Pioneering Breakthrough: Unveiling the Power of Photopolymerization for Cutting-Edge Lithography and 3D Printing Technologies

The realm of additive manufacturing and 3D printing continues to revolutionize various industries, including healthcare, aerospace, and electronics. However, the limitations of current techniques have hindered the widespread adoption of these technologies. To overcome these hurdles, researchers at the Autonomous University of Barcelona (UAB) have made a groundbreaking discovery – a novel photocûtur (photo-induced chemical reaction) to form solid polymer networks, paving the way for improved lithography and 3D printing with unprecedented precision and efficiency.

The Challenges of Current 3D Printing Technologies

Traditional 3D printing methods often involve the extrusion of preformed polymers or in-situ generation of monomers to create solid materials. While these approaches are increasingly accessible, they are limited by issues like long printing times, low resolution, and difficulties with micron-sized features. To address these shortcomings, researchers have turned to photo-polymerization – a faster, more precise process that produces polymers through light irradiation.

The Limitations of Single-Light Source Photopolymerization

Most photo-polymerization reactions rely on a single light source, which restricts both the reaction time and spatial accuracy. Despite the use of photoactivation agents, these processes often suffer from inadequate control over the reaction, allowing unwanted spreading or prolonged activation, leading to suboptimal results. Furthermore, the maximum achievable spatial resolution is limited by diffraction, hindering the development of nanometric-scale features.

Breaking the Mold: Two-Light Source Photopolymerization

To overcome these challenges, research groups have explored the use of two distinct light sources to control the photopolymerization reaction. This approach has the potential to create new lithography and 3D printing technologies with enhanced capabilities. However, the complexity of these methods has relegated them to the realm of the unknown.

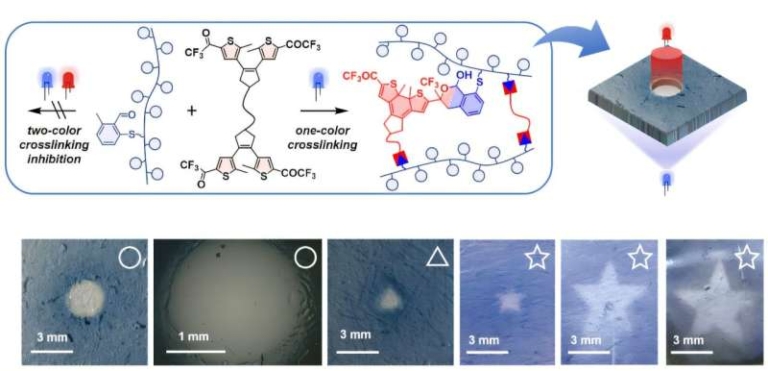

Innovative Photopolymerization Technique: AUV-RED Reactivity

Researchers from the UAB, led by Jordi Hernando, in collaboration with Professor Christopher Barner-Kowollik from the University of Technology of Queensland, Australia, have developed an innovative photopolymerization process using a two-color, two-light antagonistic system. The team enabled the formation of solid polymer networks with controlled forms and resolutions below the millimeter scale. This breakthrough is poised to transform the field of lithography and 3D printing.

How it Works

The new process employs a complex chemical reaction involving a Cycloadition Oxa-Dales-Alder, where pre-polymers activated by ultraviolet (UV) light undergo a reaction with hardening agents, which alternate between reactive and non-reactive states depending on the color of the light applied. This dual-light system allows for precise control over the hardening process, enabling the creation of solid materials with defined forms and resolutions below the millimeter scale.

Horizon for Lithography and 3D Printing

The potential applications of this cutting-edge technology are vast. The UAB researchers plan to explore the use of their innovative approach to improve the performance of 3D printing processes and achieve resolutions in the submicronic range. This represents significant progress in the technology, bringing us one step closer to unlocking the full potential of 3D printing.

Long-term Impact and Future Applications

As our reliance on additive manufacturing continues to grow, the need for precision, efficiency, and control becomes increasingly paramount. The UAB breakthrough has provided a crucial stepping stone toward the next generation of 3D printing technologies, driving us closer to the realization of complex structures and functional materials with unprecedented properties.