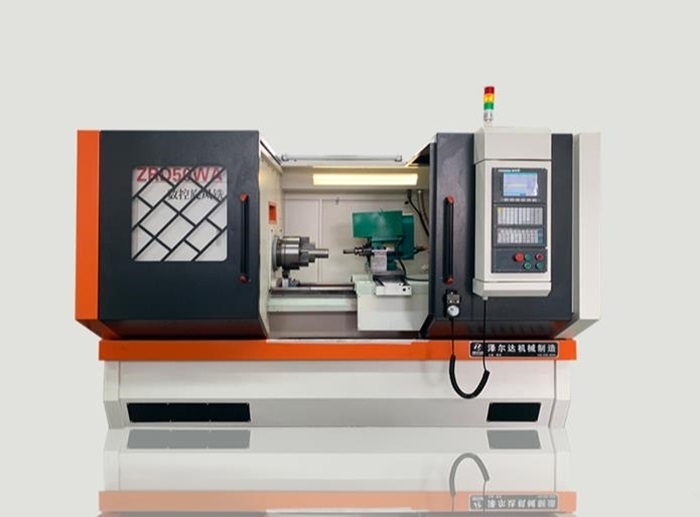

Unlocking the Power of Zelda Cyclone Milling: A Comprehensive Guide to Efficient and Precise Machining

In the realm of modern manufacturing, the pursuit of precision and efficiency is a relentless endeavor. With the constant evolution of technology, innovative machining techniques have emerged to cater to the growing demands of various industries. One such revolutionary approach is the Zelda cyclone milling, a cutting-edge method that has gained widespread recognition for its unparalleled effectiveness in treating metals and achieving high-precision results. This article delves into the intricacies of Zelda cyclone milling, exploring its underlying principles, operational skills, and the benefits it offers to the manufacturing sector.

Understanding the Principle of Zelda Cyclone Milling

At the heart of Zelda cyclone milling lies a unique cutting principle that capitalizes on the relative movement between the rotary crushing shot and the workpiece. The tool design is characterized by multiple cutting edges, strategically distributed around the tool to facilitate a smoother cutting process. Unlike traditional methods, the cyclone milling tool boasts a smaller advanced angle, which significantly reduces the cutting force during treatment, resulting in a more seamless processing experience.

The "cyclone effect" is the driving force behind this innovative technique. As the tool rotates, the cutting force is evenly distributed by centrifugal force, thereby minimizing the impact on the workpiece surface and reducing heat accumulation. This, in turn, leads to a decrease in tool wear and tear, ensuring a longer lifespan and enhanced precision. In high-speed machining, cyclone milling proves particularly effective in controlling thermal deformation, guaranteeing the integrity of the workpiece.

The Multifaceted Nature of Zelda Cyclone Milling

One of the standout features of cyclone milling is its versatility. By employing a combination of cutting and extrusion, this technique is not only suited for aircraft grinding but also excels in tackling complex three-dimensional contours and surfaces. Its adaptability makes it an ideal solution for supplementing intricate operations, including deep hole drilling, lateral processing, and groove treatment.

Mastering the Operational Skills of Zelda Cyclone Milling

To fully leverage the advantages of cyclone milling, it is essential to master specific operational skills:

- Selecting the Optimal Cutting Parameters: Adjusting the cutting speed, feed rate, and cutting depth is crucial. Excessive cutting speed can lead to overheating or premature wear, while insufficient speed can compromise treatment efficiency. Operators must carefully choose cutting parameters based on the workpiece material, tool characteristics, and machining requirements.

- Maintaining the Correct Contact Angle: The contact angle between the tool and workpiece has a direct impact on the processing outcome. Ensuring the cyclone milling tool is at an optimal angle on the workpiece surface is vital for achieving a uniform cutting effect, minimizing cutting forces, and reducing vibrations.

- Reasonable Control of Feed Rate: The feed rate directly affects the cutting force and surface quality. Adjusting the feed rate according to tool and workpiece characteristics prevents excessive cutting, which can compromise part quality.

- Utilizing Cooling Liquid: In high-load cutting operations, employing cooling fluid effectively reduces tool temperature, mitigating the effects of thermal expansion on precision. Cooling liquid also aids in chip removal, maintaining a clean processing area, and preventing tool clogging or damage.

- Regular Tool Condition Checks: To ensure processing quality and tool longevity, operators must regularly inspect tool wear. Replacing or reconditioning worn or damaged tools is essential for maintaining processing stability and precision.

The Benefits of Zelda Cyclone Milling in Modern Manufacturing

The incorporation of Zelda cyclone milling into modern manufacturing has yielded numerous benefits, including:

- Enhanced Precision: Cyclone milling’s unique cutting principle and controlled operational parameters enable the achievement of high-precision results, making it an ideal choice for complex and demanding applications.

- Improved Efficiency: By reducing cutting forces, vibrations, and heat accumulation, cyclone milling streamlines the processing experience, leading to increased productivity and reduced production time.

- Increased Tool Longevity: The minimized wear and tear on tools resulting from the cyclone effect and optimal operational skills contribute to extended tool lifespan, reducing maintenance costs and downtime.

- Versatility: The adaptability of cyclone milling to various applications, including complex contours and surfaces, makes it a valuable asset for manufacturers seeking to diversify their product offerings.

Conclusion

In the pursuit of innovation and excellence, the adoption of Zelda cyclone milling has revolutionized the manufacturing landscape. By grasping the underlying principles, mastering operational skills, and leveraging its multifaceted nature, manufacturers can unlock the full potential of this cutting-edge technique. As the demand for precision and efficiency continues to drive the industry forward, Zelda cyclone milling is poised to play an increasingly vital role in shaping the future of modern manufacturing.