Production must be faster, parts must meet higher requirements and our current achievements must still be surpassed. To do this, manufactured products must be optimized in some way to increase efficiency. Often, this means reducing the weight of parts while seeking greater strength and performance. ThisThe “less is more” equation starts at conception! As designers strive to design in this direction, new technologies such as artificial intelligence and machine learning offer new possibilities, as do topology optimization and generative design.

Topology optimization and generative design are two methods that use computer-aided calculations to optimize a design, making it completely efficient on the one hand and saving costs and production resources on the other, to name a few just a few. Although these two approaches pursue similar objectives, they should not be equated or confused. Below we explain the meaning, benefits, challenges, specific application areas and examples of topology optimization and generative design, and explain how they relate toThe usefulness of combining 3D printing.

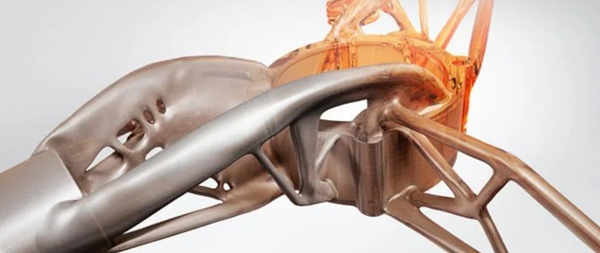

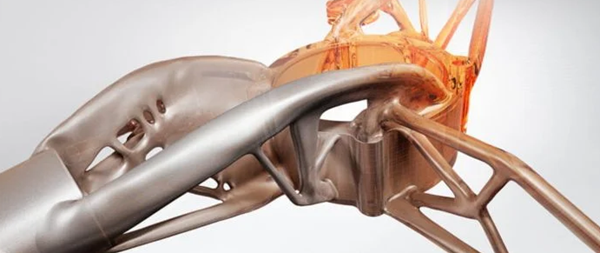

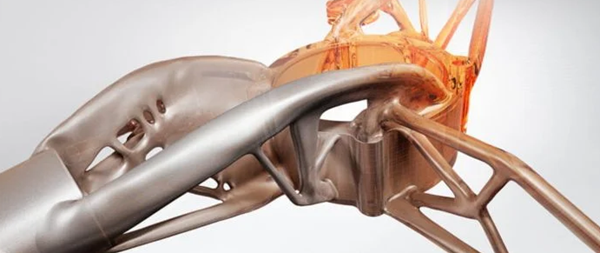

Photo credit:Man and machine

Get to the best design faster with topology optimization and generative design

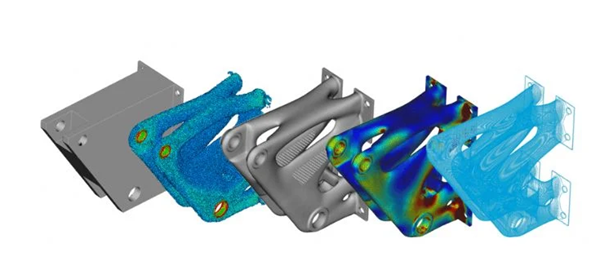

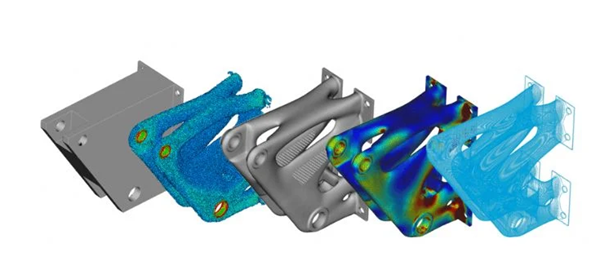

Topology optimization itself is not a new method, sinceIt has been used since the early 1990s to optimize 3D models, retaining basic functionality while saving material when the part does not need to support loads. Topology optimization always starts with a user-friendly design, which must be adjusted so that performance does not degrade without sacrificing cost. However, to do this, it is necessary to define certain framework conditions, such as taking forces into account and defining protected areas. Computer algorithms then create a mesh model whose structural integrity must be verified during a finite element analysis (FEA) process. The CAD engineer must then check and possibly adjust the results.

