Resin3DPrinting is a powerful tool3D printingtechnology, which uses light and plastic raw materials to create objects. These beams can precisely cure UV-sensitive resins in layers, creating detailed three-dimensional models. Although the resin3DPrinters can produce stunning high-definition effects, but this3D printingTechnology is not without its challenges.

Every resin print requires a support structure. The support structure is a cylindrical structure with angled ends and a pointed tip that supports the print and helps it resist pressure. They are essential to prevent models from detaching from the print bed or small details being torn off. Even though the media are designed to be removable and leave as little trace as possible, getting them right is no easy task. Knowing how to add, modify and remove supports is essential to ensure successful resin printing.

In this article,magic monkey networkLiquid crystal resin will be introduced3DResins associated with printingsupportof all knowledge, because it is the most common among amateurs.in additionMany of our tips also apply to whole resins3DPrint. To learn how to adjust print orientation, adjust media thickness, remove supports, and much more, keep reading!

ResinThe basics of 3D printing

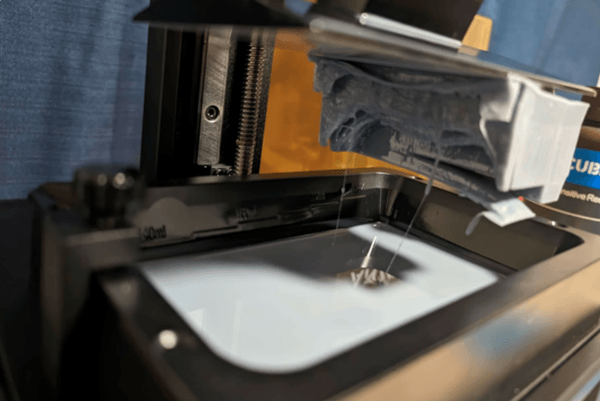

Mastering resin printing is not an easy task (Source:FeverFocus, via Reddit)

Resin3D printingThis may seem complicated at first, but it can be broken down into a few main parts: the build tray, the resin tank,FEP and light source.

Table construction vs traditionalAn FDM printer is basically the same, it’s where the object is built layer by layer. The aptly named resin tank is a resin holding tray with an FEP bottom. FEP, or Fluorinated Ethylene Propylene, is a transparent sheet specially formulated to let UV rays pass through.

ForLCD resin printing, the light source is an LED located under the LCD screen. It irradiates UV light in precise increments to precisely cure the resin layer. The screen acts as a mask, showing only the pixels required for the current layer, while other pixels are hidden. The details are determined by the number of pixels, the more pixels the higher the resolution.

These basic components work together to create a resin print. The build plate is lowered into the resin tank and, depending on the height of the layer, approximately50 micron gap. Once adjusted to the correct height, the ultraviolet light from the LCD panel flashes, solidifying a thin layer of resin. Once the layers have hardened, the build plate is lifted to allow the new resin to flow underneath, and the process is repeated. Each layer builds on the next, with the bottom layer serving as an anchor for the print. Once printing is complete, the machine simply lifts the print bed and lets the excess resin drip off.

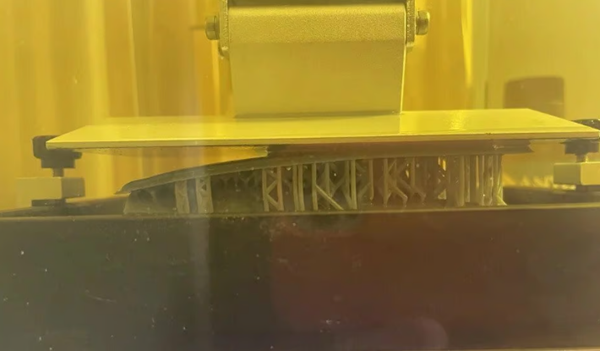

Advantages of bracing

The supports are almost all made of resinimpressionAn important aspect of using media correctly is to ensureimpressionOne of the best ways to achieve quality. Supports are important for several reasons. In resin printing, supports are usually anchor points that hold layers to the build plate, rather than something likeThe layers are attached to the build plate like FDM printing. As a layer solidifies, the build plate lifts and that layer must move away from the FEP to make room for the next layer. Without proper support structures to attach the various parts of the object to the build platform, the freshly cured layers can stick to the bottom of the container and crack.

Remember that the thickness of each layer isBetween 10 and 50 microns, it is not difficult to damage a layer thinner than a hair. If you end up with print failures, layer breakage, and loss of the final printed part due to lack of support, some Reddit users recommend filtering the resin. Paint filters do a great job filtering out particles that might otherwise create imperfections on your prints or build up and affect future layers of prints.

