The Unseen Ally: Mastering Precision Drilling with Fixed-Point Commissions (And Preventing Costly Drill Wander)

Drilling operations demand surgical accuracy. Yet, achieving a consistently precise hole—perfect size, depth, location, finish—often founders on hidden obstacles. Material inconsistencies, subtle surface imperfections, and the very geometry of the drill point conspire to cause the drill bit to "wander" at the critical moment of initial engagement. This seemingly minor deviation can cascade into scrap parts, rejected batches, and costly rework. What’s the unsung hero preventing this costly drift? The fixed-point drill commission. When wielded strategically, it transforms precision drilling from a gamble into a science.

Section 1: At the Heart of Precision: Defining Drill Wander & the Fixed-Point Solution

Imagine striking a nail precisely: a clean hit drives it true. But if the hammer glances off slightly, the nail bends or veers off course. Drill wander occurs similarly on CNC machining centers. As the rotating drill touches the workpiece surface, uneven forces or an uneven surface can push the drill tip sideways before it bites deeply. The result? An oversized hole, a hole in the wrong location, potential tool breakage, or compromised surface finish—all violations of critical specifications.

The fixed-point drill commission (often called a "spot drill" or "center drill") acts as the ultimate drill pilot. Its singular mission: to create a precise, defined starting point for the main drill. By removing the variables of initial contact on the raw work surface, it anchors the drill tip, ensuring engagement begins exactly where programmed.

Section 2: Optimizing Performance: The Crucial Geometry of Angles

Simply using a fixed-point drill isn’t enough. Its geometry relative to the main drill bit dictates success or failure. The golden rule:

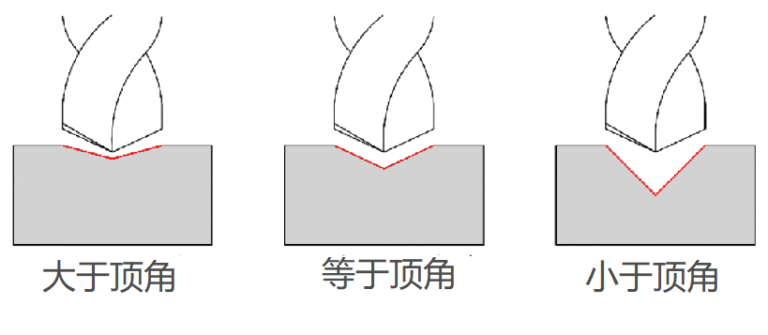

The fixed-point drill’s point angle MUST be equal to or (ideally) SLIGHTLY LARGER than the main drill’s point angle.

Why This Rule is Non-Negotiable:

Precision Guidance (Ideal Scenario – Larger Point Angle): When the spot drill angle exceeds the main drill angle, it creates a small, conical starting pocket perfectly matched to the drill’s center point. As the main drill engages, its point contacts the material first, precisely targeted within the conical recess. The outer lips of the drill only engage once the tip is secure, eliminating lateral forces that cause walking. This is the optimal setup for maximum accuracy and tool longevity.

Visual Cue: Referencing Figure 1 (Left) in the source material, the diagram clearly shows the fixed-point drill creating a conical recess wider than the main drill’s point. The main drill tip finds its path unerringly.

Acceptable Baseline (Equal Point Angle): Using a fixed-point drill with the exact same point angle as the main drill will provide significantly better starting consistency than no spotting at all. However, the outer cutting edges of the main drill will engage the material simultaneously with the center point. This offers no self-centering advantage and can subject the drill to slightly higher radial loads initially than a larger spot angle.

The Dangerous Path (Smaller Point Angle): This is a primary cause of expensive tool damage and failed precision. A fixed-point angle smaller than the main drill’s angle creates only a shallow dimple. When the main drill feeds in, its outer cutting edges strike the untouched work surface before the center point makes significant contact.

