Production efficiency and machining precision are important competitive factors in the machine tool industry. However, rapid changes in machine tool processing conditions pose challenges to improve production efficiency and processing precision. When processing parts, small batch production should be carried out with high economic efficiency and high precision. In the aerospace industry, high material removal capabilities are required for roughing, while high precision is required for finishing. When processing high-quality molds, large quantities of material must be removed during roughing and high surface quality is required during finishing. At the same time, if it is necessary to achieve the minimum spacing of processing paths within a certain processing time, the machine tool must have a sufficiently high processing feed rate.

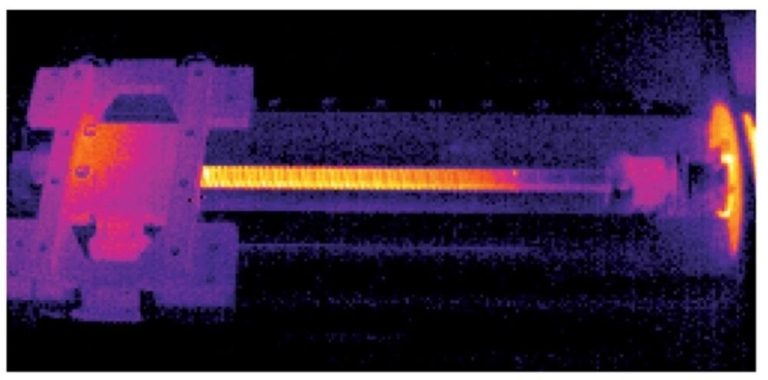

Figure 1 The heating situation of the ball screw during multiple reciprocating movements at a feed speed of 10m/min, 25℃ (purple) ~ 40℃ (yellow)

The thermal stability of machine tools plays an increasingly important role in the rapid changes of their processing conditions. In particular, small batch production faces the challenge of constantly changing processing tasks and inaccessible thermal stability conditions. Constant changes in drilling, roughing and finishing operations also subject machine tool temperature conditions to changing conditions. When roughing, the cutting rate increases to over 80%, while when finishing, it is less than 10%. Increasing cutting speeds and feeds cause linear drive ball screws to heat up. Therefore, the position detection technology of the feed drive plays a very critical role in the thermal stability of machine tools.

Avoiding part size deviations due to machine tool heat is a topic that the machine tool industry faces. Active cooling, symmetrical machine tool structures and temperature measurement technology are widely used.

The temperature change of the machine tool is mainly caused by the ball screw of the feed axis. The temperature distribution along the ball screw is closely related to the feed speed and driving force. On machine tools that do not use linear encoders, changes in screw length due to temperature can cause serious defects in the part. In principle, a ball screw and a rotary encoder installed on the screw can be used for NC feed axis position detection, or a linear array ruler can be used for detection.

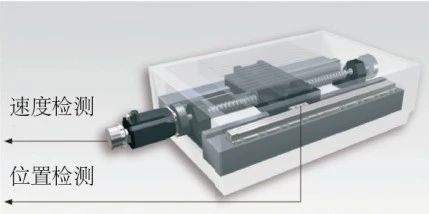

If the carriage position is detected using a screw thread and a rotary encoder, the ball screw must perform two tasks. As a drive system, it must transmit a large driving force, but as a measuring device, it is hoped that it can provide high precision position values and repeatable step values, but it does not There is only one rotary encoder on the position control ring. . Since wear or temperature changes in the drive mechanism cannot be compensated for, this structure is called semi-closed loop control. There are unavoidable positioning errors in the driving system, which seriously affect the quality of the workpiece.

Figure 2 Semi-closed loop position feedback control

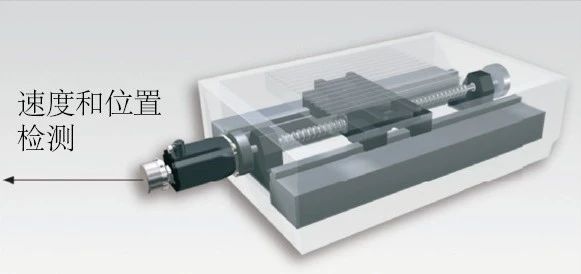

Figure 3 Fully closed loop position feedback control

If a linear encoder is used to sense the carriage position, the position control loop includes the entire feed mechanism, which is why it is also called fully closed loop control. Then the backlash and transmission error of the machine tool drive components no longer affects the position detection accuracy, and its accuracy almost solely depends on the accuracy of the linear scale and position of the machine tool. ‘facility. The basic situation of linear axes and rotary axes is the same. Position detection is carried out via a motor rotary encoder installed on the reduction housing or a higher precision angle encoder directly connected to the rotary axis. If an angle encoder is used, higher accuracy and repeatability can be achieved.

