Nowadays, CNC spark machines are widely used. The shaking function is the most important function of CNC spark machines. It is very effective in reducing processing time and obtaining a good surface. However, not all factories use the shaking function correctly. The main reason is that designers do not want to reduce the size of the electrodes enough and fear that too large a size will reduce accuracy. If we understand enough about electrode size reduction and agitation, we can use appropriate electrode size reduction to significantly improve the treatment efficiency.

01

Reduction in electrode size

(1) The concept of reducing the size of the electrodes

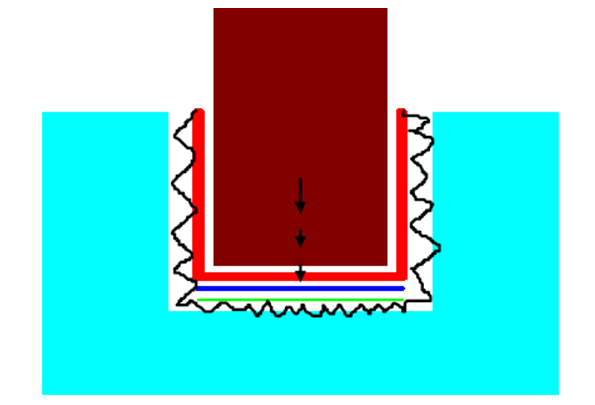

There is a spark gap during EDM machining, which is why the electrode must be smaller than the shape to be machined. The reduced value is called electrode size reduction.

Electrode size reduction R=(cavity size-electrode size)÷2

Schematic diagram of electrode size reduction

(2) The amount of electrode size reduction determines the treatment speed

The energy of EDM machining is large, the processing speed will be fast, and the discharge gap will be large. If the reduction in electrode size is increased, the processing speed (removal rate) can be increased several times. Another important point is that the roughing conditions are not only fast but also low in losses. This means that if the electrode size is small enough, efficient, low-loss conditions can be used.

The amount of electrode size reduction determines the speed

02

How to achieve good surface quality

The surface quality of rough machining is very rough, but we hope to get good surface quality in a short time. The best way to accomplish this is to use roughing conditions to machine the stock, then use finishing conditions to machine the surface.

Additionally, to reduce processing time, processing conditions should be changed at appropriate times. For example, if you start roughing with a maximum roughness of 40 µm and achieve a roughness of 5 µm, then you must have several steps between roughing and finishing to change the machining conditions.

(1) Bottom surface

The bottom surface can be achieved by changing the conditions and adjusting the height. But the side surface cannot be made because the discharge space of rough machining is larger than that of fine machining.

Bottom treatment

(2) Shake to obtain secondary treatment

To machine the side, the electrode must be close to the side.

Treatment of the bottom and sides

Movement in a plane perpendicular to the machining direction is called rocking, and the purpose of rocking is to complete lateral processing.

Agitation and Processing Directorate

03

Effect of two-dimensional shaking on accuracy

(1) Shape after stirring

We first need to understand the shape after shaking treatment. If the electrode is shaken into a certain shape, each part of the electrode should be shaken into the same shape, and then the outer shape of the electrode is drawn. The outer shape of the figure is the shape after finishing. This method can be used on any type of stirring form, providing an effective method for determining the treatment form.

Some shaking can lead to imprecise shapes, but generally speaking the error is not very large. We must have sufficient understanding of it. Let’s start with the vibration analysis of two-dimensional shapes.

Each part of the electrode follows the same shape when shaken

(2) Circular shaking

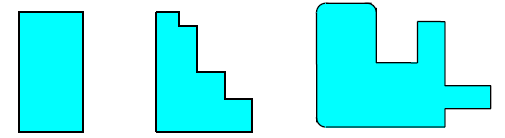

The electrode will be a little smaller than the actual desired shape in each dimension, so to achieve the desired shape and size it is necessary to enlarge the size by one R in each direction. Expanding an R in all directions is equivalent to making a circular motion of R at each point. The image below shows that straight parts are okay, but sharp corners are not enough.

For a general shape, as shown in the figure below, reducing the electrode size makes the outer corner radius smaller and the inner corner radius larger. This distortion is like a graphical shift. After using circular stirring, the processed shape will be correct. If you are using CNC or wire cutting to make electrodes and using offset to determine electrode size reduction, circular agitation creates the correct shape without sharp corners.

Another important point is that circular shaking is the standard shaking method, without overcutting. If you don’t know much about stirring, it is recommended to choose this stirring method.

