Precision CNC machining of copper tube assembly: unlocking performance and aesthetics

Brass is a timeless alloy, mainly copper and zinc, that has attracted industry for centuries. The unique combination of its characteristics – high quality processability, inherent corrosion, attractive aesthetics, excellent conductivity and good strength-to-weight ratio – makes it an indispensable material in countless applications. When these components require high precision, complex features and consistent quality, Accurate CNC machining Appeared as an undisputed advocate of manufacturing. This blog delves into the world of CNC machining brass, exploring its advantages, applications and why working with experts like Great Improve the entire process.

Why Brass and CNC machining is a perfect match

Certain brass grades, such as the C360 free-play brass, exhibit unparalleled processability compared to steel and even some aluminum alloys. This translates directly into manufacturing efficiency and excellent surface surfaces:

- Reduce tool wear: Compared to harder metals, copper tube machines are easy to minimize cutting forces and significantly extend tool life. This reduces operating costs and reduces downtime for tool replacement.

- High precision and complex geometric shapes: CNC machining (especially multi-axis machining) provides excellent dimensional accuracy (usually maintaining tolerances at +/- 0.01mm or more tightly), and has the ability to create complex internal features, thin walls, complex contours, and other methods that are difficult or impossible. Consider valve bodies, precise accessories, complex electrical connectors or decorative building elements.

- Excellent surface: Brass produces a naturally smooth surface under processing. This can often eliminate or minimize secondary finishing operations, providing a cost-effective way to both precise and aesthetically pleasing parts.

- Chip control happiness: The brass cleanly breaks down into small, easy-to-manage chips while some other metals produce miscellaneous chips, troublesome chips. This can improve process reliability, machine safety, and simplify chip processing.

- Material versatility: CNC machining can effectively process various brass alloys (C360, C385, C464 Navy Brass, C260 Ink Cartridge Copper Tube, etc.), and can choose based on specific strength, corrosion resistance (especially in the marine environment), conductivity or trans resistance requirements based on specific strength, corrosion resistance (especially in the marine environment).

Precision-machined brass shine (application)

The accuracy and versatility of CNC-machined brass means it is found in key components of different departments:

- Pipeline and fluid treatment: Precision valve body, accessories, compression nuts, faucet cartridges, pump components. The corrosion resistance of copper tubes and the processability of sealed surfaces are crucial.

- Electrical and Electronics: Connector pins, terminals, switchgear components, relays, RFI shielded parts. Take advantage of the excellent conductivity of brass and the ease of use that makes it easy to form complex shapes.

- car: Fuel system components (especially old or professional vehicles), sensor housing, bushings, decorative trim parts, professional fasteners.

- Marine Corps: Highly corrosive naval brass accessories, propeller shaft (specific alloy), instrument case, deck hardware.

- Musical instrument: Precision valves, slides, cigarette holders, accessories. Relying heavily on acoustic properties and smooth surfaces achieved by CNC machining.

- Industrial Machinery: Gears, bearings, bushings, wear plates, custom machine components requiring low friction, corrosion resistance and dimensional stability.

- Decoration and architecture: Complex door handles, patches, bonus components, luxury installations. The precise details of the CNC enhance the aesthetic appeal of brass.

Great Advantages: Five-axis CNC machining expertise

Although brass is machine-friendly in nature, maximizing its potential and effectively realizing truly complex geometries can effectively demand advanced capabilities. This is Great Distinguish yourself from your primary manufacturing partners:

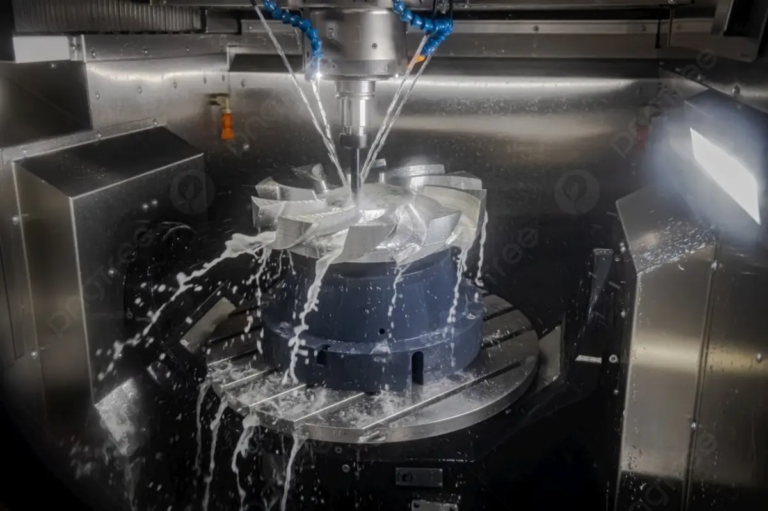

- State-of-the-art five-axis CNC machining: Our arsenal of advanced five-axis CNC machining centers is the game rules for changing complex brass components. Unlike traditional three-axis machines, the five-axis technology can move along five axes at the same time. This can:

- Single setting processing: Complex parts can usually be done in one setup, greatly reducing handling errors, fixed costs and total lead time.

- Geometric freedom: Ability to machine complex undercuts, composite angles, deep cavity and organic shapes with fewer shafts.

