Mastering CNC Milling Time Calculation: A Comprehensive Guide to Accurate Manufacturing

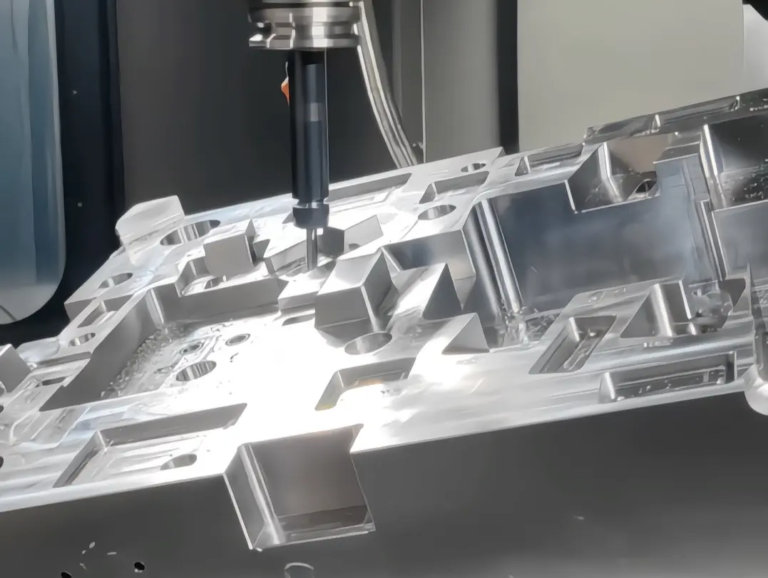

In the world of precision manufacturing, understand CNC milling time It’s not just about scheduling a schedule, it’s about efficiency, cost control and delivering high-quality parts on time. As a professional five-axis CNC machining manufacturer, Greatlight Outhime Lover of Advanced equipment and proprietary technology optimizes every minute of machining. In this guide, we will break down how to accurately calculate milling times and share industry-tested strategies to accelerate production without compromising accuracy.

Why is CNC milling time important

Accurate time estimates are the backbone of project planning. If you underestimate, you may delay and overspent; if you overestimate, you will lose competitiveness. For complex projects, especially those that require five-axis functionality – the definite calculation ensures:

- Cost predictability: Manual, machine time and tool wear directly affect pricing.

- Resource allocation: Effective planning for multi-part batches or emergency orders.

- quality assurance: rush work leads to errors; optimization time maintains consistency.

Key factors affecting CNC milling time

- Part complexity and geometry:

- Simple 2D profiles and intricate 3D surfaces such as aerospace impellers require very different approaches. The five-axis machine performs excellently by reducing complex angle settings.

- Material properties:

- Hard metals (such as titanium) require slower feed, which increases time. Soft materials (such as aluminum) can be processed aggressively.

- Machine functions:

- Our five-axis CNC machine eliminates pauses in repositioning, reducing non-cut time by up to 70% compared to the 3-axis alternative.

- Tools and strategies:

- Tool changes, tool path efficiency (e.g., Trochoidal milling vs. conventional), and tool life can affect the total duration.

- Cutting parameters:

- Cutting speed (SFM),,,,, Feed rate (IPM)and Depth of cutting (DOC) Speed and tool integrity must be balanced.

Step-by-step CNC milling time calculation

Formula Foundation:

[

\text{Machining Time (min)} = \frac{\text{Total Tool Path Length (in.)}}{\text{Feed Rate (in./min)}}

]

Step 1: Break the parts

- Divide the operation into rough, semi-fixed and completed. Calculate each separately.

example: Turbo blades may involve:

- Rough: 80% material removal.

- Finishing: 20% of critical surfaces.

Step 2: Determine the feed speed and cutting speed

- Use material-specific guidelines (e.g., aluminum is 600–1,200 SFM).

- Feed rate (IPM) = rpm × flute × chip load (IPT).

- Explain radial/axial participation adjustment.

Step 3: Calculate the path length

- CAM software (such as MasterCam or Siemens NX) measures accurate tool travel. For manual estimation:

- Direct circuit: direct measurement.

- Contour: Use the circumference/arc formula.

Step 4: Factors of Uncut Time

- include:

- Tool changes (average change of 5-15 seconds).

- Workpiece repositioning (eliminated with five-axis setting).

- Fix and detect.

Step 5: Simulation Verification

- Modern cam tools simulate machining, identify collision and refining time estimates to ±5% accuracy.

How Greatlight optimizes milling time with five-axis technology

- Reduced settings:

- Single-piece machining of complex parts reduces idle time and human error.

- Dynamic tool path:

- Adaptive cleaning: High quality driving rate for lower tool stress.

- Continuous 5-axis tool path: Keeping the optimal tool orientation minimizes air cutting.

- Tool lifespan:

- The strategic use of ceramic end mills in high-speed alloys increases tool life, thereby reducing the frequency of change.

Our production location cost-saving tips

- Batch processing: The machine has multiple parts in a cycle.

- Mixed additives/subtraction: For near mesh parts, reduce the amount of initial material.

- Predictive maintenance: Avoid using IoT-enabled machines to monitor unplanned downtime.

in conclusion

Precision CNC milling time calculations combine science and experience. By mastering variables such as tool dynamics, material behavior, and advanced kinematics (especially in five-axis machining), manufacturers unlock unparalleled efficiency. At Greatlight, we combine cutting-edge machinery with deep technical expertise to deliver precise parts at faster, more refined and competitive prices. Whether you are prototyping or expanding production, Work with us Seamlessly blend speed, accuracy and cost-effectiveness.

[CTA] Ready to optimize your project? Get instant quotes and DFM analytics on Greatlightcnc.com

FAQ: CNC milling time explains

Question 1: Can five-axis CNC really reduce milling time?

Absolutely. By machining complex geometry in a single setup, the five-axis eliminates 60-80% repositioning time and reduces cumulative errors.

Q2: How does material selection affect time?

Harder materials (e.g., inappropriate) require slower feed/speed, extending time by 2-4 times with aluminum. We use specialized tool coatings and high pressure coolant to mitigate this.

Question 3: Why is the time estimate of my cam inaccurate?

Simulation can ignore machine acceleration/deceleration or tool elasticity. We cross-verify through machine detection and historical working data.

Question 4: What is the “hidden” time in milling?

Non-cutting activities (settings, tool changes, checking) consume 30% of the total working time, which is featured through automation and our multi-piece system.

Question 5: Can I speed up milling acceleration without buying a new machine?

Yes. Optimize feed/speed with our free DFM guide, convert to efficient tool paths, or leverage our subcontracts for complex operations.

Please trust the great highlights because you can design accuracy on time every time. Contact our team today to bring your design to life.