CNC’s Outstanding Journey: From Fist to Unparalleled Accuracy

The manufacturing world relies on precision, efficiency and innovation. The core of this evolution is Computer Numerical Control (CNC) Processing – A technology that converts raw materials into complex components with amazing accuracy. Its journey spans over 70 years and reflects the leap from analog simplicity to digital mastery. Let’s explore how CNC has evolved and revolutionized how we build everything from spacecraft to smartphones.

Genesis: NC Machines and Fist (1940s-1950s)

The precursor of CNC, Numerical Control (NC)appeared after World War II. The U.S. Air Force seeks consistent aircraft parts, funded MIT’s 1949 project, connecting milling machines to computers through Punched paper tape. These tapes, physical reels with holes of binary code ("0s" and "1s"), directional machine. The operator spent hours encoding the tape for basic cutting. Like a machine Cincinnati Hydropower Machine (1950) proved this concept, but was prone to errors and could not adjust the mid-term process. Debugging means restarting the tape – a tedious bottleneck.

Computational power is under control: The Dawn of True CNC (1960s to 1970s)

Used in the 1960s Direct computer link. John T. Parsons and Servo Laboratory at MIT A groundbreaking integration Microcomputer (e.g. PDP-8). This allows instructions to be digitally stored, electronically edited and reused. G codea common programming language for toolpath commands, became the standard. Early CNC machines were expensive ($500,000+) and were limited to aerospace/defense only. But, they were born Three-axis millingenable curves and angles before not being implemented.

Democratizing Microprocessors CNC (1980s)

1980s Microprocessor revolution Reduce computers and cut costs. ICs replace mainframes, making CNC suitable for the automotive and tool industries. Programmable Logic Controller (PLC) Automated tool replacement and coolant system. Fanuc and Siemens Appears as a control system giant, and software advancements enable Canned cycle (Pre-programmed routines for drilling/boring). CNC transitions from niche to mainstream, although it still requires manual programming by skilled operators.

CAD/CAM Integration: Digital LEAP (1990s)

The 1990s Joint CNC and Computer Aided Design (CAD) and Computer-Aided Manufacturing (CAM). Engineers can now:

- Design 3D models in CAD software.

- Use CAM to automatically generate tool paths and G code.

- Simulate machining to detect errors.

This eliminates manual coding, reducing waste and complex geometry. Multitasking computer Combined with milling, rotation and grinding, improve efficiency. Windows-based controls Make the interface friendly and further accelerate adoption.

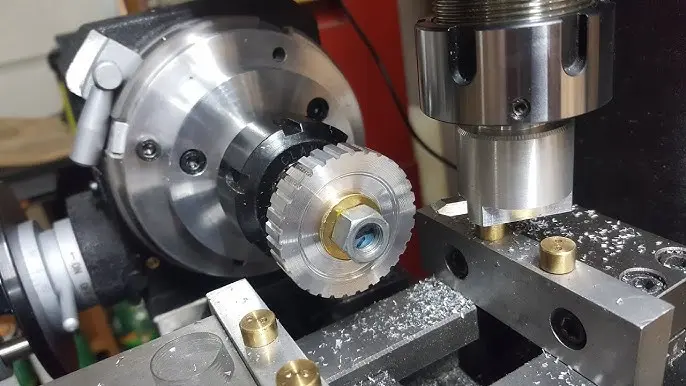

21st Century: High-speed, multi-axis and intelligent machining

Modern CNCs combine physical precision with digital intelligence:

- 5-axis machining: Parts rotate on multiple planes in one setup to achieve aerodynamic turbine blades or biomedical implants.

- High-speed machining (HSM): Advanced tool paths and spindles (rpm above 50,000) with high-quality finishes faster.

- IoT and Industry 4.0: The machine monitors wear through sensors, optimizes tool paths through AI, and synchronizes with the factory network for predictive maintenance.

- Nano Accuracy: Laser calibration and real-time compensation can achieve tolerances in 5 microns of optical or semiconductor.

CNC no longer "only" Cut metal; this is a data-driven ecosystem driving field such as electric cars and space tourism.

Greglight CNC: Where History Is a Climax Manufacturing Industry

exist Greglight CNC machiningWe use this legacy to solve the toughest manufacturing challenges today. As Professional five-axis CNC machining expertwe combine Advanced equipment and Proprietary production technology deliver:

- Complex metal parts: Processed aerospace alloys, titanium or hardened steel with ±0.005mm tolerance.

- One-stop organization: Anode, polish, paint and assembly under a roof.

- Rapid prototyping complete production: Fast turnaround without sacrificing accuracy.

- Material versatility: Expertise in over 50 metals, plastics and composites.

Why choose Greatlight?

Whether it’s a turbocharger housing or a surgical tool, our five-axis capability ensures unparalleled accuracy. We are not just suppliers; we are partners committed to making precise access. Custom parts at industry-leading speed and price – Contact CNC today’s quotes.

Conclusion: Unlimited accuracy

From holes in paper to AI-driven systems, the evolution of CNC is a testament to engineering creativity. Originally to address the solutions of wartime manufacturing, it is now the foundation of global innovation, and authorized design was once considered impossible. With the merger of AI and additive manufacturing with CNC, the future is expected to be more synergistic: self-optimized factories, hybrid 3D printed/processed parts, and sustainable micro-systems. However, the core task remains the same: transforming imagination into tangible perfection.

FAQ (FAQ)

Q1: What is the key difference between NC and CNC machines?

NC uses pre-programming Punching tape No real-time calculations. CNC use Digital controls and softwarerealize direct adjustment, complex geometry and automation.

Q2: Why is 5-axis CNC machining higher than 3-axis?

5-axis machining allows simultaneous movement Five axesreduce settings and handle complex curves in one operation. This can improve the accuracy of contoured parts such as impellers and cut production time by 60-70%.

Question 3: Can any material be used in CNC machines?

Modern CNC systems can handle almost any material: aluminum, steel, titanium, ceramic, plastic and composite materials. Tools and processing parameters are adjusted accordingly by experts such as Greatlime.

Q4: How to change CNC manufacturing in CAD/CAM?

CAD/CAM automation Design-to-production workfloweliminate manual G code generation. This reduces human error, seeds prototypes, and enables impossible complex 3D contours through manual programming.

Q5: What makes modern CNC "Smart"?

and IoT sensors and AI Allows real-time monitoring of tool wear, vibration and temperature. The machine automatically corrects deviations and predicts failures, thus minimizing downtime.

Question 6: Why choose a five-axis expert like Greatlime?

Five-axis expertise ensures lower tolerances, reduces part handling and faster complex design completion. We’ll use it with End-to-end service– Mobile phone, completion and inspection – guarantees production parts without third-party delays.