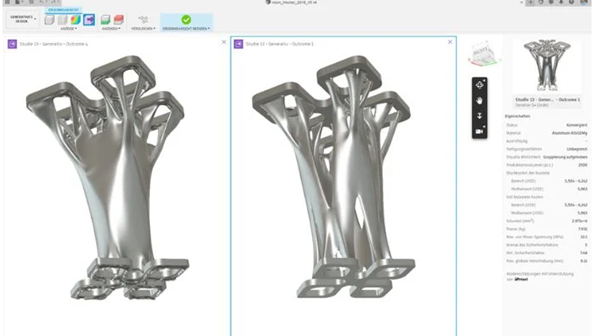

While the final design after topology optimization always precedes previously established concepts that require improvement (usually in terms of materials and weight), generative design does not require baseline design. That’s a significant difference. In generative design, define“Constraints” (conditions) to create as many new designs as possible to explore multiple possibilities. These limitations may be the surface area of the barrier, the materials used, the manufacturing process chosen, the cost, etc. The AI can then imagine different design possibilities that correspond to previously defined parameters. It is worth mentioning that generative design does not guarantee the best solution from the start, but rather examines possible trade-offs between the set goals (such as weight, material consumption and cost) and offers several options based on preferences of the user. Therefore, as with topology optimization, engineers must first define these conditions and finally select the final design from countless possibilities.

Comparison between Topology Optimization and Generative Design (Image source:Man and machine)

Both solutions enable the use of computer-aided mechanisms for product development and optimized design in terms of lightweighting, cost reduction and material savings. while maintaining or improving the quality of the components. It is also worth adding that the creations presented are always inspired by natural events, with similarities to skeletal structures, beehives, corals, etc. While topology optimization results in a single final design, generative design offers multiple possibilities based on defined constraints.

Therefore, topology optimization and generative design work in different ways to create optimal designs that may create challenges in the next phase of production. Not all manufacturing processes are capable of implementing complex designs with nested geometries, overhangs, and varying wall thicknesses that are sometimes recommended as part of optimization.

This is why the potential of these two tools works particularly well withUsed in conjunction with 3D printing. On the one hand, because both solutions result in designs that are impossible or difficult to achieve with conventional processes, and on the other hand, because designs can be generated based on manufacturing methods. In the case of generative design, it is possible to determine from the start that the part will be manufactured via additive manufacturing, and the software will take this condition into account and therefore only generate solutions that are feasible using 3D printing technology. This is not the case for topology optimization. CAD engineers must verify the resulting design and possibly improve it based on the manufacturing method. For example, if the part is manufactured by 3D printing, support structures may be required, depending on the method used. The design engineer must then determine where and how they should be placed.

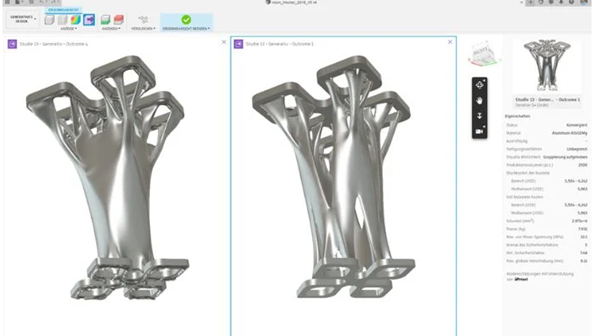

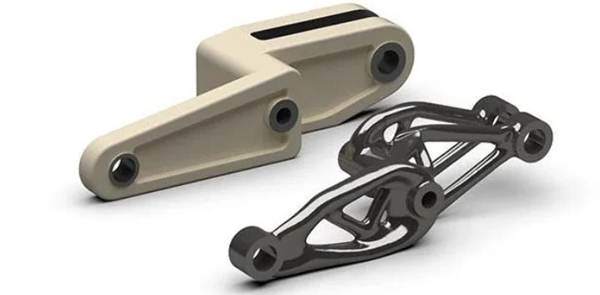

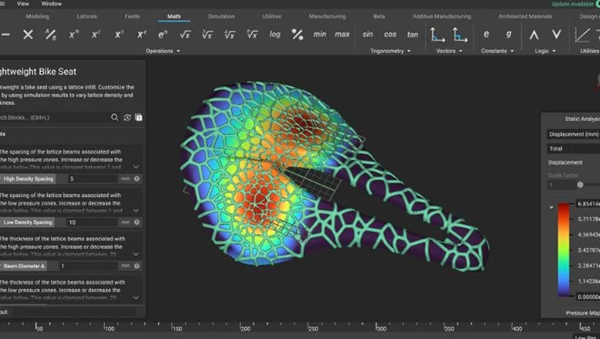

Optimization via generative design can be achievedRepresentation of 3D printed parts. (Image source: Siemens PLM)

