In the contact process of various solutions, we have all found that the preliminary design always has a positioning. .

Positioner knowledge

1. The basic principles of the positioning on the side of the part

When positioning on the part of the room, the principle of 3 points is the most basic principle as a supporter. It is the same as the principle of the supporter. Of the 4 points, 3 points can determine a face, so a total of 4 faces can be determined, but regardless of positioning, it is quite difficult to make the fourth point in the same plane.

▲ 3 points Principles

For example, when using 4 positioners at a fixed height, only 3 points somewhere can be exposed to the room.

Therefore, when configuring the positioner, it is generally based on 3 points and the distance between these 3 points is increased as much as possible.

In addition, when the positioner is configured, the management charge management is required in advance. The management of the treatment load is also the direction of the handle / tool.

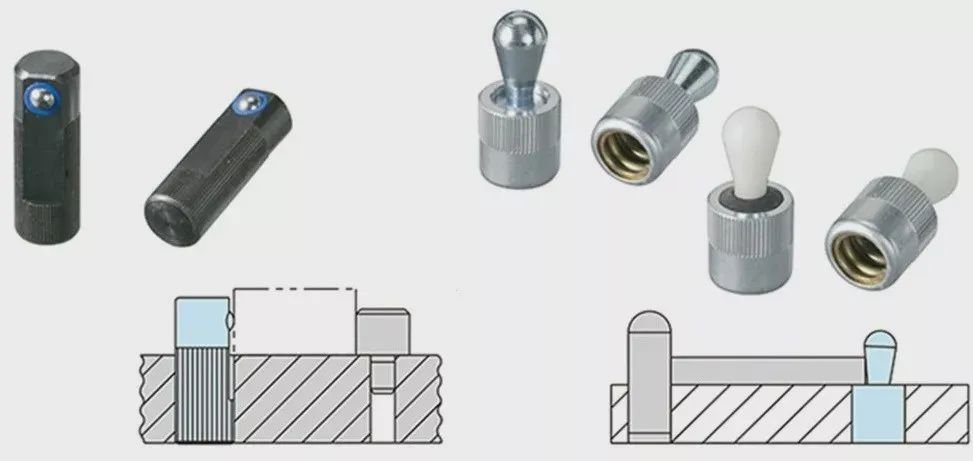

Generally, when the rough surface of the part is located, the adjustable positioning of the adjustable bolt -type positioning is located when the room treatment places are located and the positioner of the positioner (grinding) is used in the room.

2. Basic principles of positioning the holes in the part

When you locate the holes in the room processing process, you need to use tolerance sales to the positioning. Thanks to the accuracy of the hole in the part with the precision of the sales of the sub-orders, the combination of tolerance can ensure that the precision of positioning meets the real needs.

In addition, when you use the subpositioning of sales, a right pillar is generally used to sell and the other uses diamond-shaped sales, so that the installation and demolition part will become more practical, and it There will be few cases of parts and sales cards.

▲ Use sales positioning

Of course, it is also possible to use direct sales of the pillar by adjusting tolerance to tolerance. For more precise positioning, it is generally the most effective to use straight pillar sales and diamond -shaped sales.

When you use sales of direct pillars and sales of rhombes, the connection direction (contact with the part) of diamond -shaped sales is generally 90 ° with the connection between the sales of right pillars and sales in the form of diamond. work room.

