offsets, tool offsets or position of fixtures in the program may cause the tool to move at high speed to slam the workpiece, vis, fixtures, and even the table/spindle itself. This can damage parts, damage tools and holders, and can cause a lot of expensive repairs to the machine structure or spindle.

Q5: My first part appears slightly in one dimension. Where should I start troubleshooting?

one: Methodically verify each setpoint:

- Work offset (G54, etc.): Redetect/touch the relevant reference for the offset axis (X, Y, or Z).

- Tool Offset: Verify that the correct H and D offset numbers are active (

$CURNT TOOLScreen). Check the actual tool length/diameter measurements. Check the tool for wear/debris. - Fixing device: Check for movement or looseness. Recheck.

- Materials Maintenance: Make sure that the parts do not move during machining.

- Program (if offset check pass): View specific problematic blocks of code in the program with any coordinate errors.

- Machine Accuracy (small dimension): Check whether the machine rebound compensation parameters are always bidirectional.

Question 6: How does Greatlight ensure a quick quote with HAAS VMC?

one: Our expertise goes beyond operations until in-depth process planning and DFM evaluation. By gaining an intimate understanding of HAAS machine capabilities, including setting optimizations such as offline presets, we transform designs efficiently into optimized tool paths and define standardized set sequences for similar parts. Strict setup protocols minimize rework risks, ensuring predictable results and faster project start-up. Our integrated citation software takes advantage of this cost-effective engineering history.