We deal with processing every day and we often mention the accuracy of processing. But when you say precision, are you really right? Today, let’s focus on “machining precision”!

01

The difference between accuracy and precision

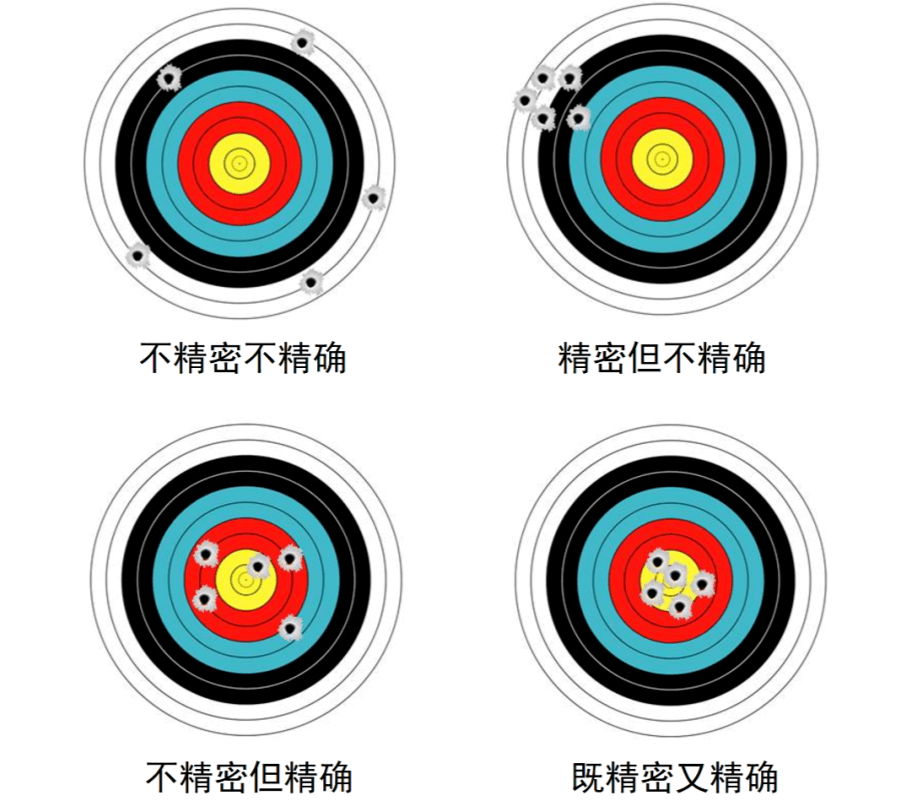

Accuracy indicates the correctness of the measurement results, and precision indicates the repeatability and reproducibility of the measurement results. Precision is a prerequisite for accuracy. The figure below is a good illustration of this.

Precision

Refers to the closeness between the obtained measurement results and the actual value. High measurement accuracy means that the system error is small when the average value of the measured data deviates less from the true value, but when the data is scattered, that is, the size of the accidental error is unclear.

Precision

It refers to the reproducibility and consistency between results obtained by repeated measurements using the same spare sample. It is possible to have high precision, but accuracy is not. For example, the three results obtained using a length of 1 mm are 1.051 mm, 1.053, and 1.052. Although they are highly accurate, they are inaccurate.

02

Definition of machine tool precision

When comparing CNC machine tools, if the “positioning accuracy” of machine tool factory A sample is marked as 0.002mm and the “positioning accuracy” of machine tool factory sample machine tools B is marked as 0.004 mm. Through these two intuitive data, you will naturally think that the machine tools of machine tool factory A are more precise than those of machine tool factory B.

However, in fact, it is very likely that the machine tools in machine tool factory B are more precise than those in machine tool factory A. The problem lies in their standards for defining precision. Therefore, when we talk about “accuracy” of CNC machine tools, it is important to clarify the definitions and calculation methods of standards and indicators.

Generally speaking, accuracy refers to the ability of the machine tool to position the tool tip relative to the program target point. However, there are many ways to measure this positioning ability and, more importantly, regulations vary by country.

European machine tool manufacturers:

European machine tool manufacturers, particularly German ones, generally adopt the VDI/DGQ3441 standard.

Japanese machine tool manufacturers:

When calibrating for “accuracy”, the JISB6201 or JISB6336 or JISB6338 standard is generally used. JISB6201 is generally used for general machine tools and ordinary CNC machine tools, JISB6336 is generally used for machining centers, and JISB6338 is generally used for vertical machining centers.

American machine tool manufacturers:

The NMTBA standard is generally used (this standard originated from a study by the American Machine Tool Manufacturing Association and was promulgated in 1968 and later revised).

When calibrating the accuracy of a CNC machine tool, it is essential to indicate the standards used. Using the Japanese JIS standard, the data is significantly smaller than using the German VDI standard or the American NMTBA standard.

Same indicator, different meaning

What is often confusing is that the same indicator name represents different meanings in different accuracy standards, but different indicator names have the same meaning. The above four standards, except the JIS standard, are all calculated using mathematical statistics after multi-turn measurements of multiple target points on the CNC axis of the machine tool. The main differences are:

1) Number of target points

2) Measure the number of revolutions

3) Approach the target point from one or two directions (this point is particularly important)

4) Methods for calculating accuracy and other indicators

This is a description of the main differences between the four standards. As expected, one day all machine tool manufacturers will uniformly follow ISO standards. This is why the ISO standard is chosen as a reference here. The following table compares 4 standards. This article only covers linear precision because the principle of calculating rotational precision is basically the same.

