Processes involving the use of machinery introduce typical irregularities in the product surface. The roughness of a product’s surface affects its durability and performance. Hence the need for surface finishing. Continued use often causes the product to wear out over time. This is usually due to high friction between the surface of the product and the surface it is used on. In contrast, a smooth surface with a surface treatment is more durable and has less or no friction.

1. What is surface finishing?

Surface finish is a parameter that determines the physical properties (appearance) of a part. It is a method of modifying the surface of a material through a process that adds, removes or reshapes the metal surface.

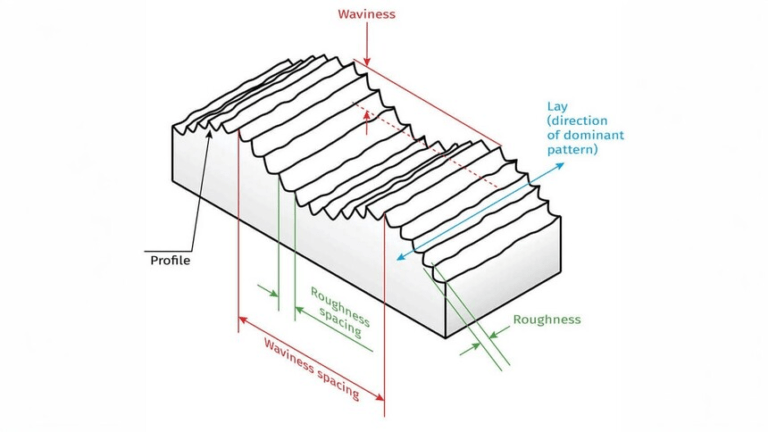

Surface finish can be defined by three main characteristics. These are surface roughness, waviness and rolling.

The measurement of total spatial irregularity on a metal surface is called surface roughness. It also describes the number of peaks and valleys on the surface. The lower the number, the fewer irregularities, which means less surface roughness and better surface finish. When professionals talk about surface finish, they usually mean “surface roughness.”

Surface finish measurements can also be expressed in terms of waviness. Ripple is caused by the deflection, curvature, or vibration of particles. Waviness can be measured if a surface has more space between irregularities than other surfaces.

2. Why is surface finish so important?

Surface treatment plays a key role in custom processing by determining how a product reacts to its environment. It is therefore crucial to evaluate the durability and effectiveness of the product during its use.

Surface finish affects many aspects of the ability of product components to resist wear. These include the ability to aid or destroy lubrication, increase or decrease friction with mating parts, and resist corrosion.

Different surface treatment methods have different effects on products. Surface treatment methods have the following functions:

Improves product durability by reducing friction.

It is essential for resistance to chemicals and corrosion.

It helps paints and paints adhere.

This gives the product a specific visual appeal.

Easily eliminates surface defects.

3. How to measure the roughness of a surface?

Measuring surface roughness involves calculating the relative smoothness of a product’s surface profile. It uses Ra as a numerical parameter.

As mentioned above, the three basic components of a surface are roughness, waviness, and blades. These components are crucial in the geometric properties of the surface.

There are several systems for measuring surface finish. These surface finish measurement systems include:

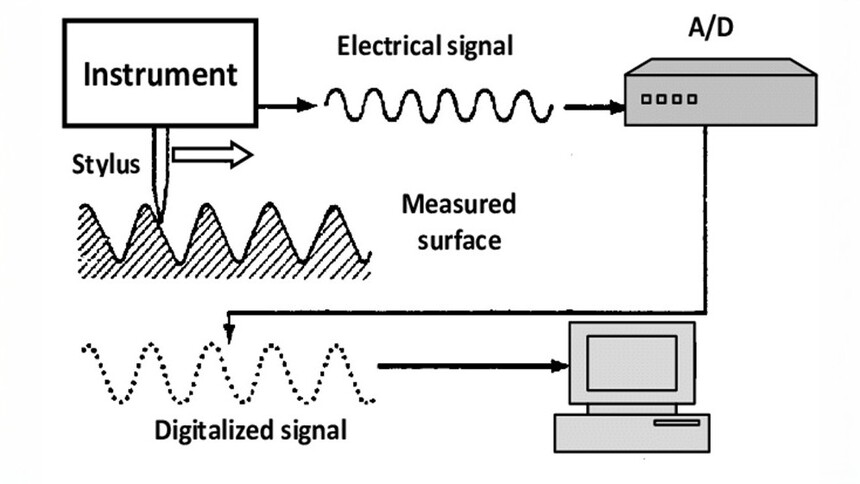

Contact method (pen probe instrument)

The contact method uses a stylus probe instrument to measure the surface condition of a product. First, the stylus is moved along the product surface, then the vertical movement of the stylus is recorded.

The recorded pen profile is then used to calculate the three basic surface roughness parameters. This method requires machine interruption and the pen tip may leave tiny scratches on the product surface.

In order to accurately measure the surface roughness of precision objects, you should ensure that the diameter of the stylus tip is as small as possible and the contact pressure on the surface is small.

