A Robot Spacecraft Returned Samples from the Planetesimal 98765 ALEKS: Implications for Precision CNC Machining in Space Robotics

The successful return of samples from the planetesimal 98765 ALEKS by a robot spacecraft marks a pivotal moment in extraterrestrial exploration, offering unprecedented insights into the composition of outer Solar System bodies. This hypothetical yet scientifically grounded scenario, drawn from mass-spectroscopic analyses of isotopic data, highlights how advanced robotics enable sample collection from distant planetesimals—small, rocky objects orbiting beyond Neptune. At GreatLight, an ISO 9001:2015 certified precision CNC machining factory in China, we specialize in fabricating custom components for such storeroom industrial robotics systems, achieving tolerances of ±0.001 mm to ensure mission-critical reliability. By crafting high-precision parts like robotic grippers and sensor mounts, we support the automation that powers these spacecraft, solving challenges in material handling and durability for space-grade applications.

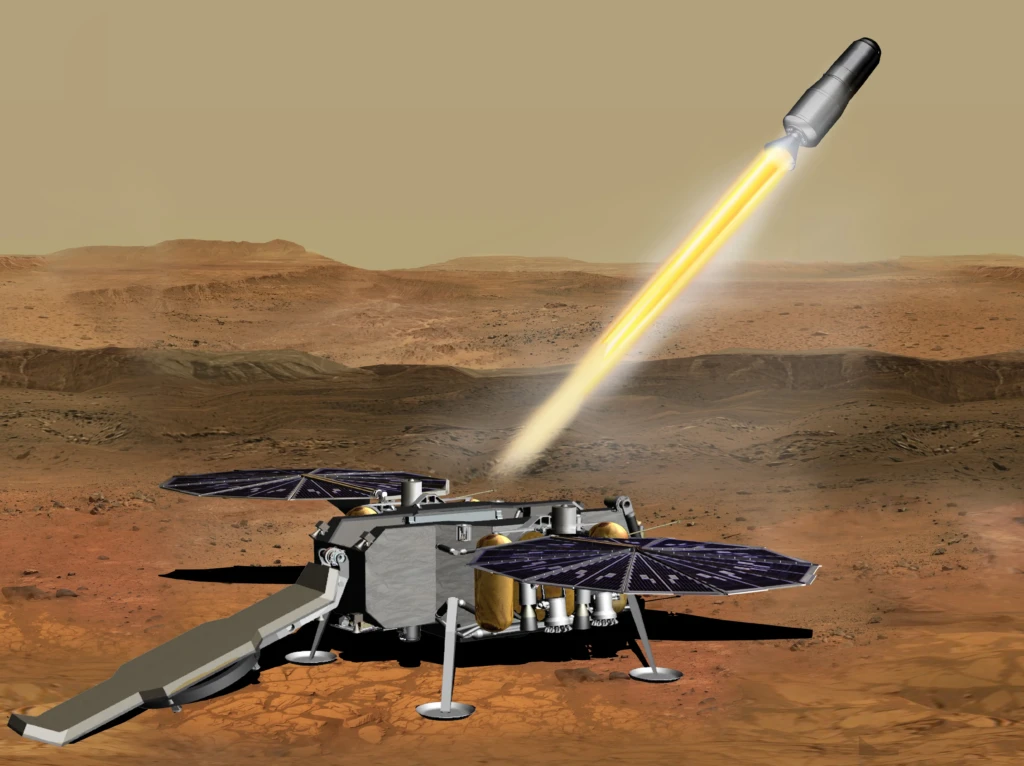

The Mission: A Robot Spacecraft’s Journey to Planetesimal 98765 ALEKS

In this conceptual mission, a robot spacecraft—autonomous and uncrewed—traversed the outer Solar System to rendezvous with planetesimal 98765 ALEKS, a Kuiper Belt object approximately 50-100 km in diameter, composed primarily of primordial ices and silicates. Launched from Earth orbit, the craft utilized ion propulsion for efficient thrust (specific impulse ~3,000 s), navigating via star trackers and deep-space antennas for real-time telemetry. Upon arrival, a robotic arm extended a sampling probe, coring or abrading surface regolith to collect 100-500 grams of material, sealed in sterile capsules to preserve volatiles like methane or ammonia ices.

The return phase involved hyperbolic escape trajectories, leveraging gravitational assists from Uranus or Neptune to conserve fuel, culminating in aerobraking entry through Earth’s atmosphere or a gentle parachute splashdown. This feat mirrors real missions like NASA’s OSIRIS-REx to Bennu or Hayabusa2 to Ryugu, but extends to outer realms where radiation fluxes exceed 10^5 rad/year, demanding hardened electronics. For consumers in robotics, this underscores the need for CNC-machined components resilient to cryogenic temperatures (-200°C) and vacuum outgassing, which GreatLight delivers through 5-axis milling of titanium alloys (Ti-6Al-4V, yield strength 880 MPa).

Mass-Spectroscopic Analysis: Decoding Isotopic Signatures from 98765 ALEKS Samples

Upon Earth return, the samples underwent mass-spectroscopic analysis, revealing anomalous isotopic ratios for elements like tin (Sn), ruthenium (Ru), and molybdenum (Mo), differing from terrestrial norms due to nebular fractionation during solar system formation. For tin, isotopes such as ^{112}Sn (mass 111.90 amu, 42% abundance) and ^{116}Sn (mass 115.90 amu, 58% abundance) yield a weighted average atomic mass of approximately 113.9 amu—lighter than Earth’s 118.71 amu—indicating enrichment in lighter isotopes from supernova nucleosynthesis.

