Beyond Laugh: How CNC Meme Madness Reflects a True Manufacturing Genius (and How to Fix It)

If you spend any time in the processing world (online or off), you may stumble upon what is called a glorious phenomenon "CNC meme crazy." From operators who interact with the end mills of snapshots and mysterious tool crashes to engineers who deserve to be tolerant of expectations, these memes are digital coolant splashes for our industry. They are related, often interesting, and comforting. But under humor is a powerful truth: They highlight the real challenges and triumphs of precision manufacturing.

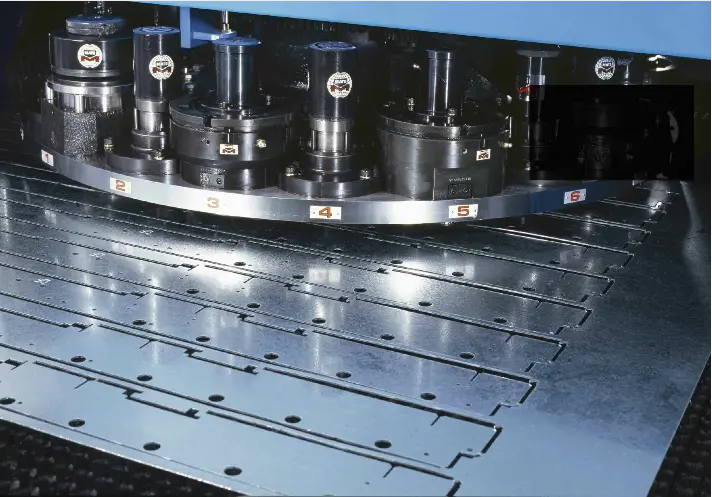

In Greatlight, we laugh and The community is because we’ve been there. We also see jokes about the core issues these memes represent – technical obstacles, time pressures, material qualities, the pursuit of perfection. Crucially, we have built the entire service solve Their peaks of using manufacturing technology: Advanced five-axis CNC machining.

Decode Crazy: Memes as Creating the Truth Taylor

Let’s break down some classic memes and discover what they say is realistic:

-

this "Set it again" nightmare: Template: Futurama Fry "Not sure if…" image Not sure if… Make another setup…or just accepting parts will never be tolerated.

- Reality: Complex geometry often requires multiple settings on a 3-axis machine. Each setting introduces potential human errors, fixed quality inaccuracy and tolerance stacks. The more settings are, the higher the chance waste climb rate and the timetable expands.

- Greglight Solution: 5-axis power. Machining complex curves, undercuts and contours at the same time from almost any angle? That was our bread and butter. A workpiece setup. Reduce processing errors. Closer total tolerances, as all key features are processed in a single unified coordinate system. this "Set it again" Memes become irrelevant.

-

Material Crash Memes: Template: Distracted Boyfriend girlfriend: High-speed steel. Distracted boyfriend: carbide. The girl stares: Mechanic melts, trying to cut inconel

- Reality: Exotic alloys (titanium, inconel, hardened tool steel) are engineering miracles, but can be processed nightmare. Their high strength, hardness and institutional trends quickly destroy tools, resulting in excess heat and resulting in dimensional instability, even without professional treatment.

- Greglight Solution: Professional knowledge + technology. We’re not just have 5-axis machines; we wave them with a deep scientific understanding of matter. We optimize tool routes, cutting speeds, feeding and cooling strategies specifically for challenging materials (usually using high-pressure coolant systems). Our rigid mechanism minimizes vibration, which is essential for hard metals. "Material crash" It is a challenge to accept and conquer every day.

-

this "Tolerance Temper": Template: Guy blinks and confused Graphic specifications: Tolerance +/- 0.0001" mechanic: … Visible chaos and sweating

- Reality: Sometimes design pushes the limits of productivity. Maintaining ultra-tight tolerances requires not only good equipment, but also special controls on temperature, vibration, tool deflection and machine calibration. Consistently mass-producing such parts is a real test.

- Greglight Solution: Engineering accuracy. Our workshops are a controlled environment. We invest in state-of-the-art 5-axis machines known for their rigidity, thermal stability and ultra-proprietary feedback systems. Coupled with strict metrology, using CMM and precise measurements, we achieve and Verify Those with challenging tolerance are reliable. We understand the language of micron.

- this "Endless engineering change orders (ECO)" legend: Template: SpongeBob SquarePants 5 hours later engineer: Make small design adjustments… Five hours later: The mechanic buried it under revised drawings and waste paper.

- Reality: Iteration is crucial, but slow and difficult to prototype. Effective processing of initial iteration can gradually fall into the entire development cycle, greatly increasing costs and time to market.

- Greglight Solution: Through technical agility. Five-axis machining is good at rapid prototyping of complex parts. The ability to quickly generate efficient tool paths for complex designs and accurately process them in a single setup greatly speeds up the iteration process. We are a smooth expansion of your R&D team, alleviating the pain of ECOS.

Why your partners oppose manufacturing "crazy"

We focus on Advanced five-axis CNC machining More than just having cool equipment. Here’s about strategic deployment techniques to address the core frustration captured in these viral memes:

- Solve complex geometric shapes: Multi-axis freedom can solve the angle and characteristics of smaller machines or inefficient features. Less settings for better accuracy.

- Master challenging materials: Precise control and expert technology ensure efficient processing of the strongest alloys.

- Achieve uncompromising accuracy: Stable platform and meticulous process provide consistent tolerances.

- Time to accelerate to the market: Faster setup, simultaneous multi-faceted machining and fast prototyping system functions keep the parts off the door and are verified faster.

