The Rise of Robot Exchange: How Three Simple Steps Can Revolutionize Factory Automation

In a world where technology is constantly evolving, automation has become an essential component of modern manufacturing. Gone are the days of manual labor and tedious processes, replaced by the precision and efficiency of machines. Among these machines, robots have emerged as a game-changer, transforming the way we produce, manage, and maintain our industries. In this blog post, we’ll explore the rise of the Foxconn Robot Exchange, a pioneer in factory automation, and how it’s simplifying the process with just three steps: Integration, Automation, and Optimization.

Step 1: Integration

The first step in the Foxconn Robot Exchange is integration, where factory owners and management come together to understand the needs of their production processes. This involves identifying areas that are most critical to production, as well as noting any inefficiencies and bottlenecks. By analyzing these factors, they can create a tailored solution that meets their unique needs. This step is crucial in ensuring that the robot exchange is effective in streamlining processes, reducing costs, and increasing productivity.

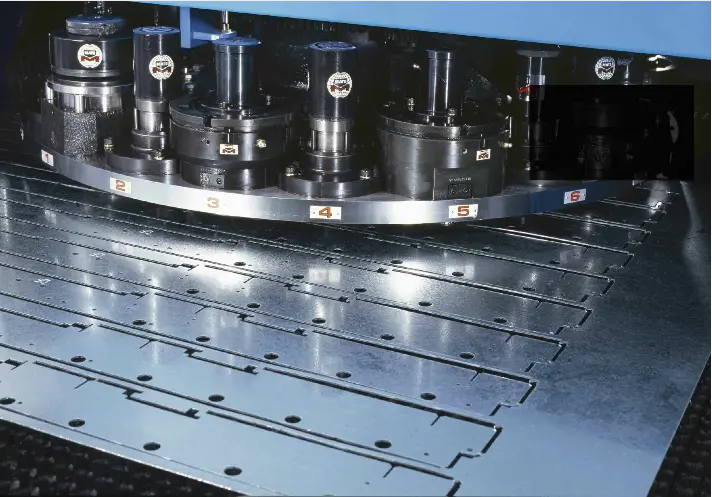

Step 2: Automation

With the integration complete, the next step is to automate the selected processes. This is where the Foxconn Robot Exchange shines, with its advanced AI-powered robots designed to mimic human movements with precision and speed. By automating tasks such as assembly, inspection, and packaging, these robots can reduce defects, increase output, and minimize the need for human intervention. What’s more, they can work 24/7, without breaks, and with minimal maintenance, making them an attractive option for industries that require high-volume production.

Step 3: Optimization

The final step is optimization, where the robot exchange is fine-tuned to ensure maximum efficiency. This involves monitoring the performance of the robots, gathering data, and making adjustments as needed. By continuously optimizing the system, factory owners can maintain the highest level of quality, while minimizing costs and improving product output. This step is critical in ensuring that the robot exchange remains effective in the long term, as new challenges and opportunities arise.

The Benefits

So, what does this mean for industries? The Foxconn Robot Exchange is opening up a world of possibilities. With three simple steps, factories can:

- Increase productivity by up to 30%

- Reduce labor costs by up to 50%

- Improve product quality by up to 20%

- Reduce energy consumption by up to 15%

Conclusion

The Foxconn Robot Exchange is more than just a technology – it’s a game-changer for industries. By integrating, automating, and optimizing their processes, factory owners can revolutionize their production capabilities, transform their businesses, and stay ahead of the competition. As we move forward, it’s likely that we’ll see even more advancements in robot exchange technology, further streamlining the manufacturing process and driving growth. One thing is certain – the future of factory automation has never been brighter.