CNC Machining vs 3D Printing: A Comprehensive Guide to Modern Manufacturing Technologies

Introduction

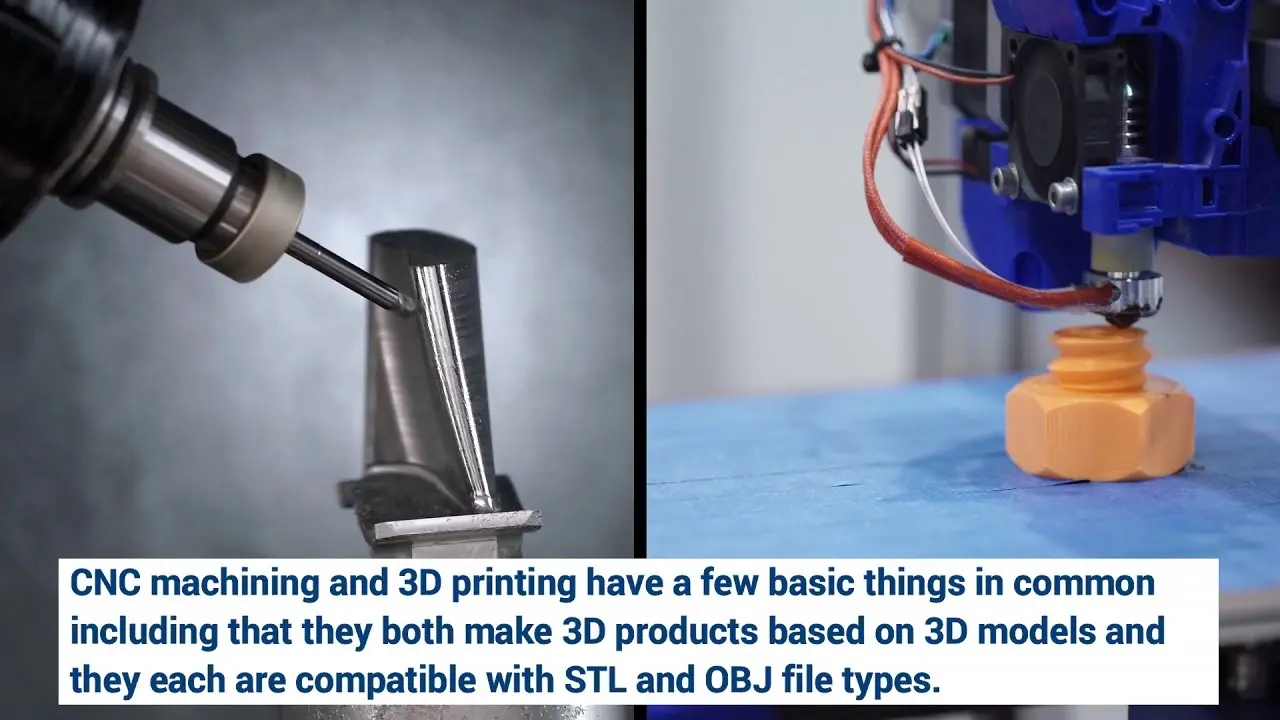

In today’s rapidly evolving manufacturing landscape, two technologies stand at the forefront of production: CNC (Computer Numerical Control) machining and 3D printing, also known as additive manufacturing. While both technologies create physical objects from digital designs, their approaches, capabilities, and ideal use cases differ significantly. This comprehensive guide explores the key differences between these revolutionary manufacturing methods.

Understanding the Basics

What is CNC Machining?

CNC machining is a subtractive manufacturing process where material is systematically removed from a solid block (known as a blank or workpiece) until the desired shape is achieved. Computer-controlled cutting tools perform precise movements to create the final product, following detailed instructions generated from CAD (Computer-Aided Design) files.

What is 3D Printing?

3D printing, in contrast, is an additive manufacturing process where objects are created by depositing material layer by layer according to a digital blueprint. This technology has revolutionized prototyping and small-scale production by enabling the creation of complex geometries that would be impossible or prohibitively expensive using traditional manufacturing methods.