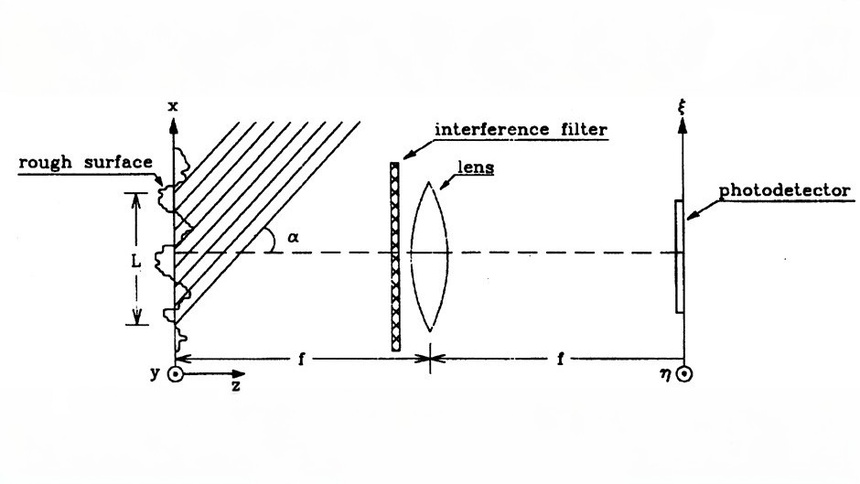

Non-contact methods (optical light, laser or x-rays)

The non-contact measurement method uses optical instruments such as X-rays and lasers instead of a stylus to measure the surface roughness without touching the product surface, and the measurement speed is fast.

Optical scattering or ultrasonic scattering is one of the most useful methods here. Optical instruments will send ultrasonic pulses to the surface of the product. This pulse changes, interferes and causes reflections in the instrument. You can now evaluate the reflected waves in the instrument to determine surface roughness parameters.

Microscopy techniques are also useful for examining microscopic peaks on the surface of materials. Again, these methods provide consistent results.

4. What are the factors that affect surface finish?

Type of coolant used

Using coolant is a great way to improve surface quality and tool life during machining. It effectively reduces surface friction. During the CNC machining process, heat will be generated, which will affect the physical properties of the surface and make it rough.

Using a high pressure coolant may well improve the surface finish, but it is not the most effective solution as it is not suitable for lower cutting speeds. Using the lowest grade coolant has been recognized as the most effective method of reducing surface roughness. This method is inexpensive, less polluting and offers good part performance. Additionally, it reduces tool wear and surface roughness.

Cutting parameters

During processing, surface finish is essential to product quality. However, achieving the desired surface finish depends on cutting parameters such as feed, depth of cut and cutting speed.

When cutting using CNC machine tools, increasing the cutting speed will reduce surface roughness. This means that the faster the cutting speed, the lower the surface roughness (assuming all other parameters remain constant).

As the cutting depth increases in CNC machining, the maximum roughness depth tends to increase. This only happens if other relevant parameters remain unchanged. Additionally, increasing the feed corresponds to a decrease in average roughness during CNC machining.

To improve machining processes, cutting fluids reduce surface roughness in all cutting processes. This is achieved by lowering the tool temperature, thereby reducing the coefficient of friction. However, fluid penetration into the cutting gap can also reduce tool and product adhesion.

Type of processing technology

The type of processing technology used in manufacturing the product determines the surface roughness of the product. The machining process is controlled by two main machining parameters, namely feed rate and cutting speed.

Cutting feeds and speeds used in metal machining processes, such as turning in CNC machining, have a large impact on the surface finish of the final product. The surface value increases with increasing feed, while the surface pattern roughness decreases with increasing cutting speed.

vibration

Unworn or worn tools can cause vibrations that can affect the surface finish of your product. As tools wear, they affect the integrity of the product’s surface finish, vibrating unpredictably to achieve a smoother surface.

The vibration frequencies and amplitudes obtained with uncarried tools influence the surface condition by adding simple sinusoidal vibrations. Vibrations have different amplitudes and frequencies, which means that the average roughness increases as the amplitude of the sine wave increases. Vibration frequency has minimal effect on surface roughness.

5. How to improve surface roughness

During the manufacturing process, there are several ways to improve the surface finish of a product, part or device. It is effective in reducing friction and extrusion between tool and workpiece. Other techniques include sharpening tool edges and ensuring certain materials are properly heat treated. In this way, machine tool vibrations can be reduced.

The most effective ways to improve surface roughness are:

Improve cutting conditions

Proper reduction of surface treatment is a key cutting condition in the production method. Some improvements in cutting conditions include: cutting materials at high speeds, reducing feed rates, using high quality cutting fluids, improving the rigidity of the processing system, and using cutting by ultrasonic vibrations.

Choose the right processing technology

The choice of excellent processing technology determines the surface finish of the product; on the contrary, incorrect or invalid treatment technology may affect the effectiveness and quality of treatment.

Choose the right raw materials

Some parts of equipment or machines are made of different materials, so the choice of different production methods or tools based on the density of different raw materials has a direct relationship with the surface finish.

Achieving the best possible surface finish is essential to product durability and effectiveness. It is therefore crucial to establish strict standards for surface finishing. This must be combined with a cost effective and correct method of producing the required surface finish.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.