Researchers from the Royal Melbourne Institute of Technology (RMIT University) in Australia, in collaboration with the Czech group Tescan and the University of North Texas in the United States, have developed a new bainitic titanium alloy (Ti-Cu-Fe). This advancement is expected to significantly improve the quality and performance of parts produced using additive manufacturing technology, particularly in industries that require high-strength materials.

Advances in Alloy Design for Additive Manufacturing

The research, published in Materials & Design, focuses on using component supercooling to suppress coarse columnar grain growth in Ti-Cu-Fe alloys, which is a key issue in titanium alloys made from additive manner. This process promotes the formation of fine equiaxed crystal structures, which is crucial for improving the mechanical properties of the material.

The researchers used a specific additive manufacturing technology, directed energy deposition (DED), to successfully control the solidification microstructure. This method produces a bainite microstructure characterized by the α phase, the TiCu intermetallic phase and a retained β phase matrix. This microstructure is extremely beneficial in increasing the strength and durability of the material, making it more suitable for demanding applications.

Innovative bainitic titanium alloy for additive manufacturing

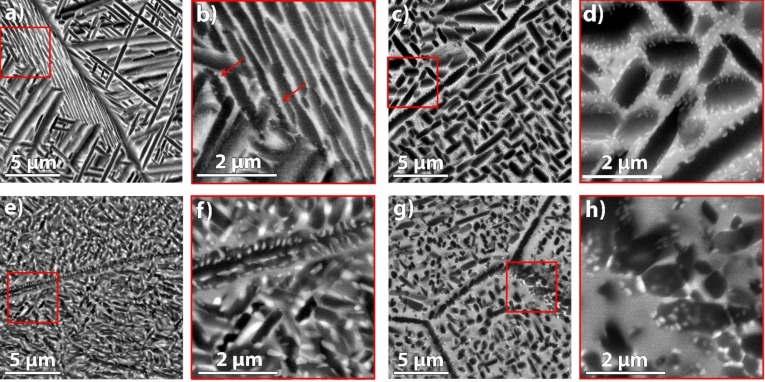

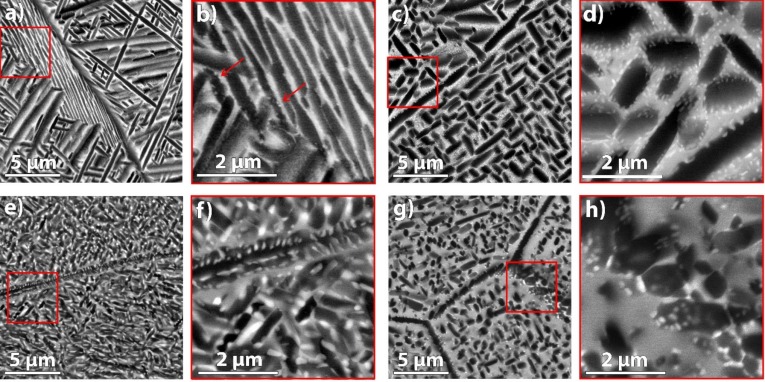

Microstructural analysis of Ti-Cu-Fe alloy produced by directed energy deposition (DED). Figures a) and b) show Ti-2Cu-4Fe, where the red arrows indicate Ti2Cu particles. Images c) and d) show Ti-4Cu-4Fe, while images e) and f) show Ti-6Cu-4Fe. Finally, figures g) and h) show Ti-4Cu-6Fe. The red frame marks the enlarged area in the adjacent image. In these microstructures, the darker particles/laths represent the α phase, the gray matrix is the β phase, and the brighter particles are the Ti2Cu intermetallic phase. (Image source: “Materials and design”)

Potential applications and future research

The Ti-Cu-Fe alloy system developed by the researchers is expected to further improve mechanical properties through grain boundary engineering and the introduction of additional nucleation sites. This potential improvement could lead to the production of stronger parts.

This research is of great importance, especially in fields such as aerospace, automotive and biomedicine, where high-performance materials are essential. Combining inexpensive elemental powders with advanced manufacturing techniques such as directed energy deposition can also make the technology more accessible and cost-effective.

final thoughts

Overall, the development of these new bainitic titanium alloys represents a major advance in the field of additive manufacturing. By solving key challenges related to the microstructure of additively manufactured parts, this research opens new possibilities for creating materials with excellent mechanical properties. As the field of additive manufacturing continues to evolve, innovations like this will play a key role in shaping its future.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.