- Best tool access and direction: The spindle can oriented the tool to the workpiece from almost any angle, allowing shorter tools to increase stiffness and improve surface finishes in challenging functions.

- Unparalleled precision: Improved accuracy and repeatability for the most demanding brass applications on all five axes.

- Material mastery and quick customization: We have deep expertise in processing a wide range of brass alloys. We understand their specific behavior, the best speed and feeds, and how to get the best results for your unique requirements. Need a quick turnaround? Our effective workflow and advanced equipment ensure that your custom brass parts are delivered quickly without compromising quality.

- Comprehensive post-processing and completion: Gregtime is more than just processing. We provide a Full set of post-processing services Delivery turnkey components:

- Precision burrs: Make sure every edge is smooth and safe.

- Polishing and polishing: From satin to mirror-like brilliance, achieve an unparalleled cosmetic finish.

- Electroplating (nickel, chromium, gold, silver, tin, etc.): Enhance corrosion resistance, wear characteristics, welding properties, conductivity or appearance.

- Shooting/bead explosion: Creates a uniform matte or textured surface.

- Paint/coating: Prevent destruction of decorative parts.

- Problem Solving and Design Support: Facing the challenging brass section? Our experienced engineers work together to improve design of manufacturability (DFM), optimize costs, and ensure the success of projects from prototype to mass production.

- Cost-effective excellence: By leveraging our five-axis efficiency, material knowledge and internal finishing capabilities, Greatlight offers extraordinary value to deliver high-precision brass components at a highly competitive price.

Conclusion: Improve brass components with precision and expertise

Precise CNC machining unlocks the full potential of brass, transforming it from a multifunctional alloy into high-performance, aesthetically pleasing and size-critical ingredients. Invest in advanced features like five-axis machining when your project needs more than just basic machining (when they require complex geometry, micron-scale accuracy, reliable finishes, or fast turnaround).

Gregmight embodies this commitment to excellence. With our industry-leading five-axis CNC technology, deep material expertise, comprehensive internal finishing options and dedicated problem-solving methods, we will be uniquely a trusted partner for all custom precision brass components. We not only meet the specifications; we exceed expectations.

Ready to experience the Greatlime difference?

Customize precision brass parts now at the best price and quality! Contact our engineering team today for consultation and quotes. Let’s turn your design into reality.

FAQ: Precision CNC machining of brass

Q: What is the most common brass alloy processed by CNC?

A: The C360 (free play brass) is by far the most popular due to its excellent processability. Others include C385 (building bronze) for marine environments, C464 (naval brass), C260 (Cartridge Brass) for good shape, and C353/C485 for specific regulations (e.g. C353/C485).

Q: Can CNC-machined brass parts meet strict tolerances?

Answer: Absolute. Using advanced CNC equipment such as five-axis machines and optimized processes, parts can reliably maintain tolerances +/- 0.01mm (0.0004") Key features that are even closer depending on the size and geometry of the part.

Q: Does brass need lubrication during CNC processing?

A: Yes, cooling and lubrication are crucial. Brass machine is relatively "Cool," Cutting liquid:

- Prevent the tool from building advantages.

- Improve surface finish.

- Easily evacuate the chip.

- Extend tool life. Typically, soluble oil or semi-synthetic liquid is used.

Q: Can CNC machining create threading functions in brass?

A: Yes, CNC machining is excellent in creating highly accurate thread characteristics – interior (knocking holes) and exterior (screws, studs). The processability of brass makes it ideal for producing clean, firm lines.

Q: What surface finishes can be performed after CNC machining brass?

A: The brass arranged has good results. Greatlight provides a sharp expansion option for post-processing:

- Mechanical: Polish (mirror), polish (high gloss), tumbling (smooth), bead blasting/shooting (matte/satin).

- plating: Nickel, chromium, tin (soldering), silver, gold (decorative/conductive).

- coating: Transparent paint (anti-tarnish), paint (professional color).

- pat: Chemical treatment of antique finishes.

Q: Is brass suitable for high temperature applications?

Answer: Brass has moderate temperature resistance. While better than some plastics or lower temperature metals, continuous high temperatures (above 200°C/392°F) may cause annealing (softening) or creep. Specific high-strength brass alloys are better, but alternatives such as bronze or nickel alloys are usually extremely high in heat.

Q: Is brass magnetic?

Answer: The most common form (mainly C360, C260 and other copper-zinc alloys), brass is Non-magnetic. Certain dedicated alloys containing elements such as iron (e.g., some lead-free adjustable brass) possible Shows slight magnetic properties. However, standard brass is absolutely non-magnetic, which is important in EMI/RFI shielding.

Q: How does five-axis machining particularly benefit from brass parts?

Answer: Allowed:

- Machining complex contours and undercuts in a single setup.

- Use shorter, more robust tools to improve accuracy and complete depth functions.

- The composite angle is precisely achieved without error-prone fixtures that change.

- The overall output is faster due to reduced settings.

- High consistency and accuracy of all geometries.

Q: Why choose Greatlight for my brass CNC machining needs?

A: Greglight combines Advanced five-axis CNC function and Deep brass material expertise,,,,, Comprehensive internal post-processing,,,,, Dedicated engineering support,,,,, Rapid prototyping and production turnoverand the commitment to provide Excellent value and quality Precision brass assembly for customization. We are a truly one-stop solution for complex, high-precision parts.