03

Thermal stability (effect of temperature on accuracy)

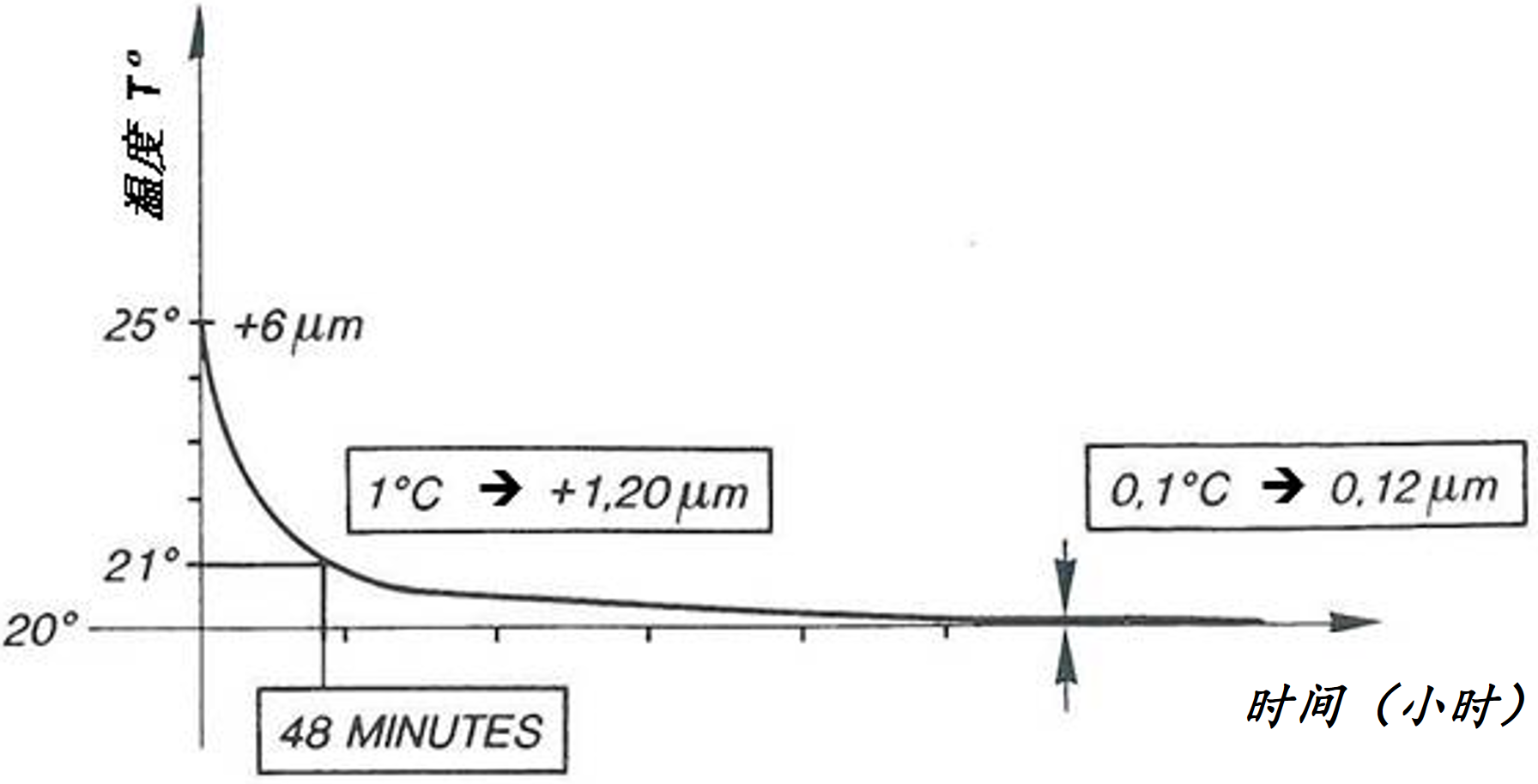

Steel: 100 x 30 x 20 mm

Size changes when temperature increases from 25℃ to 20℃: At 25℃, the size is 6 μm larger. When the temperature drops to 20℃, the size is only 0.12μm larger. It is even a thermally stable process. if the temperature drops quickly, an extended period of time is still required to maintain accuracy. Larger objects require more time to regain accuracy and stability as the temperature changes.

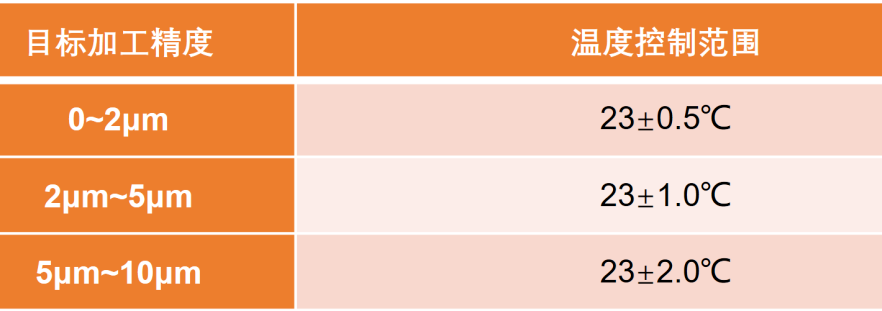

In high-precision machining, the temperature problem cannot be ignored, because temperature difference is the enemy of precision. Specifically, materials will expand due to thermal expansion and contraction. The linear expansion of the steel we use will produce a change of 12 μm per meter of length when the temperature changes by 1°C. This is true for all machines in every corner of the world.

Factories without precision machining experience often attribute unstable precision to equipment accuracy problems during precision machining. Factories with experience in precision machining know that this is basic common sense and will place great importance on the thermal balance between ambient temperature and machine tools. They know very well that even high-precision machine tools can only achieve stable processing precision under a stable temperature environment and thermal equilibrium state.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.