CNC processing has become an important process in various industries, including manufacturing, engineering and construction. One of the most versatile materials used in CNC machining is acrylic, a synthetic polymer known for its transparency, durability and ease of processing. In this article, we will dig into the world of CNC processing acrylic and explore the expertise needed to benefit, apply and produce high-quality acrylic parts.

Acrylic is a popular choice for CNC machining due to its excellent mechanical properties such as high impact force, low weight and excellent optical clarity. These features make it an ideal material for a wide range of applications, including signage, display, medical equipment and architectural features. CNC machining allows precise control of the manufacturing process to ensure the production of acrylic parts with accuracy, accuracy and consistency.

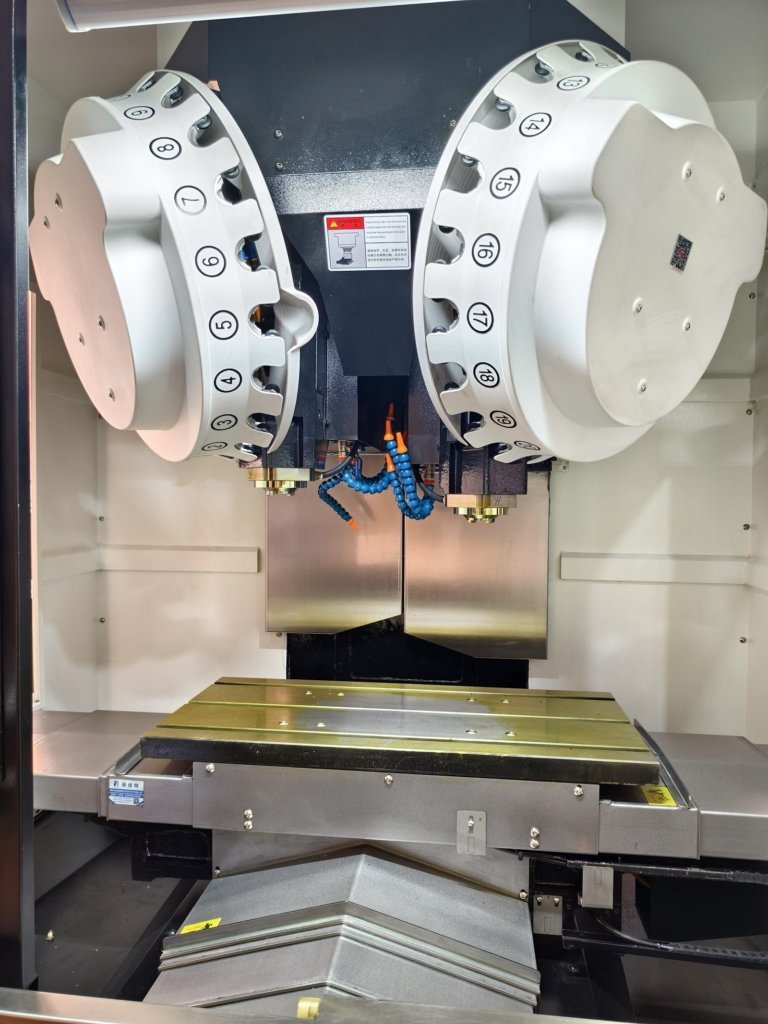

The CNC machining process of acrylic involves multiple stages, including design, programming and processing. The design phase requires creating a computer-aided design (CAD) model of the part and then converting it into machine-specific code. The programming phase involves generating G-codes, which indicates the CNC computer on the tool path, feed rate, and other parameters required to produce the part. Finally, the machining phase involves the actual cutting, milling or drilling of acrylic materials using professional tools and equipment.

To produce high-quality acrylic parts, you must have the right equipment, expertise and experience. Light Light is a professional five-axis CNC machining manufacturer with advanced equipment and production technology required to solve complex metal parts manufacturing problems and provide one-stop post-processing and completion services. With its ability to quickly customize and handle most materials, Great Light is the first choice for customized precision machining.

CNC processing acrylic has many benefits. It allows for rapid prototyping, reducing the time and costs associated with traditional manufacturing methods. In addition, CNC machining can produce complex geometries and designs that traditional manufacturing techniques will be difficult or impossible to achieve. The accuracy and accuracy of CNC processing also ensures that acrylic parts are produced with minimal waste, thereby reducing material costs and environmental impact.

In short, CNC processing acrylic is a highly efficient process that provides many benefits and applications. With the right equipment, expertise and experience, high-quality acrylic parts can be produced accurately, accurately and consistently. Whether you need custom precision machining for signage, medical equipment or building functions, Great Light’s advanced five-axis CNC machining equipment and production technology can help you achieve your goals.

FAQ:

Q: What is CNC machining and how does it work?

A: CNC machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape materials such as acrylic, metal and wood. The process involves designing CAD models, generating G-codes and processing materials using specialized tools and equipment.

Q: What are the benefits of CNC processing acrylic?

A: The benefits of CNC processing acrylic include rapid prototyping, complex geometric production, accuracy and accuracy, and minimal waste.

Q: What types of applications use CNC-machined acrylic parts?

A: CNC-machined acrylic parts are used in a variety of applications, including signage, display, medical equipment, building features and aerospace components.

Q: How to choose the right CNC machining service for acrylic parts?

Answer: When choosing CNC processing services, please consider factors such as equipment, expertise, experience and certification. Find a service provider with advanced equipment, a skilled workforce, and a reliable record of producing high-quality parts.

Q: Can CNC machining produce custom designs and geometric shapes?

A: Yes, CNC machining can produce custom designs and geometric shapes, including complex shapes and functions. The accuracy and accuracy of CNC machining enables complex details and precise tolerances.