(3) Square shake

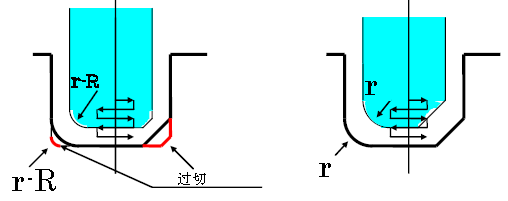

For EDM, corner processing is one of the most important processing. If the cavity itself is square or rectangular, as shown in the figure below, square stirring is preferable to circular stirring. At present, the processing efficiency of square translation is higher than that of circular translation.

But there is a problem if you also use square panning for general shapes. For example, in the image below, if you use a square shake, the diagonal area will be overcut. The most obvious error is at the 45° angle.

Part of the diagonal is overcut by square translation

04

Effect of three-dimensional shaking on accuracy

The effect of three-dimensional shaking on size can be referred to the two-dimensional plane XY YZ or ZX.

3D electrodes

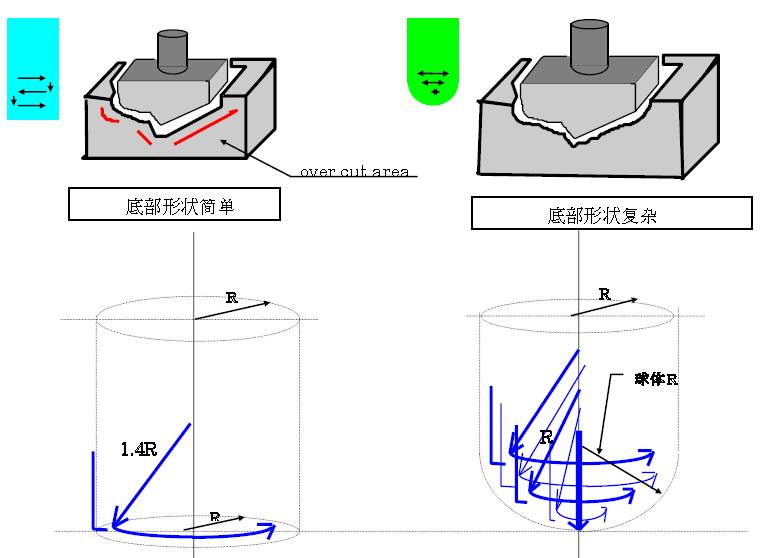

(1) Simple lower form

For general CNC EDM machines, the shaking value is constant from top to bottom (this method is called “bottom simple form”). If the XY plane is a circular translation, the XZ or YZ plane is the same as a square shake. This means that the bottom radius and the bottom slope are the same. Usually, due to the processing shift of R, the bottom radius and slope become smaller. If you use an electrode with a simple bottom shape, the sharp corners at the bottom will be cut too much. The overcut value should be determined based on the electrode ratio R. For this reason, rough machining is prone to overcuts.

For 3D electrodes, if you want to use a simple bottom shape pattern, the bottom corner radius and slope of your electrode should be consistent with the final shape.

2) Complex shape at the bottom

As shown in the picture above, it is difficult to determine the bottom radius of some electrodes, or sometimes the bottom of the electrode is not flat. There is no way these electrodes will do what is mentioned above. The “lower complex shape” (spherical translation) 3D mode solves this problem.

The typical way is: complex shape at the bottom. This looks like a circular translation from the side (ZX or YZ plane). There are no overcut areas. This method is also suitable for rough machining if large electrodes are used.

Simple background shape and complex background shape

05

in conclusion

(1) A suitable R, as large as possible, can significantly reduce the processing time.

(2) Basically circular stirring should be used because it has the same R value in all directions. Circular stirring is the safest way.

(3) Choosing square cladding will result in overcutting on sharp corners and beveled edges and is only suitable for rectangular shapes.

(4) Two-dimensional shaking of simple shapes, using circular shaking, its XY plane is circular, but XZ and YZ are square shaking, so complex shapes at the bottom will also cause overcutting.

(5) Based on the principle that circular stirring is the safest, using three-dimensional spherical stirring, it is circular stirring in all directions, so it is safe in three dimensions.

(6) For complex cavities with high precision requirements, you should choose three-dimensional spherical stirring; For most electrical discharge machining, the general choice of two-dimensional circular translation can meet the requirements, and it is easier to obtain better finish and higher efficiency than three-dimensional spherical shaking.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.