Production Efficiency and Cost Considerations

Speed and Batch Size Optimization

3D Printing Advantages

- Ideal for rapid prototyping and small production runs

- No tooling or setup costs for new designs

- Quick turnaround for one-off custom pieces

- Minimal operator intervention required during production

CNC Machining Advantages

- Superior efficiency in large-scale production

- Faster production of simple geometries

- Consistent output quality across large batches

- Lower per-unit costs in mass production

Cost Analysis

Initial Investment

- 3D Printing: Higher initial equipment costs for industrial-grade machines

- CNC Machining: Substantial investment in machinery, tools, and facilities

Operating Costs

- 3D Printing: Higher material costs but minimal waste

- CNC Machining: Lower material costs but significant waste generation

Quality and Precision Considerations

Surface Finish and Accuracy

CNC Machining Capabilities

- Exceptional surface finish quality

- Precision tolerances as tight as ±0.0005 inches

- Consistent quality across production runs

- Superior strength in final products

3D Printing Characteristics

- Layer lines may be visible without post-processing

- Typical tolerances of ±0.005 inches

- Variable strength depending on print orientation

- May require surface treatment for optimal finish

Design Flexibility and Manufacturing Constraints

Geometric Freedom

3D Printing Advantages

- Creation of internal channels and hollow structures

- Complex geometries without additional cost

- Integrated assemblies printed as one piece

- Unlimited design iteration potential

CNC Machining Considerations

- Tool access requirements limit internal features

- Complex geometries increase cost and time

- Multiple setups needed for complex parts

- Design modifications may require new programming

Material Compatibility and Properties

Material Selection

CNC Machining Materials

- Metals (aluminum, steel, titanium)

- Plastics (delrin, PEEK, nylon)

- Wood and composites

- Exotic materials and alloys

3D Printing Materials

- Thermoplastics (PLA, ABS, PETG)

- Photopolymers

- Metal powders

- Ceramics and composites

Material Properties and Performance

CNC Machined Parts

- Consistent material properties

- High strength and durability

- Excellent heat resistance

- Superior wear characteristics

3D Printed Parts

- Anisotropic properties

- Variable strength based on print parameters

- Limited heat resistance

- Potential for porosity issues

Environmental Impact and Sustainability

Waste Generation and Resource Usage

3D Printing Environmental Considerations

- Minimal material waste

- Lower energy consumption

- Potential for recycled materials

- Reduced transportation needs

CNC Machining Environmental Impact

- Significant material waste

- Higher energy consumption

- Cutting fluid disposal requirements

- Potential for material recycling

Industry Applications and Future Trends

Current Applications

3D Printing Sweet Spots

- Medical devices and implants

- Aerospace components

- Architectural models

- Custom consumer products

CNC Machining Ideal Uses

- Automotive components

- Industrial machinery

- Precision instruments

- High-strength structural parts

Future Developments

Emerging Technologies

- Hybrid manufacturing systems

- Advanced materials development

- Improved automation

- Enhanced software integration

Making the Right Choice

Decision Factors

- Production volume requirements

- Geometric complexity

- Material specifications

- Cost constraints

- Quality requirements

- Time considerations

Recommended Applications

Choose 3D Printing When:

- Prototyping new designs

- Producing complex geometries

- Creating customized products

- Manufacturing small batches

- Time-to-market is critical

Choose CNC Machining When:

- High precision is required

- Producing large volumes

- Using traditional materials

- Surface finish is critical

- Strength is paramount

Conclusion

Both CNC machining and 3D printing have revolutionized modern manufacturing, each offering unique advantages and limitations. Understanding these differences is crucial for making informed decisions about which technology best suits specific production needs. As these technologies continue to evolve, their capabilities will expand, potentially leading to more hybrid approaches that combine the best aspects of both methods.

The key to successful manufacturing lies not in choosing one technology over the other, but in understanding how to leverage the strengths of each process for optimal results. By carefully considering factors such as production volume, design complexity, material requirements, and cost constraints, manufacturers can make informed decisions that maximize efficiency and product quality while minimizing costs.

To sum it up in the simplest terms from an industry insider: use CNC machining for high-precision requirements, and use 3D printing for less-demanding precision.