High-strength bolts are the most common structural element in steel structure construction, and all steel structural engineers are extremely familiar with them. However, this may not be the case. Today we will start with the most basic concepts and take you to re-understand high tensile bolts, which can turn your most basic understanding upside down.

What are high tensile bolts

High strength friction bolt, the literal English translation is: high strength friction preload bolt, English abbreviation: HSFG. It can be seen that the high-strength bolts we refer to in Chinese construction are the abbreviation of high-strength friction preload bolts. In daily communication, the words “friction” and “adhesion” are simply used, which has caused many engineers and technicians to understand the basic definition of high-strength bolts and led to misunderstandings.

Misunderstanding 1:

Are bolts with material grade above 8.8 “high strength bolts”?

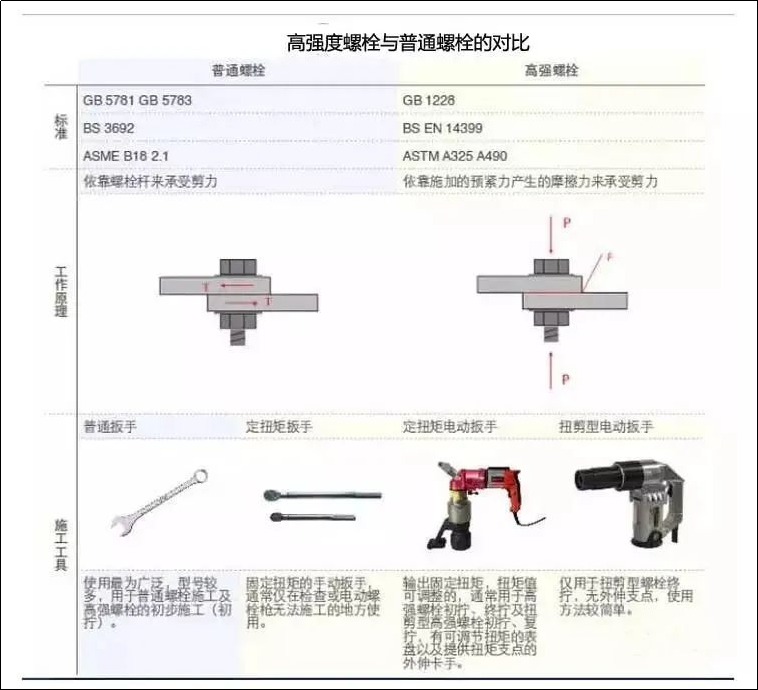

The main difference between high-strength bolts and ordinary bolts is not in the strength of the material used, but in the form of force. The key is whether to apply a preload force and use static friction to resist shear.

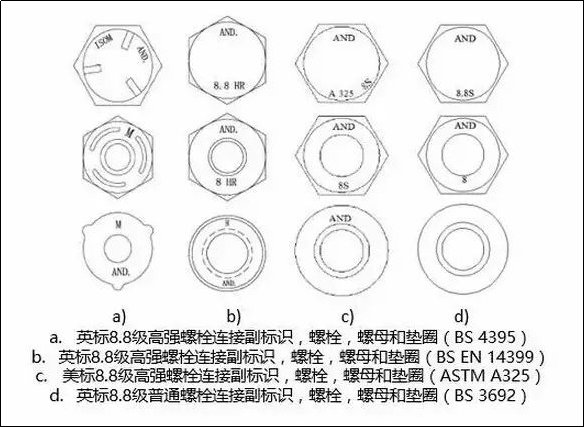

In fact, high strength bolts (HSFG BOLT) mentioned in British and American standards are only grade 8.8 and 10.9 (BS EN 14399 / ASTM-A325&ASTM-490), while ordinary bolts include grade 4.6, 8.8 , 10.9. , 12.9, etc. (BS 3692 11 models Table 2); It can be seen that material strength is not the key to distinguishing high-strength bolts from ordinary bolts.

Correctly understand “high strength” and where is the strength?

According to GB50017, calculate the tensile and shear strength of a single ordinary bolt (class B) of grade 8.8 and a high-strength bolt of grade 8.8.

Through calculation, we can see that under the same grade, the design values of tensile strength and shear strength of ordinary bolts are higher than those of high-strength bolts.

So where is the “strong” in high-strength bolts?

In order to answer this question, we need to start from the design operating conditions of the two bolts, study their elastoplastic deformation laws, and understand the limit state when the design is damaged.

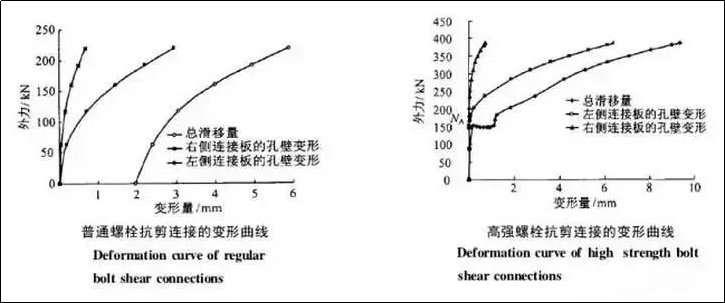

Stress-strain curves of ordinary bolts and high-strength bolts under working conditions

Limit state in case of design failure

Ordinary bolts: the screw itself undergoes plastic deformation beyond the allowable design and the screw is sheared.

