Understanding 5-Axis Machining

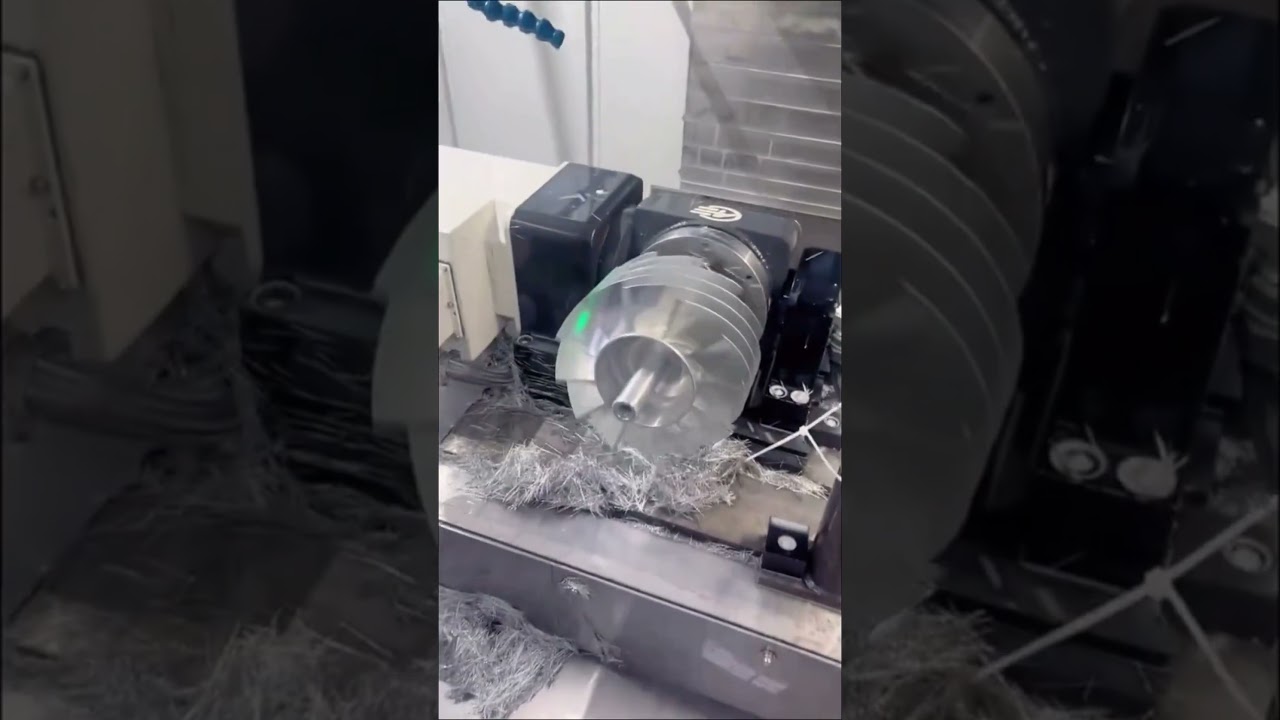

In the world of precision manufacturing, the ability to create complex geometries with high accuracy is paramount. One of the most advanced techniques available for achieving this is 5-axis machining. This sophisticated CNC (Computer Numerical Control) process allows for the cutting tool to move along five different axes simultaneously, facilitating the creation of intricate components like impellers.

What is 5-Axis Machining?

5-axis machining refers to the capability of a CNC machine to move a tool or part in five different directions simultaneously. This technique enhances flexibility and complexity in manufacturing compared to 3-axis systems that only move along the X, Y, and Z axes. The two additional axes in a 5-axis machine are typically rotational, allowing the tool to approach the workpiece from any angle.

This form of machining can further be categorized into two types:

- Table-Table Machines: The workpiece remains stationary while the spindle moves.

- Head-Head Machines: The spindle is fixed, while the workpiece is moved.

With the additional degrees of freedom, 5-axis machining is particularly useful for creating components with elaborate shapes and contours, making it ideal for parts like impellers.

The Significance of Impellers in Various Industries

Impellers are critical components in many mechanical systems, including pumps and turbines. They are used to transfer energy between a rotor and a fluid. The design of an impeller affects the efficiency, performance, and reliability of the system it is integrated into, which is why precision in manufacturing these components is crucial.

