In today’s fast-paced manufacturing landscape, accuracy is key to producing high-quality parts that meet various industry standards. In the manufacturing technology array, CNC (Computer Numerical Control) precision parts manufacturing stands out because of its ability to precisely size and finish complex parts. This approach is essential in the production of parts in the aerospace, automotive, medical and consumer electronics industries. The cutting-edge of this technology is five-axis CNC machining, which provides unparalleled versatility and precision.

Introduction to CNC precision parts manufacturing

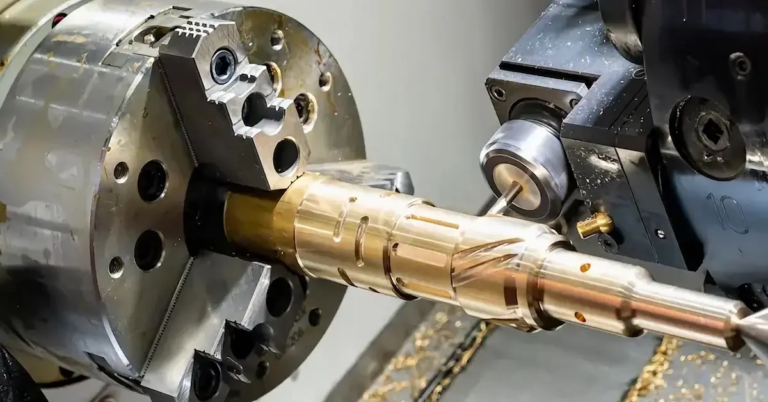

CNC Precision Parts Manufacturing uses computer-aided design (CAD) software and CNC machines to manufacture parts with high precision. This process starts with the design of the parts using CAD software and then converting it into numerical codes that the CNC computer can understand. The CNC machine reads this code and executes instructions to cut the material into the desired form. The accuracy and repeatability of CNC machining make it ideal for manufacturing complex parts that require tight tolerances.

The role of five-axis CNC machining

Five-axis CNC machining is a complex form of CNC machining that allows cutting tools to move at the same time on five different axes. This capability can be used to make complex shapes and design machining through traditional three-axis or four-axis machining. The additional shaft allows machining of parts with complex geometries, such as those found in aerospace and medical components, with a high degree of accuracy and efficiency.

Benefits of CNC precision parts manufacturing

- Accuracy and accuracy: CNC machining is able to produce parts with very tight tolerances to ensure the final product meets the required specifications.

- Efficiency and speed: After setting up the program, the CNC machine can run continuously with minimal supervision, so as to produce parts quickly and efficiently.

- Consistency and reliability: CNC machining ensures that every part of the production is consistent and reliable, reducing the potential for variability and human error.

- flexibility: It is simple to have the ability to easily adjust CAD design and reprogram CNC machines, change the design or switch between different parts.

Materials and customization

CNC precision parts manufacturing can be used with a wide range of materials, including metals, plastics and composites. This versatility, combined with the ability to customize parts to specific requirements, makes CNC machining the first choice solution for industries requiring unique and precise components. From aluminum and steel to titanium and plastics, the choice of materials depends on the application and characteristics required for the final product.

Post-processing and completion of services

In addition to processing, many manufacturers also offer one-stop post-processing and finishing services. These services can include anodization, electroplating, painting and assembly, etc. to ensure that the final product meets all necessary aesthetic and functional requirements. This comprehensive approach simplifies the production process, saves time and reduces the need to outsource other services.

in conclusion

CNC Precision parts manufacturing, especially five-axis CNC machining, represents the pinnacle of modern manufacturing technology. Its ability to have high precision, efficiency and flexibility makes it crucial for industries that require complex and custom components. With the continued advancement of CNC technology and the integration of artificial intelligence and automation, the future of precision parts manufacturing looks promising. Whether used for prototypes, small batches or mass production, CNC machining is ready to continue to play a key role in shaping the world of manufacturing.

FAQ

-

What materials can be used in the manufacturing of CNC precision parts?

- A variety of materials can be used, including metals (aluminum, steel, titanium), plastics and composites, depending on the application and desired characteristics.

-

What is the difference between three-axis, four-axis and five-axis CNC machining?

- The main difference is the number of axes the cutting tool can move with it. Five-axis machining provides the most functionality to produce complex shapes and designs.

-

Can CNC machining produce parts using complex geometry?

- Yes, especially with five-axis CNC machining, it can handle complex shapes and designs that are challenging or unproductive for lower shaft machines.

-

Is CNC Precision Parts Manufacturing suitable for small batch production or prototypes?

- Yes, CNC machining is highly adaptable and can be used in small batches or one-time prototypes due to its flexibility and ease of adjusting design and procedures.

- How to ensure accuracy and accuracy in CNC machining?

- The use of CAD software and precise CNC computers ensures that the parts are made into precise specifications and have very tight tolerances, ensuring high accuracy and accuracy.