Related knowledge of clampulizer

1. Classification of the tightening device

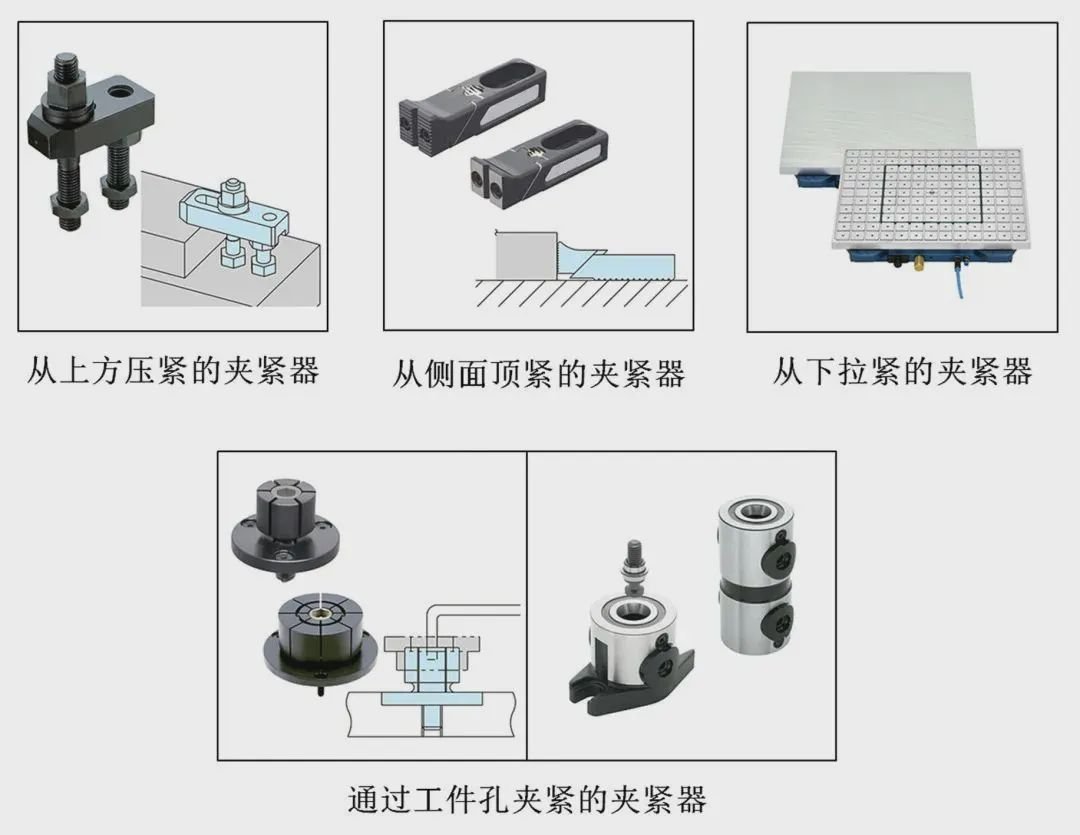

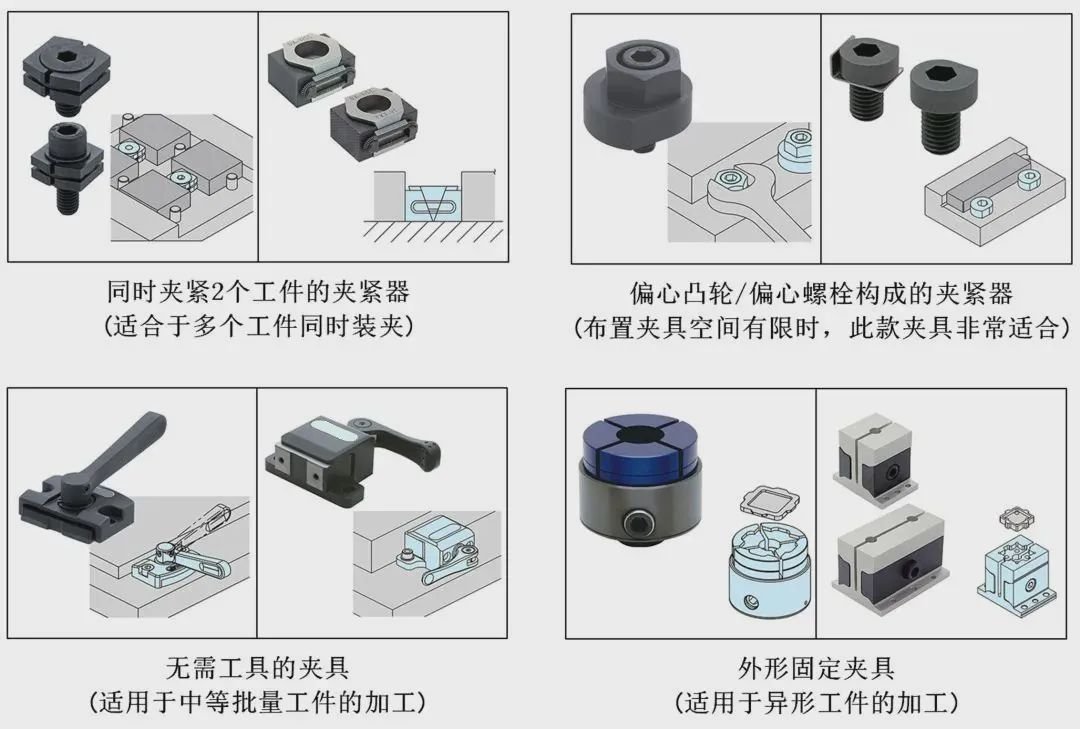

Depending on the tightening direction, it is generally divided into the following categories:

Then take a look at the characteristics of various pliers.

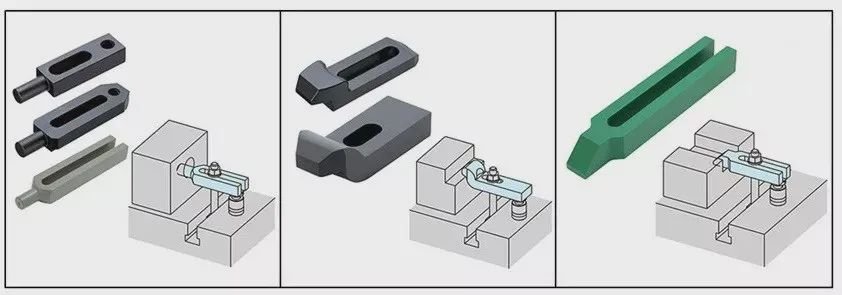

1. The tight tightening device from the top

The quantity of deformation when the compressor tightening is tight above the room, and the treatment of the part is the most stable. The most common clip of the room is the manual type lighting. For example, the figure below is called a “Pine -Leaf” turn signal. The tightening device made up of pressure plates, double -headed bolts, jack and nuts is called a “pine sheet” tightening device.

