what isPAHT-CF? EveryoneI might think it has carbon fiber(CF) to high temperature (HT) nylon (PA), but this can be confusing. It turns out that PAHT has become a generic term for a range of polyamides.

HT means high temperature

picture1: A series of practical prints made using Bambu Lab’s PAHT-CF filament (Source: Bambu Lab)

One thing that manufacturers generally agree on is thatHT refers to high temperature. This shows that parts made from PAHT filaments can withstand high temperatures and maintain their mechanical properties.

From a technical point of view, you can expectTwo key areas of the PAHT datasheet have higher measurements: glass transition temperature (Tg) and thermal distortion temperature (HDT).

glass transition temperature(Tg) is the temperature at which a polymer begins to change from a rigid state to a more flexible state. Thermal deformation temperature (HDT) is the temperature at which a polymer begins to deform under a specific stress. It is also known as the deflection temperature under load (TgUL). Therefore, you will often see HDT temperatures combined with stress measurements such as 1.8 MPa.

What type of nylon does PAHT contain?

picture2:PAHT-CF filament, like that from Bambu Lab, is ideal for high temperature applications and can reach temperatures up to 194°C, much hotter than a cup of coffee (Source: Bambu Lab)

MiscellaneousSome technical data and properties of PAHT materials vary considerably due to the wide variety of nylons on which the material is based and the wide variety of blends of nylons with other polymers.

First, let’s see what nylon is. Most filament manufacturers use the termPA refers to nylon, whether PA6, PA66, PA11 or PA12. But more specifically, PA refers to a class of polymers called polyamides. All nylon is polyamide (PA), but not all polyamides are nylon.

So when it comes toWhen it comes to PAHT, PA can be PA6, PA66, PA11, PA12, or PPA which you may not have heard of (although some may argue that PPA isn’t even nylon in the strictest sense of the term).

Polyphthalamide(PPA) is a high performance polyamide with excellent thermal stability and chemical resistance. It usually, but not always, has higher tensile strength and stiffness than nylon 6, 66, 11 or 12. Another notable characteristic of PPA is that it has a higher Tg, melting point and strength at high temperatures higher than other nylons. In fact, it was once commonly referred to as “high temperature nylon”, so people may have thought PAHT was just another term for PPA.

“The term PAHT (high temperature polyamide) has emerged in the 3D printing industry in recent years, initially referring to PPA-based filaments,” said Mark Peng, founder of filament manufacturer Siraya Tech. “It should be noted, however, that the use of this term has become somewhat vague. Some manufacturers now use PAHT to describe filaments made from other high temperature resistant polyamides, such as PA12 (nylon 12) or PA6. These filaments strictly speaking, Silk is not a PPA.

Siraya Tech will launch a new PAHT-CF based on PPA at the end of November 2024, with a carbon fiber content of 25%. The product is called Core Black ($99/kg) and the carbon fiber is more abundant in the core of the filament, hence the name.

It should be notedBambu Lab produces a PAHT-CF, where the nylon is mainly PA12, but also just released a PPA-CF with higher HDT, strength and stiffness.

Polymer composition of PAHT-CF

picture3:

Therefore, yourPAHT can be a variety of nylons, or in the case of Bambu Lab and Luvocom, a blend of nylons, but how important is that really? Let us then examine the mechanical properties (strength, flexibility, impact resistance) of the different PAHTs.

Range of mechanical properties of PAHT

picture4:Chinese startupsPhaetus manufactures a range of hot, extruder and engineering grade polymer filaments, including this PAHT-CF (Source: Phaetus)

The mechanical properties of PAHT-CF should be closely related to the type of nylon it is based on and the carbon fiber content. For example, the tensile strength of PA6 (45-80 MPa) is generally lower than that of PPA (80-120 MPa), but the tensile strength of Luvocom, which is based on PA blend, is higher than that of QiDi Tech. , which is based on PPA.

The PAHT-CF has the following advantages:

High strength

High toughness

High rigidity

High impact resistance

chemical resistance

heat resistance

Wear resistance

matte finish

antistatic

ExcellentPrintAdaptability

For carbon fiber infused nylon,The Bambu Lab material also exhibits unusually high flexibility (elongation at break + Young’s modulus), which TDS says can be attributed to the base material being PA12 and “other long-chain PAs.”

All these different measurements highlight the fact that filament is a mixture of materials and no two recipes are the same, which is why having a complete rangeTDS is so important.

Therefore, if different brandsPAHT-CF has different properties, so what do they have in common or why is PAHT-CF even used?

Figure 5

Really attractive properties of PAHT-CF

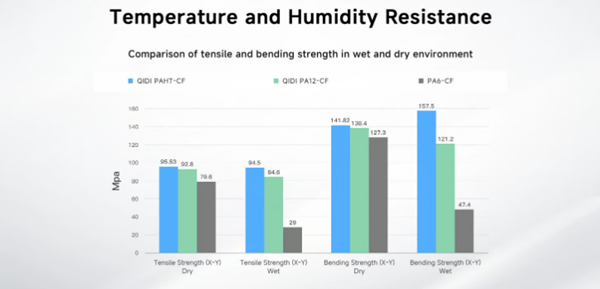

picture6:Qidi Tech’s wet and dry nylon filament comparison chart shows PAHT’s resistance to the generally harmful effects of moisture (Source: Qidi Tech)

Bambu Lab stopped production of PA-CF in 2022 and switched to PAHT-CF, which other filament manufacturers often compare to PA-CF to highlight one main attribute: extremely low moisture absorption.

If you don’t like dry materials, you probably won’t be successful with any type of nylon.

It is generally recommended to keep nylon dry and dry before use as it easily absorbs moisture from the air. Even after drying, nylon left in a humid environment is difficult to recover.PAHT is a more moisture tolerant nylon. It absorbs up to 50% less water than regular PA-CF, but that doesn’t mean you’ll never need to dry PAHT. Staying dry is always recommended.

Be careful not to overdry the nylon, however. Peng points out that if the filament is already dry, leaving it at high temperature for several hours can causeThe PPA crystallizes, as during annealing. This may make printing too difficult.

“The importance of keeping nylon/PAHT dry cannot be overstated,” says Peng. “In order to effectively remove moisture, the temperature must be kept above 100°C for several hours, but most filament dryers on the market can only reach a maximum temperature of 70°C, which is probably not suitable for drying PA filaments. Words are not enough. »

This is why if you do not have the necessary equipment to effectively eliminate humidity, keepThe dryness and tightness of the PAHT are essential.

In addition to moisture resistance, andPAHT parts can certainly withstand higher temperatures than PA-CF, but the mechanical properties will also vary depending on the type of PA used.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.