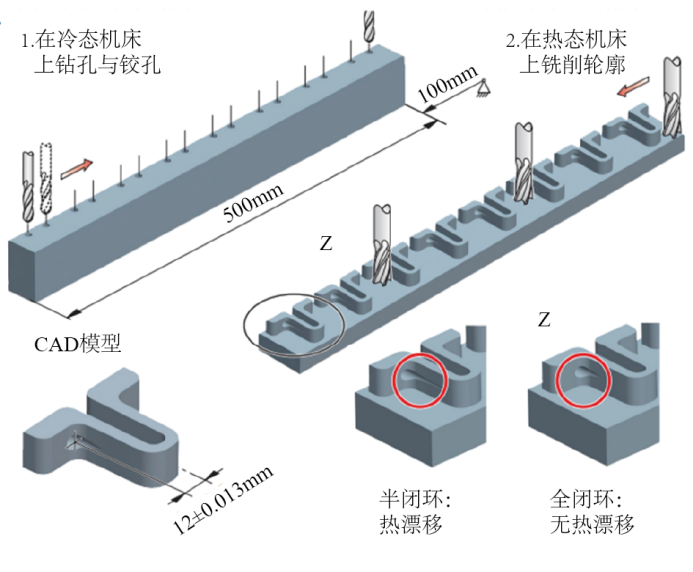

In the aerospace industry, integrated components have the advantage of ensuring optimal use of materials with minimum weight. The material removal rate of monolithic components is approximately 95% or more, and high-speed cutting (HSC) machine tools require high-speed feeds and cutting. The high material removal rate of monolithic components has exceptional economic advantages, but it also causes the ball screw to generate a large amount of friction heat. The wear and thermal expansion of the ball screw also differ during the machining process, such as the feed in case of roughing and finishing. If the feeding drive adopts a semi-closed loop control mode (without linear encoder), the size of the processed parts will be different when producing small batches and short delivery times. Due to thermal expansion, tolerance requirements may not be met. If a linear encoder is used, these errors can be avoided and the thermal expansion of the ball screw can be completely compensated in a fully closed loop.

Figure 4 The impact of driving precision on small batch part processing

In order to achieve a high surface finish of the part, sometimes very detailed structures must be machined and the processing of blow molds or die casting molds takes a long time. Many molds are now processed directly by milling, without resorting to the tedious EDM process, and the diameter of the cutter used is even only 0.12 mm. The mold milling process not only requires high precision shapes, but also requires large feeds to reduce processing time, including for high hardness materials. Typical mold processing times range from 10 minutes to several days, but dimensional accuracy cannot be sacrificed due to the rapid processing speed. The paths of the first and last cut must be exactly the same to ensure that the time saved by increasing the feed is not wasted and that repair machining is avoided. The heating of the ball screw driven by the feed axis depends on the feed speed of each axis controlled by the NC program. The length variation of the ball screw can reach 150 μm/m. These conditions make semi-closed loop control mode impossible. to ensure dimensional accuracy. The typical heat generated by a ball screw results in a 20 μm edge over a 150 mm length of the mold. Errors caused by thermal expansion of the ball screw can make defects too large to repair in about half of the molds.

To successfully complete machining commands, machine tools must have high thermal stability. Even with different loads, machining accuracy must be maintained so that required tolerance levels are maintained throughout the entire stroke, including when cutting speeds and forces vary significantly. Thermal expansion of ballscrews driven by linear feed axes seriously affects accuracy and is affected by changes in speed and magnitude of load. If the carriage position is measured only by the screw thread and the rotary encoder, the positioning error can reach 100 μm in 20 minutes. Since this method cannot compensate for these basic steering errors within the control loop, it is called a semi-closed loop control system. The operating mode of the power drive using a linear scale is a fully closed-loop control system, which measures the error of the ball screw and compensates it in the fully closed-loop control. Replacing rotary encoders with angle encoders has similar benefits because mechanical transmission components also experience thermal expansion. Linear encoders and angle encoders provide the basis for ensuring the precision of machined parts, even under the demanding and constantly changing operating conditions of machine tools.

The linear encoder that provides position feedback signals is an indispensable requirement for high positioning accuracy of machine tools. It directly collects the actual position information of the feed axis. Mechanical connection parts have no influence on the position measurement results. Motion errors, thermal distortion errors and position errors are all detected by the linear encoder and included in the control loop. Therefore, it can eliminate the following potential error sources: positioning errors caused by the thermal properties of the ball screw; reversal errors caused by deformation of the drive mechanism caused by mechanical forces; movement errors caused by ball screw pitch errors.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.