In ordinary bolted joints, relative slip occurs between the connecting plates before they begin to support a shear force. Then, the bolt shank and the connection plate come into contact, undergo elastoplastic deformation, and bear the shear force.

High-strength bolts: Static friction between the effective friction surfaces is overcome and relative displacement of the two steel plates occurs, which is considered damage in design terms.

In high-strength bolted joints, the friction force first supports the shear force. When the load increases to the point where the friction force is not sufficient to resist the shear force, the static friction force is overcome and the connecting plates slide relative to each other. other (limit state). However, although it is damaged at this time, the bolt shank is in contact with the connection plate and can still use its own elasto-plastic deformation to resist the shear force.

Misunderstanding 2:

The load capacity of high strength bolts is higher than that of ordinary bolts. Is this called “high strength”?

It can be seen from the calculation of a single bolt that the design strength of high tensile and shear strength bolts is lower than that of ordinary bolts. The essence of its high strength lies in the fact that in normal operation the nodes do not allow any relative sliding, that is, the elasto-plastic deformation is small and the rigidity of the nodes is large.

It can be seen that under the given design node load, nodes designed with high strength bolts do not necessarily save the number of bolts used, but they have low deformation, high rigidity and safety reserve high. It is suitable for main beams and other locations that require greater joint stiffness, and conforms to the basic seismic design principle “strong nodes, weak elements”.

The strength of high-strength bolts lies not in the design value of their own bearing capacity, but in the rigidity of their design nodes, high safety performance and strong resistance to damage.

Comparison of high strength bolts and ordinary bolts

There are big differences in construction inspection methods between ordinary bolts and high-strength bolts due to their different design stress principles.

The mechanical performance requirements of ordinary bolts of the same quality are slightly higher than those of high-strength bolts, but high-strength bolts have one more impact energy acceptance requirement than ordinary bolts.

Marking of ordinary bolts and high-strength bolts is the basic method for on-site identification of bolts of the same quality. Since British and American standards have different calculation values for the torque values of high tensile bolts, it is also necessary to identify the bolts of the two standards.

High strength bolts: (M24, L60, grade 8.8)

Ordinary bolts: (M24, L60, grade 8.8)

It can be seen that ordinary bolts cost about 70% of the price of high strength bolts. In combination with the comparison of their acceptance requirements, it can be concluded that the premium should be to ensure the impact energy performance (toughness) of the material. .

To summarize

For a seemingly simple problem, it is not easy to understand it deeply, completely and correctly. The difference between the definition, meaning and significance of high-strength bolts and ordinary bolts is the basic premise that allows us to correctly understand, use high-strength bolts and carry out construction management.

point of view

1) It is indeed mentioned in some works on steel structures that high strength bolts refer to bolts whose strength exceeds class 8.8. Regarding this view, first of all, the British and American standards do not support it and do not define “strong” and “weak” for a specific intensity level. Second, it does not meet the “high strength bolts” mentioned in our work.

2) For ease of comparison, the stress of the complex bolt group is not considered here.

3) High-strength pressure bolts are also designed considering the pressing force of the screw, which will be introduced in detail in “High-strength bolt comparison between pressure and friction types” later.

What do you know about high tensile bolts?

The full name of high-strength bolts is called high-strength bolt connection pair in production, and it is generally not called high-strength bolts for short.

According to the installation characteristics, they are divided into: large hex head bolts and twist shear bolts. Among them, the torsion shear type is only used at level 10.9.

According to the performance level of high strength bolts, they are divided into: level 8.8 and level 10.9. Among them, grade 8.8 only has high-strength large hex bolts. In terms of marking method, the number before the decimal point indicates the tensile strength after heat treatment, the number after the decimal point indicates the yield strength ratio, which is the ratio; from the measured value of yield strength to the measured value of tensile strength. Grade 8.8 means that the tensile strength of the bolt shank is not less than 800 MPa and the yield/strength ratio is 0.8; grade 10.9 means that the tensile strength of the bolt shank is not less than 1000 MPa, and the yield/strength ratio is 0.8. the ratio is 0.9.

In structural design, the diameters of high-strength bolts generally include M16/M20/M22/M24/M27/M30, but M22/M27 is the second series of choices. Under normal circumstances, M16/M20/M24/M30 is the main choice. .

High-strength bolts are divided into pressure-type high-strength bolts and friction-type high-strength bolts according to the design requirements in terms of shear strength design.

The bearing capacity of the friction type depends on the anti-slip coefficient of the force-transmitting friction surface and the number of friction surfaces. The friction coefficient of red rust after sandblasting (firing) is the highest, but from the actual operating point. From a point of view, it greatly depends on the level of construction. Many supervisory units all asked if standards could be lowered to ensure project quality.