- Impact Load & Breakage: This acts like slamming a chisel sideways onto the drill tip. The sudden, uneven impact shock can instantly snap or chip the highly stressed outer corners of a carbide drill.

- Reversed Purpose & Chatter: Instead of guiding the main drill, the shallow dimple created by the spot drill hinders it. The drill point lacks initial engagement depth and can vibrate or "chatter" wildly as it tries to establish its own path, milling away the spot drill’s marks and leading to poor hole quality. This renders the preceding spotting operation worthless and potentially damaging.

Visual Cue: Figure 1 (Right/Center) illustrates this critical failure. The main drill’s periphery clashes with the unbroken surface because the small spot drill pocket doesn’t guide its tip effectively.

Section 3: Precision in Practice: Techniques Beyond Angles

- The Mark of Excellence: The core purpose of a fixed-point drill is to create a starting point. However, technicians sometimes strategically employ it for a secondary function: creating a precise chamfer. By controlling the spot drill’s depth and potentially using a drill with a specific tip geometry, they can efficiently create the conical recess needed to perfectly seat a countersunk screw head flush with the surface. This is an advanced application leveraging the tool’s inherent precision for a secondary finishing step (See Fig 2 reference).

- Surface Integrity Matters: Fixed-point commissions are most effective on relatively flat, stable surfaces. Irregular geometries pose a challenge:

- Curved Surfaces: Drilling on the side of a cylinder introduces complex radial forces. The spot drill might create a valid divot, but as the main drill engages, unintended side loads from the curvature can still push it off-axis.

- Slanted Planes: On an angle, gravity and the oblique surface feed direction conspire against alignment. A standard conical spot may not be sufficient.

- Specialized Solutions for Irregular Surfaces: For curves, slants, or other complex surfaces where standard spotting falls short, flat-bottom drills offer a compelling alternative. These tools, as the name implies, feature a ground flat face underneath the cutting lips. This allows them to mill a small flat, perpendicular landing zone on the irregular surface first, providing a stable, level staging area for the main drilling operation and mitigating eccentric forces.

Section 4: Preventing the Shift: Integrating Fixed-Point Drilling into Workflows

The cost of drill wander is measured in scrap, time, efficiency loss, and premature tool failure. Integrating fixed-point commissions systematically offers robust ROI:

- Standardize the Optimal Geometry: Implement methodology: Select spot drills with a point angle consistently 0.5° to 1° greater than the primary drill bits used. Document and enforce this rule in setup procedures. Maintain a dedicated inventory of correctly angled spotting tools.

- Validate Surfaces: Assess workpiece surfaces pre-operations. For flat surfaces, standard spotting is king. Identify cylindricity or angularity before starting; switch to flat-bottom drills where necessary.

- Rigidity & Setup: Ensure workholding is secure and minimizes vibration. Slight workpiece movement during the initial spot drill operation defeats its purpose and compromises main drill accuracy. Overhang should be minimized.

- Controller Optimization: Leverage machine control features. Program spot drill feeds and speeds conservatively to prioritize precision placement. Ensure the Z-axis retract height after spotting is sufficient to clear the spot drill’s depth before moving to the main drill cycle.

- Tool Condition Monitoring: A dull or chipped spot drill is worse than useless – it can mislead the main drill or damage the surface. Include spot drills in the regular tool inspection and replacement schedule.

Conclusion: Precision is Not Optional – It’s Engineered

Drilling may appear straightforward, but achieving high-volume precision is a complex dance of metallurgy, mechanics, and geometric physics. Drill wander is a silent saboteur of quality and profitability. By mastering the science behind the fixed-point drill commission, understanding the critical interplay of angles, recognizing its limitations, and deploying it strategically on appropriate surfaces, manufacturers can transform their drilling operations from a potential failure point into a bastion of predictable, high-quality results. In the exacting world of CNC machining, eliminating the "slip" isn’t just good practice; it’s the fundamental marker separating competent work from truly engineered perfection.