- Provide a truly one-stop solution: From initial machining to critical post-treatment (fine finishing, heat treatment coordination, precise assembly, strict quality control), we manage the entire journey.

Customize your precision and conquer chaos

The next time you laugh in the CNC meme, remember the originality of driving the solution behind it. At Greatlight, we leverage the power of five-axis CNC machining not only to avoid traps and frustration, but also to unlock new possibilities in precision metal parts manufacturing.

Don’t let the manufacturing challenge be the focus of your next project. Bring us your most demanding designs, the trickiest materials and the most stressful tolerances. Let our technology and expertise change potential "Meme Crazy" Enter the story of manufacturing mastery and success.

Customize your precision parts now at the best prices! Contact Greatlight today for consultation and learn how we can turn complex challenges into perfect reality.

Conclusion: More than just memes – build the future precisely

CNC Meme Madness is more than just internet humor. It is an original, shared language that expresses the experiments and triumphs that bring complex designs into metal. It highlights the real pressures of time, accuracy, complexity and material limitations. At Greatlight, we made a joke because we implemented the solution. We have invested relentlessly in the transformational power of advanced five-axis CNC machining, not as a gi-header, but as a fundamental technology designed to eliminate these common frustrations. Through crashed settings, taming exotic alloys, achieving submicron accuracy, and accelerating the innovation cycle, we took the initiative to solve the problem of promoting memes.

Our mission is clear: transforming potential nightmare into seamless success stories that provide complex mission-critical parts with unparalleled efficiency and quality. This is how we move beyond laughter, drive tangible value and realize next generation innovations – one precisely processed component at a time. Choose Greatlight and choose painless accuracy.

FAQ: Greglight CNC Precision Processing Service

Q1: What exactly is 5-axis CNC machining and why is it better?

A: Unlike traditional 3-axis machines (moving tools along X, Y and Z axes), 5-axis machines can also rotate workpieces (A and B axes) or tool heads. This allows machining of incredibly complex shapes, contours and angles In a setting. Benefits include excellent accuracy (small tolerance stacking), faster production times, reduced processing/error, and the ability to produce geometry that is simply impossible.

Q2: Can Greatlight really process any metal?

A: Although no one Literally machine all Metal, Greatlight specializes in a large number of Commonly used and challenging materials. This includes, but is not limited to:

- Aluminum alloy (For example, 6061, 7075)

- Stainless steel (e.g. 303, 304, 316, 17-4 pH)

- Tool Steel

- Titanium alloy (For example, ti-6al-4v)

- Nickel alloys (Superalloys) (For example, Inconel 625, 718)

- Copper and brass

- Plastics (engineering grade) (e.g., Peek, Uhmw, Derrin)

We recommend about manufacturing your Specific materials and designs.

Q3: What kind of tolerance can be maintained consistently?

A: Tolerances depend to a large extent on the part size, geometry, material and volume. However, with our advanced 5-axis equipment and strict process controls, we usually implement and implement extremely Tensional tolerancesoften downward +/- 0.0002" (+/- 0.005mm) or better On the key functions of appropriately sized parts. We utilize accurate CMM checks to verify consistency.

Question 4: Do you provide completion and other post-processing services?

one: Absolutely! We provide comprehensive One-stop organization service:

- Deburring & Surface Finishing: Manual, tumbling, vibrating finish.

- Heat treatment: Coordinate with qualified partners to anneale, relieve stress, harden and cool down.

- Plating and coating: Anodized (type II, III), electroplating (nickel, chromium, zinc), passivation, powder coating.

- Precise grinding

- Silk screening, laser marking, engraving

- Assembly and kit

Discuss your requirements and we will manage the complete process.

Q5: How fast is it "Quickly" Used for custom parts?

A: Delivery times vary greatly depending on part complexity, quantity, material availability and required finishes. However, our 5-axis efficiency, internal functionality minimizes outsourcing latency, and an optimized workflow allows us to provide a lot of Faster turnaround time Compared to stores that rely on multiple settings or outdated devices. We specialize in research Rapid prototyping and Low to medium volume generation. Contact us for accurate quotes and schedules.

Q6: What file format do I need to provide?

A: We prefer 3D CAD files In standard format Steps (.stp, .step), iges (.igs, .iges) or parasolid (.x_t, .x_b). 2D drawings (PDF or DWG/DXF) The content with critical dimensions and tolerances is also essential for a complete understanding. Our engineers can review and recommend.

Question 7: What makes Greatlight different from other 5-axis CNC stores?

A: In addition to having advanced equipment, our Competitive Advantage From:

- Deep technical expertise: Solve complex manufacturing challenges in different industries.

- End-to-end service: Handle everything from raw material procurement to final finished parts/assemblies.

- Constantly pay attention to quality: Accuracy is not only a goal; it is deeply rooted in our process control and quality inspections.

- Agile and Partnership: Act as a responsive extension for your prototype and production team.

- Value Project: Provide advice to optimize your design for productivity and cost-effectiveness without compromise.

Question 8: How do I start with a custom CNC machining project?

Answer: It’s very simple!

- Contact Us: Visit our website or use our engineering contact portal ([provide link or instructions if applicable]).

- Provide details: Upload your CAD files, drawings and specifications (materials, quantity, tolerances, finishes, etc.).

- consult: Our engineers review your design and may contact you for clarification or optimization suggestions.

- Quote: We provide detailed competitive quotes including pricing, lead time and manufacturing insights.

- Production and delivery: Upon approval, we initiate precise manufacturing and reliably deliver your finished parts.