The Ultimate Guide to Taps: Mastering Thread Cutting for Optimal Performance

Understanding Tap Classification: Choosing the Right Tool for the Job

Cutting Taps

Cutting taps physically remove material to form threads through chip formation:

Straight Flute Taps

- Ideal for through-holes and blind holes

- Handle short-chipping materials like cast iron effectively

- Simple design but produces lower thread quality due to chip accumulation

Spiral Flute Taps

- Designed for blind holes (depth ≤ 3xD)

- Helical flutes evacuate chips upward

- Performance varies by helix angle:

- 10-20°: Handles threads ≤ 2xD

- 28-40°: Processes threads ≤ 3xD

- 50°: Manages threads ≤ 3.5-4xD (special conditions)

- Occasionally used for through-holes in difficult materials

- Spiral Point Taps (Gun Taps)

- Exclusively for through-holes (depth ≤ 3-3.5xD)

- Pushes chips downward with a distinctive pointed tip

- Lower cutting torque and superior thread finish

- Best solution for high-volume production lines

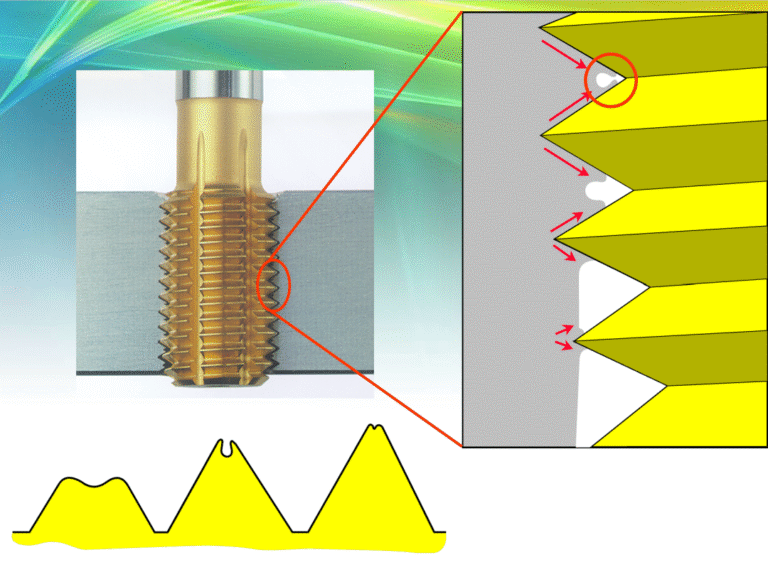

Extrusion Taps

Form threads through material deformation rather than cutting:

- Work for both through and blind holes

- Cold-forging action creates smoother, denser threads

- Key advantages:

- Higher strength due to work-hardened threads

- No chips eliminate clogging risks

- Faster cutting speeds possible

- Limited to ductile materials

- Structural variations:

- Without oil groove (blind holes)

- With oil groove (all applications – rare in small diameters)

Anatomy of a Tap: Critical Structural Parameters

1. Dimensions That Drive Performance

- Total Length: Must accommodate specific depth requirements

- Shank Configuration: Standards include DIN, ANSI, JIS, ISO

- Cutting Length: Governed by pitch – longer lengths extend tool life

- Calibration Section: Provides stability but increases resistance

2. Thread Form Essentials

- Precision Class: Matched to thread standards (e.g., ISO 1-3 ≈ H1-H3)

- Chip Flute Design: Impacts chip formation and evacuation efficiency

- Rake/Relief Angles: Affect sharpness and cutting forces

- Flute Count: More flutes improve life but reduce chip space

Material Science: The Foundation of Tap Durability

Tool Steel

Basic material for manual taps (declining usage)HSS (M2/M3)

Standard for most industrial applicationsCobalt HSS (M35/M42)

Enhanced heat resistance for tough materialsPowder Metallurgy HSS

Superior toughness and edge retention for demanding jobs- Carbide Grades

Micro-grain formulations for abrasive materials (cast iron, aluminum alloys)

Industry Insight: Leading manufacturers continuously develop proprietary alloys balancing cobalt-free formulations with premium performance.

Coating Technologies: The Surface Advantage

| Coating Type | Color | Hardness (HV) | Max Temp (°C) | Best For |

|---|---|---|---|---|

| Steam Oxide | Black | – | 300 | Carbon steels |

| Nitrided | Gray | – | 500 | Cast iron, aluminum |

| TiN (Titanium Nitride) | Gold | 2,300 | 600 | General purpose |

| TiCN (Titanium Carbonitride) | Blue-gray | 3,000 | 400 | Alloy steels |

| TiAlN (Aluminum Titanium Nitride) | Gray | 3,300 | 900 | High-speed machining |

| CrN (Chromium Nitride) | Silver | – | 700 | Non-ferrous metals |

Innovation Spotlight: Advanced coatings like LMT’s "Qi" layer combine nanocomposite structures for reduced friction and exceptional adhesion.

Mastering Tapping Parameters: The Process Ecosystem

Critical Process Variables:

- Equipment Setup: Rigid systems enable higher precision and speeds

- Tool Holding: Synchronized toolholders outperform compensated designs

- Coolant Strategy: Lubrication > Cooling (emulsion >10% concentration)

- Cutting Parameters (Feed/Speed):

- Start with manufacturer recommendations

- Reduce speeds when facing:

- Workpiece hardness variations

- Extended tool lengths

- Horizontal machining orientation

- Manual operations (drill presses)

Precision Engineering: Navigating Tolerance Systems

ISO Tolerance Standards vs. Japanese Systems

- OSG Cutting Taps (OH system): Starts at low limit in 0.02mm increments

- OSG Extrusion Taps (RH system): Starts at low limit in 0.0127mm steps

| ISO Class | Tolerance Band (mm) | Typical Application |

|---|---|---|

| 4H | 0.100 | Aerospace fasteners |

| 5H | 0.125 | Automotive components |

| 6H | 0.150 | General engineering (most common) |

| 7H | 0.175 | High-temperature alloys |

Expert Tip: For gray cast iron, select class 6G taps to account for bore expansion from tool wear.

The Six Commandments of Tap Selection

- Thread Standard: Metric, UN, Whitworth, etc.

- Hole Configuration: Through-hole vs. blind hole

- Workpiece Material: Steel, aluminum, superalloys?

- Depth Requirements: Hole depth vs. full thread depth

- Precision Class: Tolerance requirements

- Tool Specifications: Length, shank type, coating

Optimizing for Challenging Applications

Interference Scenarios:

- Reduce Vc (cutting speed) by 40% and Fz (feed) by 30% in unstable setups

- Use spiral point taps where chip evacuation is critical

- Remember that extrusion taps demand perfected hole size (±0.05mm)

Case Study: High-silicon aluminum components saw productivity increase 220% after switching from TiN-coated straight flute taps to CrN-coated spiral flute designs with optimized helix angles.

Conclusion: Precision as Philosophy

Mastering the science of taps transforms threading from a necessary operation to a strategic advantage. The 0.01mm tolerance decisions, the 5° helix angle adjustments, and the molecular-level coating selections collectively determine whether a production line meets quotas or faces downtime. The most successful manufacturers don’t just use taps – they engineer threaded connections with the precision of watchmakers, leveraging every advancement in metallurgy, coating technology, and geometry optimization to achieve flawless, efficient thread production.

(Note: Technical specifications are based on industry standards; always verify with your tooling supplier for application-specific recommendations.)