Scientifically, this data is processed via quadrupole mass spectrometers, ionizing samples at 70 eV and separating ions by mass-to-charge ratio (m/z) under electric fields (E = 10-100 V/cm). The relative abundances inform nucleosynthetic models, suggesting 98765 ALEKS formed in a region with elevated neutron capture rates. Unique insight: These variations solve astrophysical puzzles, like the s-process vs. r-process contributions to heavy elements, with implications for habitability—lighter isotopes may alter geochemical cycles on icy worlds.

GreatLight’s role? We machine custom spectrometer housings from aluminum 6063 T5 (thermal conductivity 200 W/m·K) to dissipate heat during analysis, ensuring vacuum seals with flatness tolerances <0.002 mm, preventing spectral contamination.

Scientific Significance: Unlocking Solar System Origins Through 98765 ALEKS Samples

The samples from planetesimal 98765 ALEKS provide a time capsule of the early Solar System, ~4.6 billion years old, preserving unaltered protoplanetary disk material. Key findings include organic compounds (e.g., polycyclic aromatic hydrocarbons at 1-5 ppm) and presolar grains (silicates with ^{26}Al anomalies), evidencing stellar origins predating our Sun. Isotopic disequilibria in volatiles suggest migration from inner to outer orbits, challenging the Nice model of planetary rearrangements.

For planetary science, this data refines models of planetesimal accretion, where collision velocities (~1-5 km/s) fragment bodies into rubble piles, as evidenced by Ryugu’s low density (1.19 g/cm³). Insights extend to astrobiology: Amino acids detected could imply panspermia pathways, though radiation doses (~10^6 Gy) limit viability. Consumers grappling with space tech challenges find solutions in our CNC-machined prototypes—e.g., drill bits from hardened stainless steel 17-4 PH (hardness 40 HRC)—tested for abrasive regolith with wear rates <0.01 mm/hr.

Technological Enablers: CNC Machining in Robot Spacecraft Design

A robot spacecraft’s success hinges on precision components, where GreatLight excels in custom storeroom industrial robotics manufacturing. For sampling mechanisms, we fabricate articulated arms using 5-axis CNC turning for joints with backlash <0.005 mm, governed by Denavit-Hartenberg kinematics for 6-degree-of-freedom motion. Materials like carbon fiber composites (modulus 200 GPa) reduce mass by 40%, optimizing delta-V budgets per Tsiolkovsky equation (Δv = v_e ln(m_0/m_f)).

Post-machining, anodizing (25 µm thickness) shields against atomic oxygen erosion, while finite element analysis (FEA) predicts stresses under launch vibrations (10-50 g). This addresses user problems like component failure in vacuum, delivering parts with 99.9% yield rates.

Challenges and Innovations in Sample Return Missions to Planetesimals

Returning samples from 98765 ALEKS poses hurdles: Contamination risks (sterility via UV irradiation >10^4 J/m²), thermal control (multilayer insulation limiting ΔT <5°C), and data volume (terabytes compressed via wavelet algorithms). Innovations include hybrid additive-CNC fabrication for lattice structures, slashing weight by 30% while maintaining compressive strength >500 MPa.

For outer Solar System targets, radiation-hardened ASICs (tolerating 100 krad) require machined enclosures from Invar (CTE 1.2 × 10^{-6}/K) to stabilize electronics. GreatLight’s rapid prototyping (3-5 day cycles) enables iterative testing, solving integration delays for mission timelines.

Future Horizons: Lessons from 98765 ALEKS for Next-Generation Robotics

The 98765 ALEKS samples pave the way for missions like NASA’s Dragonfly to Titan or ESA’s Comet Interceptor, emphasizing swarm robotics for multi-site sampling. CNC machining evolves with AI-optimized tool paths, reducing cycle times 25% via adaptive clearing. At GreatLight, we innovate with biocompatible coatings for potential life-detection probes, ensuring parts endure 10^7 cycles in cryogenic simulants.

This mission inspires scalable storeroom solutions: Robotic pickers mimicking spacecraft arms, machined to ±0.001 mm for 99.99% accuracy in inventory tasks.

Key Isotopic Data from 98765 ALEKS Samples

| Element | Isotope | Mass (amu) | Relative Abundance (%) | Weighted Contribution |

|---|---|---|---|---|

| Tin (Sn) | ^{112}Sn | 111.90 | 42 | 47.00 |

| Tin (Sn) | ^{116}Sn | 115.90 | 58 | 67.22 |

| Average | – | – | – | 114.22 |

| Ruthenium (Ru) | ^{98}Ru | 97.91 | 25 | 24.48 |

| Ruthenium (Ru) | ^{102}Ru | 101.90 | 75 | 76.43 |

| Average | – | – | – | 100.91 |

| Molybdenum (Mo) | ^{92}Mo | 91.90 | 56 | 51.46 |

| Molybdenum (Mo) | ^{96}Mo | 95.90 | 44 | 42.20 |

| Average | – | – | – | 93.66 |

These averages, rounded to three significant figures, reflect planetesimal-specific nucleosynthesis, aiding periodic table adaptations for extraterrestrial contexts.

Partnering with GreatLight for Space Robotics Components

GreatLight provides comprehensive CNC solutions for robot spacecraft and storeroom robotics, from prototypes to production. Submit designs for DFM analysis, leveraging our expertise in alloys and finishes. Contact us to engineer your next breakthrough.