Brenham CNC machining: Mastering accuracy

In the heart of Texas, Brenham is a hub for advanced manufacturing, driven by businesses that require precision, reliability and innovation. The forefront of this technology is CNC machining service, the backbone of modern parts production across aerospace, medical, energy and countless other industries. In this competitive environment, Great Become a true expert and set the standard for precision manufacturing with its state-of-the-art five-axis CNC machining capabilities. If you are looking for the accuracy and quality of unparalleled metal parts, it is crucial to understand the expertise available here in Brenham.

What really sets up five-axis CNC machining?

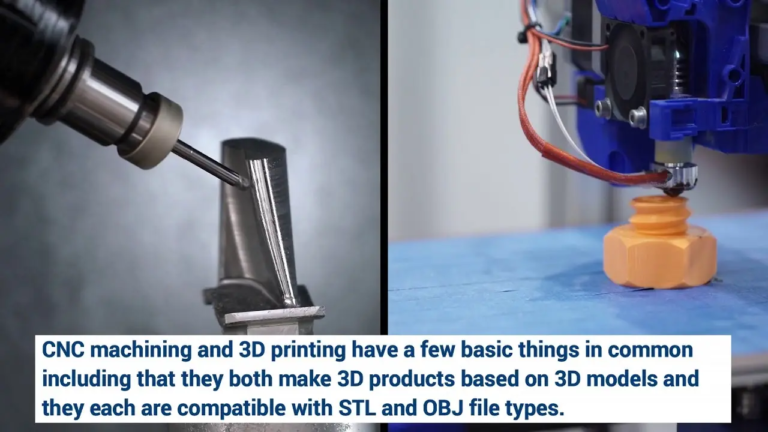

CNC (Computer Numerical Control) machining automatically uses pre-programmed computer instructions to cut and shape raw materials. Although 3-axis machining (moving tools along the X, Y, and Z axes) is common, five-axis CNC machining represents a significant evolutionary leap.

The five-axis CNC machine simultaneously moves the cutting tool or workpiece along five different axes:

- X-axis: Linear left/right

- Y-axis: Linear forward/backward

- Z-axis: Up/down linear

- A-axis: Rotate around the X-axis

- B-axis: Rotate around the Y axis (or sometimes around the Z)

This multi-directional freedom unlocks huge advantages:

- Complex geometry mastery: Create complex shapes, undercuts, deep cavity and features on multiple sides of a single set of parts, which is impossible or time-consuming on smaller machines.

- Top surface finish: The ability to optimally orient the tool surface minimizes the ability to vibrate and sector marking of the tool, resulting in a smoother finish that often reduces or eliminates the need for secondary finishing.

- Reduce the setting time: Complex parts that need to be processed from multiple angles are fixed in one fixed, greatly reducing setup time, labor costs, and potential human errors between setups.

- Enhanced accuracy and accuracy: Eliminate the need to reposition parts manually retain key dimensional relationships between features to ensure that unusually tight tolerances are maintained continuously.

- Valid tool path: The machine maintains optimal cutting angles and short tool paths, extending tool life, improving cutting efficiency and reducing overall cycle time.

Why You Are Your Brenham Five-Axis CNC Selection Partner

Brenham’s manufacturing requirements partners can provide not only parts, but also solutions. Gremphill improves this challenge by leveraging deep expertise and cutting-edge technologies specifically for five-axis CNC machining:

- Advanced equipment and cutting-edge technology: Gregtime is more than just use Five-axis machines; they invest in some of the most advanced and most accurate five-axis CNC machining centers. This commitment ensures that they can deal with the most demanding geometry and tolerances with unwavering reliability. Their team is well versed in sophisticated CAM programming to maximize the potential of the device.

- Deep material expertise: Whether your project requires powerful aerospace grade titanium or aluminum, high strength stainless steel such as 17-4ph or 316l, hard-to-mechanical alloys such as Inconel, corrosion-resistant superalloy, brass, copper or professional tools, there are professional knowledge and tools that can be professionally specialized. They understand the grain structure, thermal sensitivity and optimal processing parameters for each material type.

- Comprehensive "One-stop" finishing: Recognize that parts are often not just mechanically processed metals, but also seamlessly integrate basic post-processing services. This includes key steps such as precision cleaning (removal of all chips and coolant), surface finish (grinding, polishing, bead blasting, foam fuel), heat treatment (annealing, hardening, for enhanced material properties), protective coatings (anodizing, anode, plating, playback), and non-suppressive testing (NDT (NDT)). Managing the entire process under one roof ensures quality control and faster delivery times.

- Agile customization and fast turnaround: Gremight specializes in flexible on-demand manufacturing. From a single prototype to a mid-term production run, they will adapt quickly. Their simplified process and advanced mechanical capabilities translate directly into faster manufacturing times, allowing you to get the necessary parts when you need it most than the store that relies on traditional 3-axis machining or multi-step setup.