In addition, depending on the shape of the part, you can choose the piece of different shapes of different shapes depending on the shape of the room.

The relationship between the couple and the tightening force when tightening the tightening device of the pine leaves can be calculated by the bolt promotion force.

In addition to the tightening device for pine leaves above the room, there are similar pliers below.

2. Gramp the side tightening device

Originally, the tightening tightening method of the top parts was the most precise, and the part of the room treatment was also the smallest. However, it is necessary to treat the part or tighten the part above is not very appropriate. However, when the room is tight on the side, it will generate a floating force.

The tightening clip on the side also showed in the above figure.

The tightening clip on the side also has the similar tightening device.

3. The tightening device of the room tightening

When the thin-plaque room is treated on the surface, not only can be tightened from above, and it is unreasonable to press it on the side. When tightening the part below, if it is an iron part, a magnet tightening device can generally be used. When the metal parts not based on iron, you can usually use a vacuum suction cup to tighten.

In the two cases above, the size of the clamping force is proportional to the size of the part of the room and the complaint of the loving aspiration or the vacuum cleaner. If the treatment of small workers is too large, the treatment effect will not be ideal.

In addition, when you use a vacuum magnet or cup, the contact surface of the magnet and the vacuum suction settlement must be affected by a certain sweetness to be safe and normal.

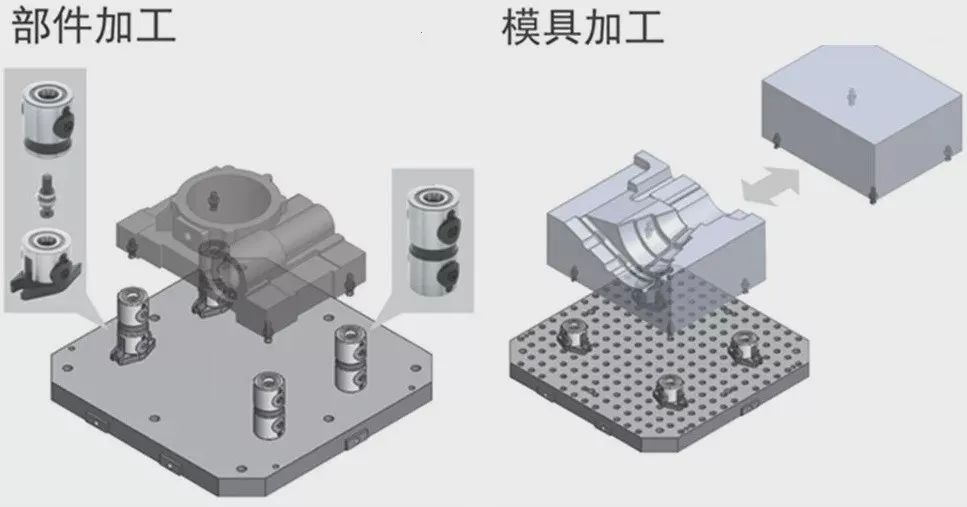

4. Use tightening of the hole hole

When you use a 5 -axis machining machine for multifaceted machining or the treatment of mold, in order to prevent the lighting and the tools from affecting treatment, it is generally suitable to choose a pore tightening method. Compared to the room tightening method and lateral tightening, the load generated by the room is smaller and the room can be deformed by the effective side.

▲ Use the hole to treat directly

▲ Define drawing nails to tighten it

Two, pre-classification

The above mainly concerns the file luminaire. When the part is adjusted vertically on the basis, the part will drop for reasons of gravity. For the moment, you need to use your hand to press the part to operate the tightening device.

▲ Pre-firm

If the part is large or most of the tightening simultaneous, the operability will decrease considerably and the clip time is also very long. Currently, the use of this Printemps type pre-glamping product can operate the working part of the tightening device in a distant state of state, which considerably improves operability and reduces the folding time of the room.

Third, the precautions when choosing a clamping

When you use a variety of tightening devices in the same job, be sure to be unified. For example, when the image at the bottom left is used to use a variety of tool spirit for the tightening operation, the overall load of the operator increases and the overall tightening time of the room will also become longer . For example, the lower right image is unified and the size of the tool wrench is also unified to facilitate the ON site operator.

▲ The operability of the part of the part

In addition, when configuring the tightening device, you must consider the operability of the part as much as possible. If the part should be tilted during installation, it is very annoying to operate.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.