Advantages and limitations

One advantage of both approaches is that the design can be optimized based on parameters defined using algorithms or artificial intelligence. This saves time, material and therefore costs. Generative design allows you to create hundreds or even thousands of design options and compare them to each other without wasting time. Simulation and testing are now part of the design process, avoiding costly rework. Cost can also be defined as a condition of generative design, whereas topology optimization of component concepts does not provide cost information.

The multiple design possibilities in generative design can be an advantage for demonstrating different solutions. With topology optimization, there is only one final design. In this case, the engineer still needs to improve and verify, whereas when using other tools, he uses his expertise to make choices. A key advantage is that at the end of the generative design process, the design can be exported as a file.STEP files for example to manufacture parts via additive manufacturing and simplify the rest of the production chain. . The model obtained through topology optimization must first be converted into a CAD file.

While both computer-aided design solutions have many advantages, they also present some challenges. On the one hand, software solutions for generative design and topology optimization are very expensive, and on the other hand, their correct and efficient use requires specialized knowledge. Topology optimization is already a proven method and many large companies have become familiar with it over the years. Generative design, on the other hand, has only become possible and popular in recent years. Although generative design software may find more solutions, it is not yet very common.

Topology optimization is mainly used to increase the weight of parts (Image source:form laboratories)

For both processes, it is inseparableCAD designers and their expertise. They must study material properties and manufacturing techniques and analyze the feasibility of the design. The end use must also be considered during the design process. AI-created designs may be optimal in terms of functionality, but they often don’t look good. If necessary, designers must make adjustments to the aesthetic, tactile, auditory and olfactory aspects, because these sensory stimulations are decisive for the end user of the product. It is at these sensory points that topology optimization and generative design reach their limits and cannot yet replace humans in the design process. Nevertheless, both design solutions open up a wide range of possibilities in many applications.

Areas of application

Although several application areas often overlap, the approaches and applications of these methods differ. By removing matter from a given base shape, bothFEA simulations aimed at improving performance and optimizing topology always take place within defined limits. Generative design, on the other hand, goes a little further. It uses algorithms to develop new creative solutions that not only optimize material distribution, but also expand the design space. Topology optimization and generative design are suitable not only for fields where the physical properties of components are crucial, such as aerospace or automotive, but also for creative fields and architecture.

AirbusPart of the A320, developed using generative design. (Photo credit: Autodesk)

In aerospace, topology optimization helps improve existing designs to produceaircraft structures, such as stiffeners, which help reduce fuel consumption. Take for example the work of Andreas Bastian. The airplane seat he designed reduced weight by 54%, significantly reducing the overall weight of the plane. But companies like Airbus are also using generative design to make more powerful parts and creative assemblies. A famous example is the Airbus A320 bulkhead, inspired by natural growth processes.

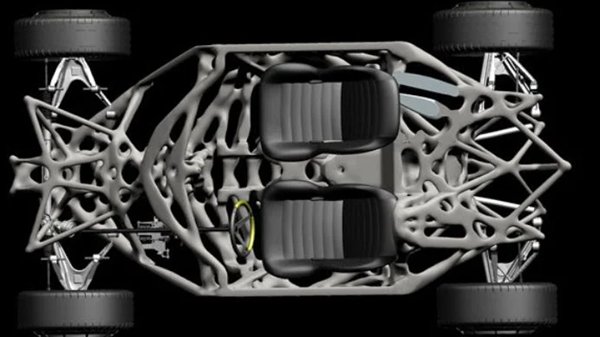

In the automotive industry, topology optimization improves existing designs by reducing weight, helping to develop lightweight, stable and safe vehicles. Since it will exceedWith 12 different components integrated into one piece, Fiat Chrysler’s suspension system has been reduced by 36 percent. Generative design is also used to optimize automotive components by creating new solutions. It allows companies to improve the performance of their products and meet increasing environmental requirements. For example, Bugatti used generative design software to develop the Chiron’s wing control system, which optimized assembly and reduced weight by more than 50 percent. But Porsche also used a derivative design to create innovative pistons for the 911 GT2 RS’s high-performance engine.