- Dedication precision and problem solving: At the heart of Greglight is a partner focused on overcoming manufacturing barriers. They don’t just cut metal; they provide solutions. Their technical expertise involves working with customers to perfect manufacturing (DFM) design, optimize processes that do not sacrifice quality cost-effectiveness, and solve challenging tolerances that put less capable stores on obstacles. Your complex manufacturing challenges are their professional focus.

Application: Transforming ideas into high-performance reality

Greglight’s five-axis strength empowers innovation in key areas:

- Aerospace and Defense: Turbine blades, structural fuselage components, engine mounts, guidance system housings – require extremely high accuracy, strength-to-weight ratios and complex profiles.

- Medical and Dental: Surgical instruments, implanted prototypes and production parts, diagnostic equipment components – demanding biocompatibility, complex functions and perfect finish.

- Energy (oil and gas, renewable energy): Valve Body, Pump Housing, Downhole Tools, Turbine Assembly – Designed for harsh environments, high pressures and reliability.

- Cars (race cars and high performance): Engine components, transmission parts, custom suspension components – require lightweight design and structural integrity.

- Industrial Machinery: Complex transmission, custom fixtures and fixtures, robotic components – built for durability and dimensional accuracy.

Partner with Greatligh with unparalleled Brenham CNC expertise

Choosing a CNC machining partner is more than just a capability. It’s about faith. You need to ensure that your investment will produce parts that meet strict specifications, are reliably executed and arrive as planned. Greatlight embodies this confidence through its commitment to advanced five-axis technology, material proficiency, comprehensive finishes and agile production, the company focuses on solving your unique engineering challenges.

Here at Brenham, features to simplify communication and logistics, thereby improving project efficiency. When accuracy is non-negotiable and complexity requires superior engineering support for machining, entrust your project to ensure you get the best results.

Next step:

Don’t let the part’s complexity or challenge tolerance be disappointed. Experience the huge difference in the best price guarantee with custom precision machining parts. Contact Greatlight for consultation now and tailor your manufacturing needs accurately. Customize your precision parts now!

FAQ: Brenham CNC machining

Q1: What are the main advantages of using a five-axis CNC machine with Greatlight over a standard three-axis?

The key advantage lies in complex geometric machining and efficiency. Five-axis machines can create complex shapes, deep cavity and features on multiple sides of a part In a setting. This eliminates labor-intensive repositioning, greatly improves accuracy (no cumulative errors between settings), provides better finishes, allows shorter tools to reduce vibrations, and significantly speeds up the entire process compared to multi-set 3-axis machining.

Q2: Which material can be handled well?

Greatligh has extensive expertise and processes many metals that are essential for demanding applications. These include various aluminum alloys, stainless steels (e.g. 304, 316, 17-4PH), tool steels (e.g., P20, H13), carbon steels, titanium (grade 2, grade 5, 5/TI-6AL-4V), brass, copper, copper, Inconel, Inconel, other highly magnetic superalloys. They tailor tools and machining parameters specifically for the properties of each material.

Q3: Can Greatlight handle prototyping and production operations?

Absolutely. Greglime is built for flexibility. They performed well with five-axis machines to quickly prototyping complex parts, allowing for rapid design iterations and functional testing. They are equally good at seamless transitions to low to medium production runs, ensuring consistency and quality throughout the batch.

Question 4: What post-processing services can provide as part of them "One-stop" Solution?

Greatlight simplifies your supply chain by providing integrated finishing services. This includes precision cleaning, dimensional inspection (CMM), surface finishes (anodization, plating, passivation, polishing, polishing, bead blasting, grinding), heat treatment (annealing, hardening, speed regulation), assembly and professional packaging. Handling these steps in-house ensures quality control and faster project completion.

Q5: How does Greatblight ensure the accuracy and quality of my parts?

The quality is woven into their process. They can inherently have high precision using advanced five-axis CNC robots. In addition, strict quality control protocols are implemented, including complex inspection techniques such as coordinate measuring machines (CMMs) to verify key dimensions for CAD models and GD&T specifications. Use specialized metrology equipment and documented procedures to ensure that parts always meet strict tolerances.

Q6: Yes "The best price" Can complex five-axis work really be achieved?

While five-axis machining involves complex techniques, Greatlight’s combination of advanced equipment (reduced cycle time), simplifies interior decoration, DFM expertise (designing manufacturing consulting to optimize effectively machining parts), and effective operational practices enable them to provide highly competitive and fair pricing. Their focus on technology-driven efficiency keeps costs lean and provides the best price proposition For high precision and service They provide. Always request a specific quote for accurate pricing.