The load capacity of the pressure resistant type depends on the minimum shear capacity of the bolt and the load capacity of the bolt. When there is only one connection surface, the shear bearing capacity of M16 friction type is 21.6 ~ 45.0 kN, while the shear bearing capacity of M16 pressure bearing type is 39.2~48.6kN, which is better than friction type.

In terms of installation, the pressure type process is simpler, and the connection surface only needs to be cleaned of oil stains and floating rust. The tensile bearing capacity in the direction of the shaft is written very interestingly in the specifications of the steel structure. The design value of friction type is equal to 0.8 times the pretension force, and the design value of pressure type is equal to the effective area of the screw multiplied. by the design value of the tensile strength of the material. It seems like there is a big difference, in fact the two values are basically the same.

When simultaneously bearing shear force and tensile force in the direction of the rod axis, the friction type requirement is that the ratio of the shear force carried by the bolt to the bearing capacity in shear plus the stress ratio of the axial force of the screw to the tensile bearing capacity is less than 1.0, and the requirement of the pressure bearing type is the shear force and the shear bearing capacity of the bolt The square of the ratio plus the square of the ratio between the axial force of the screw and the tensile bearing capacity is less than 1.0, that is, under the same load combination, the design safety reserve of high-strength bolts under pressure. the same diameter should be larger than friction type high strength bolts.

Since the friction surface of the connection may break under repeated strong earthquakes, the shear bearing capacity at this time still depends on the shear strength of the bolt and the pressure bearing capacity of the plate. Therefore, the seismic code stipulates the ultimate shear limit. high strength bolts. Formula for calculating bearing capacity.

Although the pressure type has an advantage in design values because it is a compression and shear failure type, the bolt hole is a porous type bolt hole similar to an ordinary bolt, and the deformation when subjected to load is much greater than that. friction type, so the high strength bolts cannot bear the pressure. This type is mainly used for the connection of non-seismic components, the connection of components that do not support dynamic loads, and the connection of non-repeating components.

The normal service limit states of these two types are also different:

Friction type connection refers to the relative sliding of the friction surface of the connection under the action of the basic combination of loads;

Connection under pressure refers to the relative sliding between connecting parts under the action of a standard combination of loads;

Ordinary bolts

1. Ordinary bolts are divided into three types: A, B and C. The first two are refined bolts and are rarely used. Generally speaking, ordinary bolts refer to ordinary C-class bolts.

2. In some temporary connections and connections that need to be dismantled, ordinary C-grade bolts are commonly used. Commonly used bolts in building structures include M16, M20 and M24. Some raw bolts in the mechanical industry may have larger diameters and are used for special purposes.

High strength bolts

3. The materials of high-strength bolts are different from those of ordinary bolts. High strength bolts are generally used for permanent connections. Commonly used ones include M16~M30. High-strength oversized bolts have unstable performance and should be used with caution.

4. Bolted connections of major components of the building structure generally use high-strength bolted connections.

5. High strength bolts shipped from factory are not classified as pressure type or friction type.

6. Are these high strength friction bolts or high strength pressure resistant bolts? In fact, there are differences in design calculation methods:

1) High-strength friction-type bolts consider sliding between plates as the limit state of bearing capacity.

2) For high-strength pressure-resistant bolts, sliding between plates is considered as the normal service limit state, and connection breakage is considered as the bearing capacity limit state.

7. Bolts with high friction strength cannot fully utilize the potential of bolts. In practical applications, high strength friction type bolts should be used for very large structures or structures that support dynamic loads, especially where the load causes reverse stress. At this point, the unused potential of the bolts can be used as a safety reserve. . In other locations, high-strength, pressure-resistant bolted joints should be used to reduce construction costs.

The difference between ordinary bolts and high strength bolts

8. Ordinary bolts can be reused, but high strength bolts cannot be reused.

9. High-strength bolts are generally made of high-strength steel (No. 45 (8.8s) steel, 20MmTiB (10.9S)), which are pre-tensioned bolts. For friction types, use a torque wrench to apply the specified preload. and for pressure types, unscrew the Torx head. Ordinary bolts are usually made of ordinary steel (Q235) and only need to be tightened.

10. Ordinary bolts are generally grade 4.4, grade 4.8, grade 5.6 and grade 8.8. High tensile bolts are typically grades 8.8 and 10.9, with grade 10.9 being the most common.

11. The screw holes of ordinary bolts are not necessarily larger than those of high-strength bolts. In fact, regular bolt holes are relatively small.

12. Grade A and B screw holes of ordinary bolts are generally only 0.3-0.5mm larger than bolts. Class C screw holes are typically 1.0-1.5mm larger than bolts.

13. Friction-type high-strength bolts rely on friction to transmit load, so the difference between the screw shank and the screw hole can reach 1.5-2.0mm.

14. The force transmission characteristics of high-strength bolts under pressure should ensure that under normal use, the shear force does not exceed the friction force, which is the same as that of high-strength bolts friction type. When the load increases again, relative slippage occurs between the connecting plates. The connection relies on the shear strength of the screw and the pressure of the hole wall to transmit force. It is the same as ordinary bolts, so the difference between screws. and the screw hole is slightly smaller, 1.0~1.5mm.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.