Vehicle design developed using generative design. The similarity to the skeletal structure is particularly striking here, and future optimized vehicles could resemble them. (Image source: Siemens)

In the medical field, our two modeling tools also play a decisive role. An example application of topology optimization isNuVasive’s custom implants, which use a lattice structure to reduce weight without compromising stability. In contrast, generative design enables advanced solutions, particularly in the area of osseointegration, where implants are designed to resemble the structure of natural bone. This promotes the growth of new bone tissue on the 3D printed implant, improving long-term stability. While topology optimization in the medical field generally aims to improve efficiency and reduce weight, generative design focuses on optimal adaptation to each patient’s anatomy, especially when manufacturing patient-specific prostheses. patient.

Additionally, generative design is used in architecture and construction to create new and functional space concepts while providing solutions to complex design problems. Topology optimization is also increasingly used in construction to improve the shapes of existing buildings and increase the load-bearing capacity. Both methods allow architects to design more efficient structures from the design stage, often taking inspiration from natural structures.One example is MX3D’s bridge, which was built over a canal in Amsterdam using generative design.

Generative design is mainly used in the fashion and jewelry industries, as there is less focus on optimizing factors such as weight and more on creating creative and original shapes. designerJulia Körner is one example: she designed innovative 3D printed costumes for the hit film Black Panther. Anouk Wipprecht also uses generative design, such as her ScreenDress, which is then created using MultiJet Fusion technology. The most important thing here is to push the boundaries of traditional fashion and use digital design processes to create new aesthetic structures.

On the left isDress designed by Anouk Wipprecht, on the right a dress designed by Julia Körner. (Photo credit: Anouk Wipprecht, Julia Körner)

Software and vendors

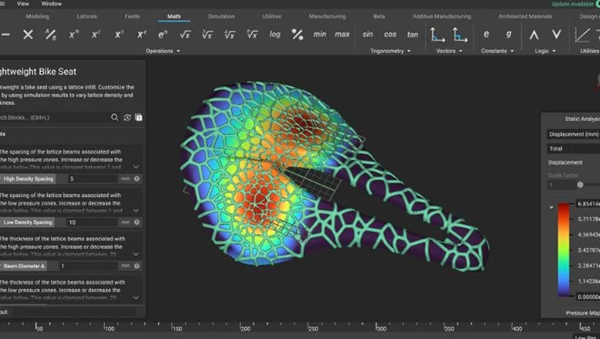

To effectively use topology optimization and generative design, specialized software solutions are required. For topology optimization,Tools such as Oqton’s 3DXpert are ideal, especially for implants and complex geometries. But Altair Inspire is also ideal for applications in the automotive and aerospace sectors. Ansys Discovery and Netfabb also provide topology optimization support to ensure stable 3D printing. Netfabb also offers a free trial, otherwise the price is €5,300 for one year or €15,895 for three years. Another software solution is ParaMatters’ CogniCAD, a cloud platform that combines topology optimization and generative design and specializes in complex 3D structures. To use CogniCAD, you can purchase tokens, which range in price from $14.90 to $5.90, depending on the software version you choose.

Z88Arion® is free software with three optimization algorithms for topology optimization. The Siemens NX-12, for its part, stands out for the integration of topological optimization based on convergent modeling technology, which allows perfect 3D modeling and results in lighter but stronger components. This software is suitable for generative design and topology optimization.

nTpo is software adapted to generative design. (Photo credit: nTopologie)

For generative design,nTopology offers the powerful nTop software, which provides generation tools to meet individual needs. Autodesk’s Fusion 360 is also a good choice, with features like sketching, surface modeling and rendering, and can be used for topology optimization and generative design. Other software includes Creo Parametric and Creo Generative Design, which use cloud technology to create optimized design concepts and quickly implement cost-effective designs. Another software solution is Hexagon’s MSC Apex Generative Design, suitable for creating detailed and complex structures; or Cognitive Design, which will allow you to quickly obtain optimized designs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.