Industries such as aerospace, automotive, marine, and energy rely heavily on high-performance impellers. Given their complex shapes and the need for precision, they often rely on advanced manufacturing techniques like 5-axis machining.

Advantages of 5-Axis Machining for Impeller Manufacturing

-

Enhanced Complexity and Precision:

5-axis machining can produce highly complex geometries that are typically unattainable through other methods. This capability is particularly vital for impellers, which often feature unique blade designs, varying diameters, and complex curves. The improved precision means that the functionality of the impeller is not compromised, leading to better performance in its end-use application. -

Reduced Setup Time:

The ability to machine multiple faces of a part in a single setup is a game-changer. In traditional 3-axis machining, multiple setups might be required to achieve the desired shape. This can lead to increased machining time and potential for errors during re-fixturing. In contrast, 5-axis machining permits complete machining of complex parts in one go, thus optimizing productivity. -

Improved Surface Finish:

Due to the nature of its cutting dynamics and the ability to approach the workpiece from various angles, 5-axis machining often results in superior surface finishes. This is highly beneficial for impellers, as smoother surfaces can lead to enhanced fluid dynamics and improved energy efficiency in applications. -

Material Efficiency:

5-axis machines can access more of the workpiece, allowing for intricate shapes to be machined with less waste material. This is particularly important in machining high-cost materials used in aerospace components where material conservation translates directly into significant cost savings. - Higher Tool Life:

By allowing for better tool engagement angles and optimizing cutting paths, 5-axis machining can extend the life of cutting tools. Reduced wear and tear lead to fewer tool changes, decreasing downtime and enhancing overall operational efficiency.

Considerations for 5-Axis Machining of Impellers

Despite the numerous advantages, 5-axis machining does present its own set of challenges. Manufacturers must be aware of several factors to maximize the benefits of this advanced machining technique.

1. Machine Setup and Calibration:

Precise calibration of the CNC machine is crucial to ensure that the impeller is machined accurately. Any misalignment can result in costly errors and compromised performance of the final product.

2. Programming Complexity:

Programming a 5-axis CNC machine requires a deep understanding of both the CAD (Computer Aided Design) model and CAM (Computer Aided Manufacturing) software. Manufacturers must invest in software and training to ensure that their machinists are adept at programming complex geometries.

3. Tool Selection:

Choosing the right tool is essential for effective 5-axis machining. Different materials, geometries, and machining strategies may require specialized tools and techniques. Thus, a comprehensive tool inventory and a well-planned management strategy are necessary.

4. Cost Implications:

While 5-axis machining can be more cost-effective in the long-run due to reduced labor and material costs, the initial setup and acquisition of technology can be expensive. Companies must balance these costs against the potential long-term gains.

Success Stories: Industries Utilizing 5-Axis Machining for Impeller Production

Many industries have embraced the benefits of 5-axis machining to produce high-quality impellers. Here are some examples:

Aerospace Industry

In the aerospace sector, precision and efficiency are non-negotiable. Companies manufacturing turbine engines require impellers that can withstand extreme pressure and temperature. Utilizing 5-axis machining has enabled these manufacturers to create impellers with optimized aerodynamic profiles, enhancing performance while minimizing weight.

Marine Applications

The marine industry relies on efficient watercraft propulsion, which depends on the performance of impellers. 5-axis machining allows manufacturers to produce lightweight, high-strength impellers that improve fuel efficiency and speed without compromising reliability in harsh marine environments.

Energy Sector

In energy production, specifically in wind turbine manufacturing, the blades and associated components often resemble impellers. By employing 5-axis machining, manufacturers can ensure high precision in the design – critical for improving energy capture and performance.

Conclusion

5-axis machining is revolutionizing the production of impellers by offering unmatched precision, reduced setup times, enhanced surface finishes, and improved material efficiency. As industries continue to demand more complex geometries and higher performance standards, the role of 5-axis machining will become increasingly crucial.

Investing in this technology not only equips manufacturers to meet present demands but also prepares them for the future, where the need for advanced manufacturing techniques will only grow. By understanding and overcoming the challenges associated with 5-axis machining, companies can harness its full potential and stay ahead in the competitive landscape of modern manufacturing.

In summary, 5-axis machining is not just a manufacturing technique; it is a strategic advantage that can significantly elevate the quality and performance of critical components like impellers across various sectors.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.