As a leading provider of Gloucester CNC machining services, experts in this field understand the importance of accuracy and accuracy in manufacturing high-quality parts. With the advancement of technology, machining of computer numerical control (CNC) has become a key aspect of modern manufacturing, allowing the creation of complex geometries and precise tolerances. In this article, we will dig into the world of CNC Gloucester experts, exploring their capabilities, services and the benefits they offer to industries that require customized precision machining.

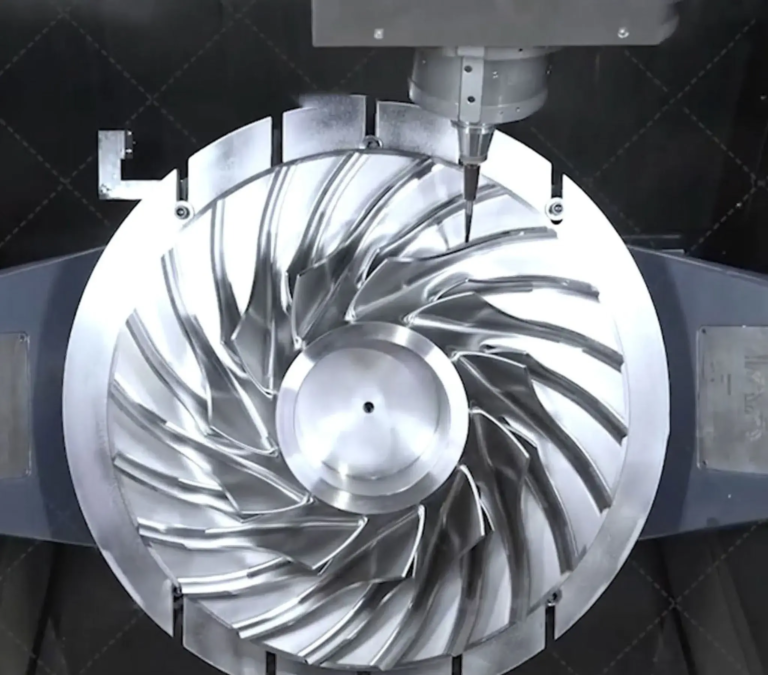

CNC machining involves the use of computer-controlled machines to manufacture parts of various materials, including metals, plastics and composites. The process begins with the design of the part and then converts it into a digital format that the CNC machine can understand. The machine reads the design and executes instructions to cut and shape materials with high precision and speed. This technology revolutionized manufacturing, enabling the production of complex parts with tight tolerances and high surface finishes.

One of the key benefits of CNC machining is its ability to have high precision and repeatability parts. Using a computer-controlled machine ensures that each section is the same and that it is very small in deviation from the design specifications. This is especially important in industries such as driving, automotive and medical equipment where accuracy and reliability are crucial. Furthermore, CNC machining allows the creation of complex geometric shapes and shapes that are difficult to produce using traditional manufacturing methods.

At Gloucester, CNC machining experts provide a range of services including milling, turning, drilling and grinding. These services can be tailored to meet the specific needs of each customer, from prototype development to production runs. With advanced equipment and technology, CNC Gloucester experts can use a wide range of materials including aluminum, steel, titanium and plastics. They also offer a variety of finishing services such as anodization, chrome plating and laser engraving to enhance the appearance and performance of the parts.

CNC Gloucester experts are the first choice for many industries when it comes to custom precision machining. Their expertise and experience enable them to deliver high-quality parts with tight tolerances and fast turnaround times. From simple components to complex components, they can make parts that meet customers’ strict standards. CNC Gloucester experts focus on quality, reliability and customer satisfaction and have established themselves as trusted partners in manufacturing.

In short, CNC Gloucester experts offer a range of services and features that meet a variety of needs in industries that require customized precision machining. With their advanced equipment, technology and expertise, they can produce high-quality parts with precision, accuracy and speed. Whether you need prototype development, production runs or specialized finishing services, CNC Gloucester experts are ideal for manufacturing needs.

FAQ:

Q: What is CNC machining and how does it work?

A: CNC machining involves the use of computer-controlled machines to manufacture parts of various materials. The process begins with the design of the part and then converts it into a digital format that the CNC machine can understand.

Q: What are the benefits of CNC processing?

A: The benefits of CNC machining include high accuracy and repeatability, the ability to produce complex geometric shapes and shapes, and the ability to quickly produce time.

Q: What services do CNC Gloucester experts provide?

A: CNC Gloucester experts offer a range of services including milling, turning, drilling and grinding, as well as a variety of completion services such as anodizing, chrome plating and laser engraving.

Q: What materials can CNC Gloucester experts use?

A: CNC Gloucester experts can use a variety of materials including aluminum, steel, titanium and plastics.

Q: How to choose the right CNC processing service for my needs?

A: When choosing a CNC machining service, consider factors such as their expertise, equipment and experience, as well as their ability to meet your specific needs and deadlines.