Another reason why supports are so important is that,Unlike FDM printers, resin printers can only print very small overhangs. If the overhang is significant, there will be significant subsidence or complete collapse. Improper placement or insufficient support can cause minor issues, such as dents, as well as major issues, such asimpressiondelamination orFEP perforation).

for biggerimpressionlack of support can lead to warping or even delamination. Delamination is usually caused by incorrect cure settings, but whenDelamination can also occur when the force between the FEP and the build plate is strong enough to separate the layers. This will immediately destroyimpressionand let the remaining layer solidify inon the FEP, creating a mess that is difficult to clean up. To improve your support systems and resin printing, or simply learn something new, read on for some great tips and tricks.

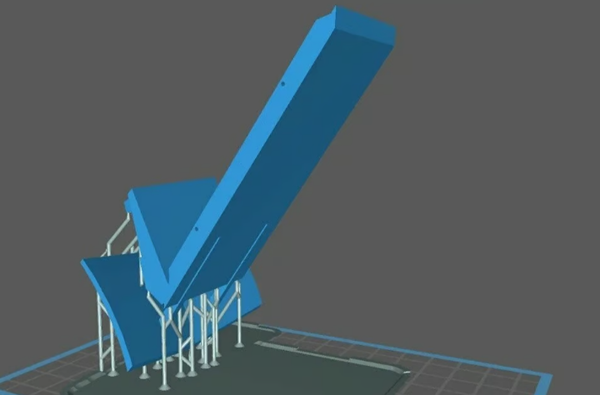

1、Print direction

Different models may require different orientations (source:SmokeAndGnomes, via Reddit)

One of the most basic, but often overlooked, tips for getting better support is to rotate your print in the slicer. Ideally, you should orient your print so that it requires less support,3D printingThe time required is shorter.

As mentioned previously, each layer of a resin print is continuous and builds on the layer below it. In most cases, you will need to rotate the flat bottom model so that it is slightly tilted. The inclination can be reduced withFEP panel contact area, thereby reducing peeling force. If the first flat layer separates from the bottom of the container, the model may warp or tear (even with proper support).

For best results, prints can be rotated30-45% to reduce the impact of the bottom surface. Almost all resin slicers have the ability to rotate objects. For example, in ChiTuBox, the rotate tool is on the left with a large font below it. Simply select the tool and a panel will appear with angle measurements, and a three-axis wheel will appear in the middle of the workbench.

This simple rotation produces better prints, using fewer supports and fewer imperfections. The only thing to note is if the flat edge is parallel to the build plate when rotating. Just like a tent, it will collapse into an unsupported position. The same goes for the resin layer. Unless the support density is extremely high, every gap between the supports will sag because no support force is present.

2、Determine strength and thickness

These supports are too weak to support the model (source:Menneképis via Reddit)

The support is responsible for attaching the print to the surface of the bed. It should be strong and thick, but not too big to avoid leaving unnecessary marks. In most slicers, the media thickness comes in three sizes: small, medium and large. Support tips can vary even more, with common sizes ranging fromIt varies from 0.2 mm to 0.5 mm. Different sizes result in different levels of stress throughout the printing process.

In large prints,The suction power of FEP is much greater, so the diameter of the holder tip must be thicker. For these models, it is better to use high support density and interconnected beams. Connecting neighboring beams creates a rigid structure to compensate for areas of higher stress. The downside is that it leaves a lot of support marks and requires a long post-processing period.

An alternative to high support density is to use a few large supports at the bottom as anchors and small to medium supports elsewhere to reduce streaking and resin usage. for heavierimpressionit is better to use a larger support head. The weakest point of the support structure is the narrow tip where it contacts the object. As a result, prints sometimes come loose from the undersized media head.Thicker media nozzles such as 0.4mm or 0.5mm can help solve this problem.

For smaller prints with lots of fine detail, a small support should provide all the strength needed. Furthermore, theseimpressionThe diameter of the support head should be smaller to preserve fine details. The main concern is to avoid damaging dents and marks caused by removing the supports. In most microtomes, the resin tip can be changed to a spherical shape in the options menu. The spherical vacuum head does not easily leave marks when removed, and even if it leaves marks, it is only a small dent. These small bumps are easier to remove by post-processing than those left by traditional cone tips.

Determining the ideal media for printing can be tricky. a personReddit users attribute it to “big print, big support.” Since everyone’s machine and resin combination is different, there is no simple ratio for determining media strength. Probably the best way to learn is through trial and error. Remember, it’s better to have too much support than not enough.

3、Generate media

when automaticallysupportWhen it fails (Source:PhantomShot811 via Reddit)

In recent years, automated support structures have become a powerful tool for resin printing, but they are not perfect. If your slicer’s auto-support feature isn’t quite what you expected, don’t worry. In almost all resin slicers, manual supports complement automatic supports. They can fix problems your computer is missing, as long as you know what to look for.

