The concept of rheology refers to the branch of physics that studies fluids. More specifically, it analyzes the behavior of materials when they flow or deform, that is, how they react to applied forces or stresses. Although rheology is applicable to a wide range of scientific and engineering disciplines,In the context of 3D printing, it has become critical for certain manufacturing technologies. It makes it possible to understand and control the behavior of the materials used, such as plastics or hydrogels, during the successive superposition of layers.

This branch of physics was founded by EugèneIntroduced by Eugene Bingham and formed independently in 1930. Etymologically, the word rheology comes from the Greek rheo, meaning “flow”, and logos, meaning “science”. In simple terms, rheology describes the deformation and flow of materials under various stress conditions. Therefore, rheological materials can be classified based on their behavior when subjected to different forces. We distinguish between elastic solids, which are solids which retain their shape after deformation, and viscous fluids, which flow continuously under the action of a force. Finally, we discovered viscoelastic fluids, which are materials combining the properties of elastic solids and viscous liquids. This is the case for polymers used in 3D printing.

A thorough understanding of rheology ensuresQuality of 3D printed parts

Rheology inImportance in 3D printing

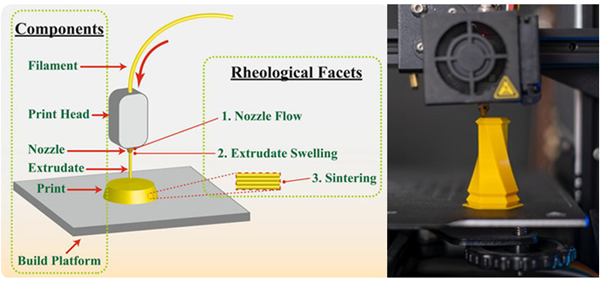

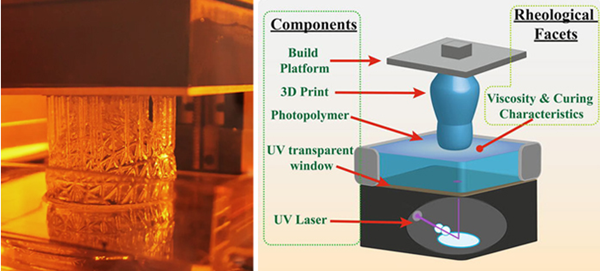

Rheology for3D printing is essential for describing the behavior of polymer materials when deposited on a print bed, whether by extrusion or polymerization. Understanding the rheology of these plastics allows us to predict their behavior during the printing process, which is essential to ensure the quality and precision of the final part. Indeed, the rheological behavior of the material during the printing process directly affects all aspects of the process and the quality of the printed parts. The reasons why we find rheology essential in 3D printing include:

Viscosity control:In extrusion and resin processes, there must be a precise balance between the viscosity and elasticity of the material. In both cases, the viscosity of the material directly affects its flowability and the quality of the final part. If the viscosity is too high, the material will be difficult to extrude or deposit, resulting in clogging, plugging or uneven distribution, resulting in defective parts. Conversely, if the viscosity is too low, the material may flow too easily, causing unwanted buildup, distortion, or lack of layer definition. Rheological studies and appropriate adjustments of process conditions such as temperature and extrusion speed help optimize material flow.

Rheology in extrusionSearch for 3D printing applications

Reduce flow and spills:In material jetting technology, resin is sprayed onto the print bed and the rheology prevents the material from flowing or spilling. If the rheology of the resin is not appropriate, the deposition may be poor. The viscosity of the material must be low enough to flow properly, but high enough to prevent the material from flowing or spilling.

Interlayer adhesion:One of the challenges of 3D printing is ensuring that each printed layer adheres properly to the previous layer. This largely depends on the rheological properties of the material. The latter must be sufficiently viscous so that the newly deposited layer maintains its shape and does not flow excessively. It should also be viscoelastic, allowing the layer to melt and adhere well to the previous layer. This is particularly important for high-resolution prints and parts with complex geometries.

Dimensional stability and post-processing:After printing, many materials are subject to warping, especially as they cool and solidify. These deformations, such as warping or shrinkage, can affect the quality and accuracy of the part. Rheology can predict how the material will behave as it cools, allowing printing conditions to be adjusted to minimize these issues.

Rheological analysis applied to resins3D printing

Development of new materials:Rheology research3D printing plays a key role in new composite materials. These include materials with specific properties, such as high heat resistance, increased flexibility or reduced deformation upon cooling. Rheological characterization helps predict the behavior of these materials during the printing process, ensuring their suitability for technology and applications in various industries.

As we have seen, rheology is a polymerKey terms to consider in 3D printing. Whether controlling material flow, improving interlayer adhesion, or minimizing deformation, understanding the rheological behavior of a material can help optimize each step of the additive manufacturing process. This knowledge is crucial not only to guarantee the quality of printed parts, but also to develop new materials whose properties expand the possibilities of 3D printing in the industrial sector.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.