Manually adding media takes some time, but when combined with automatic media generation, you can achieve high-quality results. The method of manually adding supports varies between slicers, but generally involves clicking or dragging over a selected area. When looking for areas that need support, remember to anchor the piece and not just support it. Look for flat or long overhangs and large areas. For example, a large overhang parallel to the build plate will require more intensive bracing to counteract sag if it cannot be oriented. It’s also a good idea to add supports to areas where you’ve had problems with previous prints.

Islands are often the most important factor affecting media placement, and their absence can lead to serious print failures. An island is a part of an object that has no surface to build on, whether it’s a support structure or other parts of the model. This way the island is printed in the air (or rather in the resin tank). To identify islands, use the layer slider in most slicers and look for places with large overhangs or places where objects appear to be floating in mid-air. If the auto-strengthen feature misses one of these locations, simply reinforce the area manually.

When using the slicer’s auto-gen support feature, remember that while this eliminates tedious work, a final check is still required.

4、add a raft

The raft did not have good grip on the bed, which resulted inimpressiondestroyed (source:ra3ndy, via Reddit)

Another simple but very effective tip to protect your print and avoid media failure is to use a raft. A raft is a thick layer of resin on the build plate that can cure for additional time to form a strong bond between the resin and the build plate.

Without solid support, prints tend to come loose from the plate due to movement, pressure and other forces. Although cure times vary by brand and ingredients, a cure time generally equal to eight times the plate cure time is generally preferred. Excessive curing will cause the plate to adhere more strongly, providing a better supporting base.

Typically, raft designs are enlarged to provide a larger base, as this provides a greater surface area on the build plate, thereby increasing grip. Enlarging the raft to increase adhesion can be particularly useful when working with particularly tall or dense prints. Tall or heavy objects will put more pressure on the raft.

Although the emphasis on raft adhesion may seem excessive, the role of the raft is to support and resist the weight of the entire print.The vacuum force of each layer on the FEP. The stress placed on the printing plate caused by the process of pulling away from the FEP is several times greater than the number of layers on the printing plate, often reaching thousands. Once the raft loses traction, objects fall into the resin tank, creating a thick layer of hardened resin on the FEP.

With these adhesive forces, it may be difficult to remove the plate after a successful print. To facilitate successful removal of the raft from the plate, the edges are beveled by default to allow the scraper to gain leverage. The edge angle may be increased or decreased, which will affect the ease of final removal. The printing plate is the foundation of any good photo, and the time spent adjusting it is well worth it.

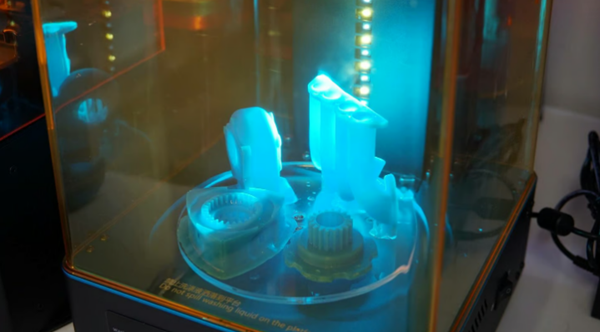

5、Removing supports and post-processing

Be sure to remove the supports before post-curing to avoid damaging the model (Source:All 3DP)

Once each support has been carefully placed and every angle checked, your print is ready to go. But now, how best to remove these pretty supports?

Removing supports can seriously damage your print if not done correctly. To avoid chips and cracks, you should always remove supports before curing the model. When you first remove the print, the print is still soft and slightly malleable. This makes it easy to remove individual supports without having to worry about thin sections cracking or pieces of print falling off.

For models with a lot of support, heating can make the removal process easier.For example,“Immerse the model in hot water for approximately 30 seconds. The heat will soften the supports, making them easier to remove and reducing damage to the model.

For media that is only in specific areas, a heat gun can work just as well. For rigid or larger supports, it is advisable to use wire cutters to cut the support close to the model. Any remaining raised areas can be scraped off with a sharp knife for best results. Avoid removing brackets by hand as this can cause gouges and small imperfections.

Once all supports are removed, the item can be cured in a UV curing station or under strong direct sunlight. Post-curing hardens the print and removes any residual adhesion. Once cured, the print is hard enough to be sanded to remove any remaining support elements. Use firstSand with 220 or 400 grit sandpaper, then work your way slowly. Always wear a protective mask when sanding.

By priming, coloring and sealing you can take your prints to the next level. Then your resinFinished productIt’s ready to use or display!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.